Impact test bed of magneto-rheological damper and impact test device

A magneto-rheological shock absorber and impact test technology, which is applied in the direction of impact test, measuring device, machine/structural component test, etc., can solve the problem of blank dynamic characteristics of magnetorheological shock absorber, and achieve rapid improvement Effects of maneuverability, weight reduction, and reduced recoil stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

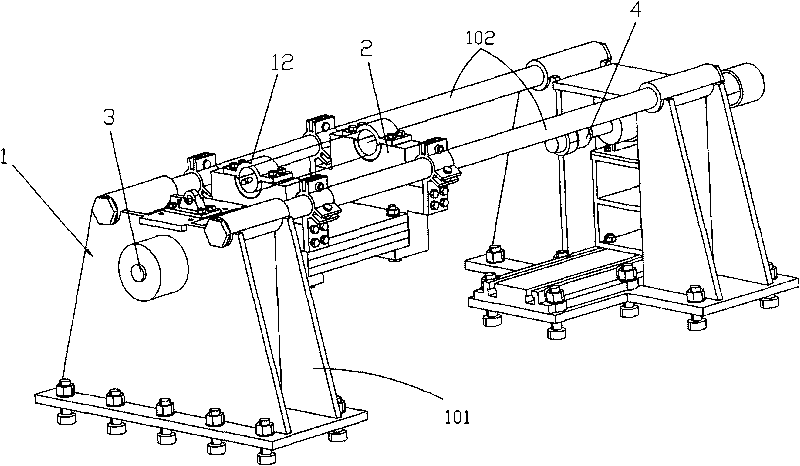

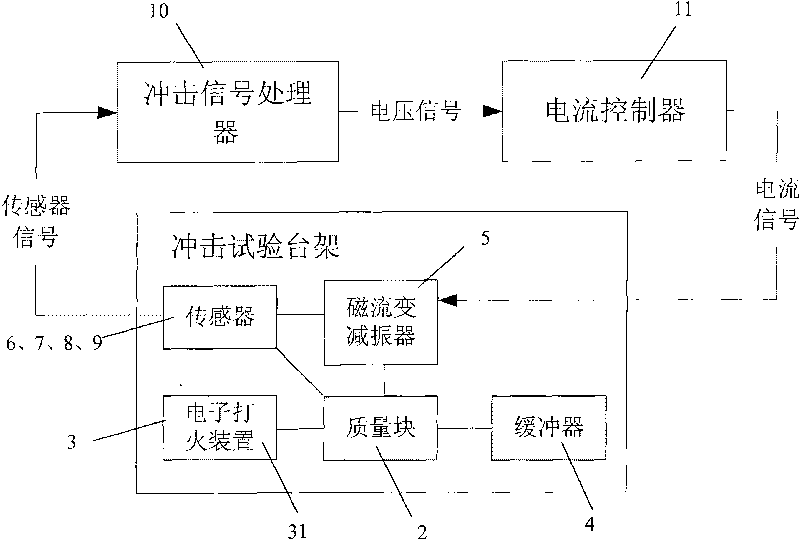

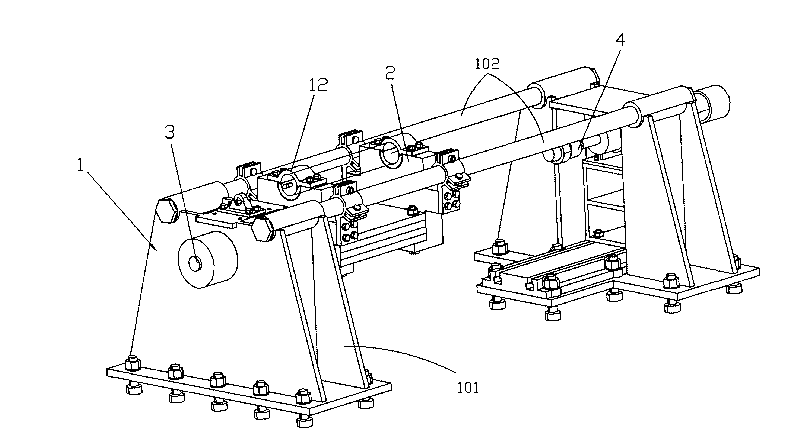

[0026] see figure 1 , figure 2 , the magnetorheological shock absorber impact test device of the present invention, it comprises, bench 1, mass block 2, impact generating device 3, buffer 4, magnetorheological shock absorber 5, acceleration sensor 6, impact force sensor 7 , pressure sensor 8, speed and displacement sensor 9; impact signal processor 10,

[0027] Platform 1, which includes two bases 101 and several guide rails 102 horizontally arranged on the two bases 101; mass block 2, which is slidably arranged on the guide rails 102;

[0028] The impact generation device 3 is provided with one end of the guide rail, including an electronic ignition device 31, a powder chamber and a closed explosion generator, the electronic ignition device is connected with the powder chamber, and the powder chamber is connected with the closed explosion generator. are connected, and the dense explosion generator is connected to the mass block through a pipeline;

[0029] The buffer 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com