Heat pump or heat exchange device with periodic positive and reverse pumping

A heat exchange device and pumping technology, applied in the field of heat exchange, can solve problems such as lack of active control, and achieve the effect of reducing the accumulation of impurities or pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0211] The method of the present invention will be further described in detail below in conjunction with the drawings and the embodiments of the present invention.

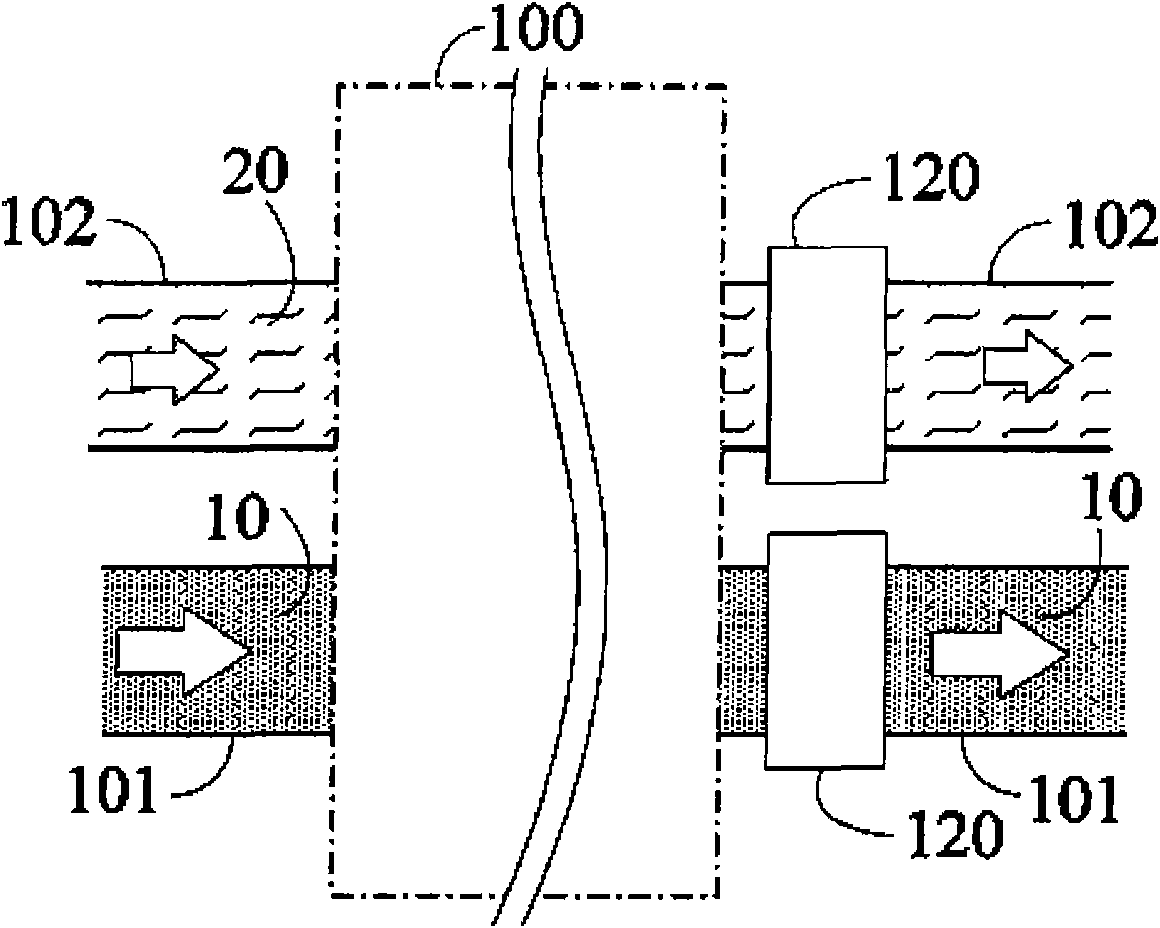

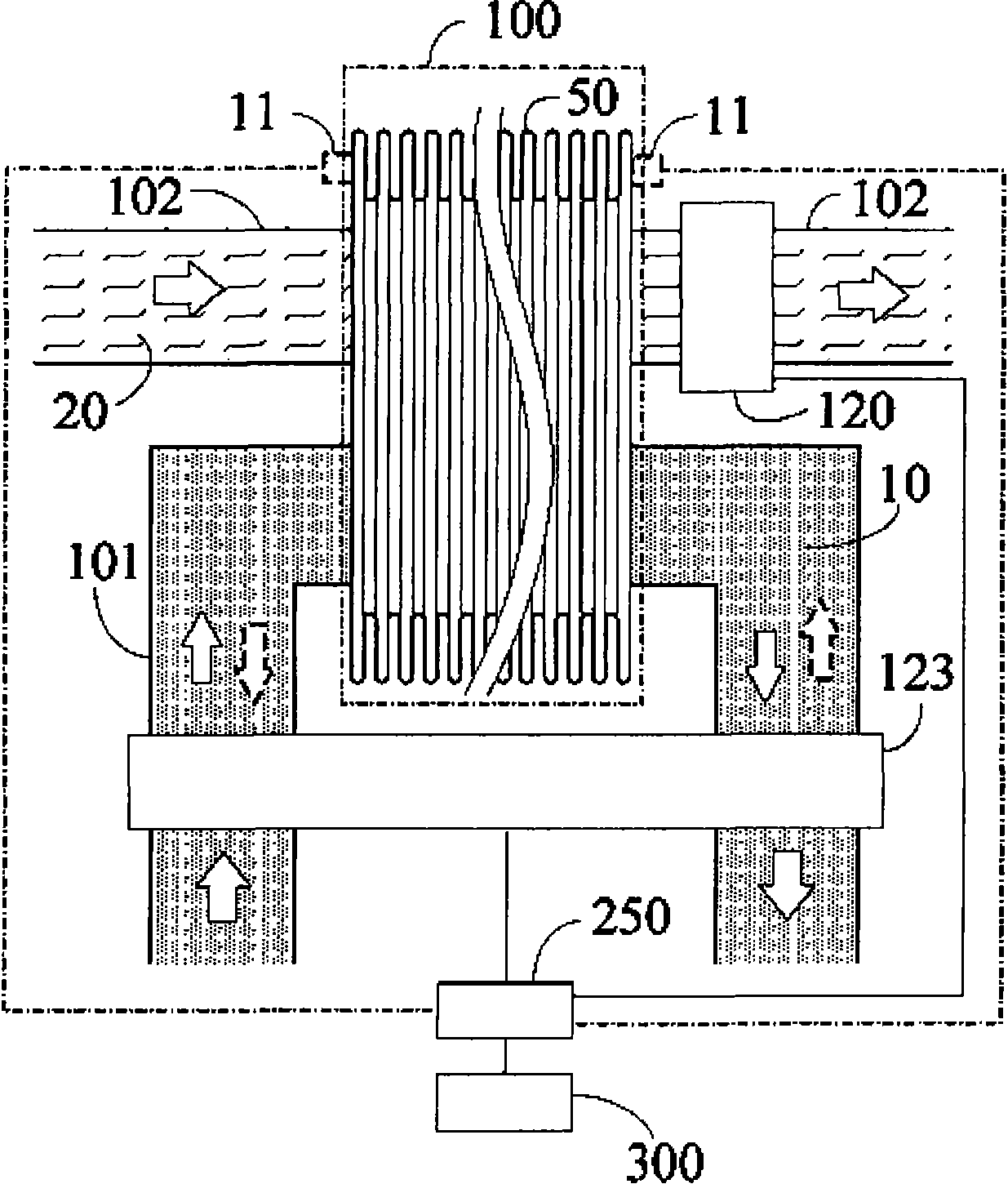

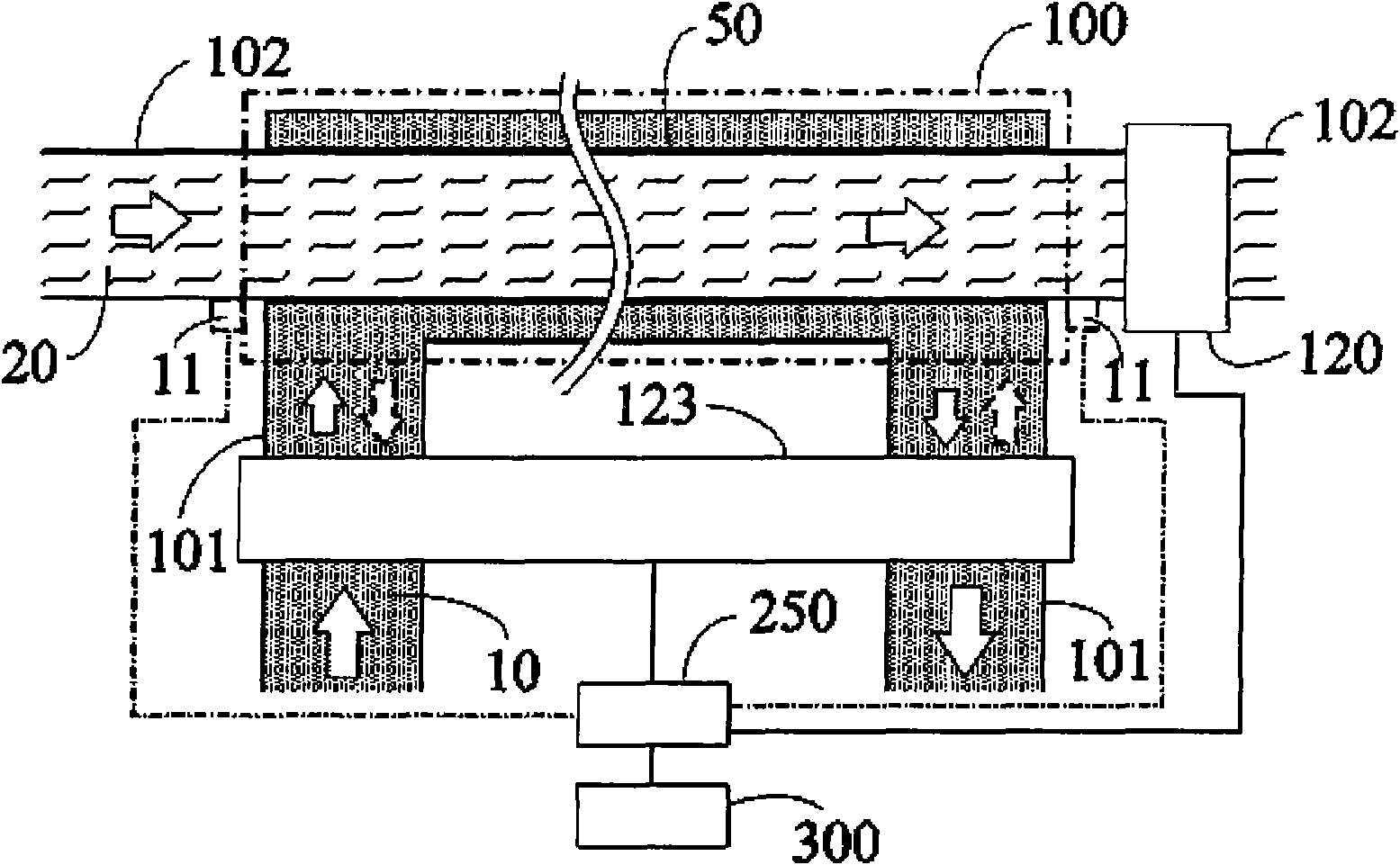

[0212] figure 2 It is a block diagram of the structure principle of the present invention in which the primary-side fluid pipeline and the secondary-side fluid pipeline are jointly arranged on the heat conductor to form a heat pump or heat exchange device function, and are driven by the fluid bidirectional pumping device; figure 2 Shown: This is a heat pump or heat exchange device 100 that pumps in forward and reverse cycles, and is further connected in series to be driven by a power source 300 and controlled by a fluid cycle reversing control device 250 to pump fluid in cycles forward and reverse. The moving device 123 is used to make the pumped flow through the primary fluid pipeline 101, and the primary fluid 10 through the heat pump or the heat exchange device 100 changes its flow direction periodically; wherein:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com