Anti-blocking composite filter element

A composite filter element and anti-clogging technology, applied in the direction of filtration separation, filtration loop, mobile filter element filter, etc., can solve the problems of large filtration resistance, difficult to clean, limited contact area between the filter layer and the material liquid, etc., to prevent clogging, The effect of reducing the accumulation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

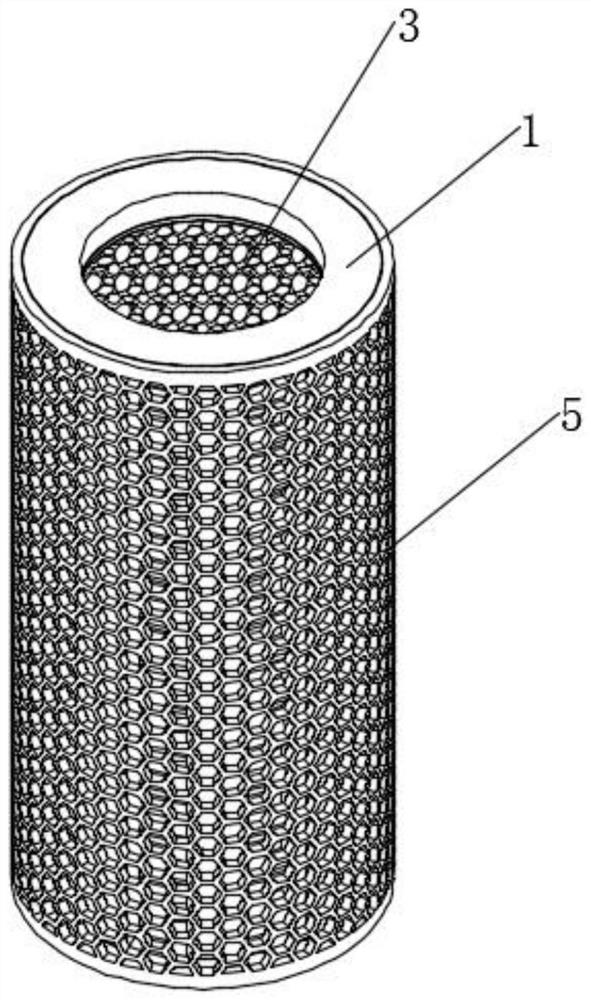

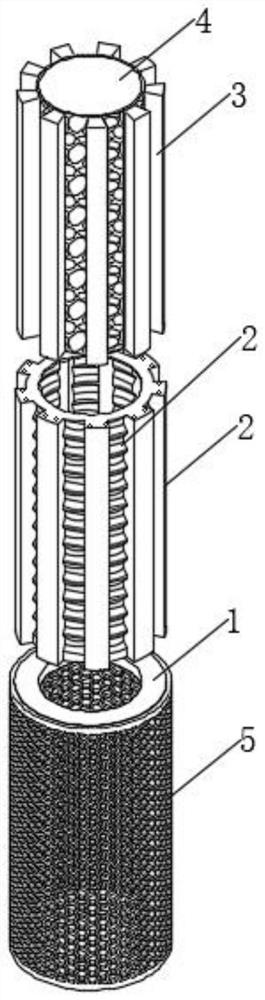

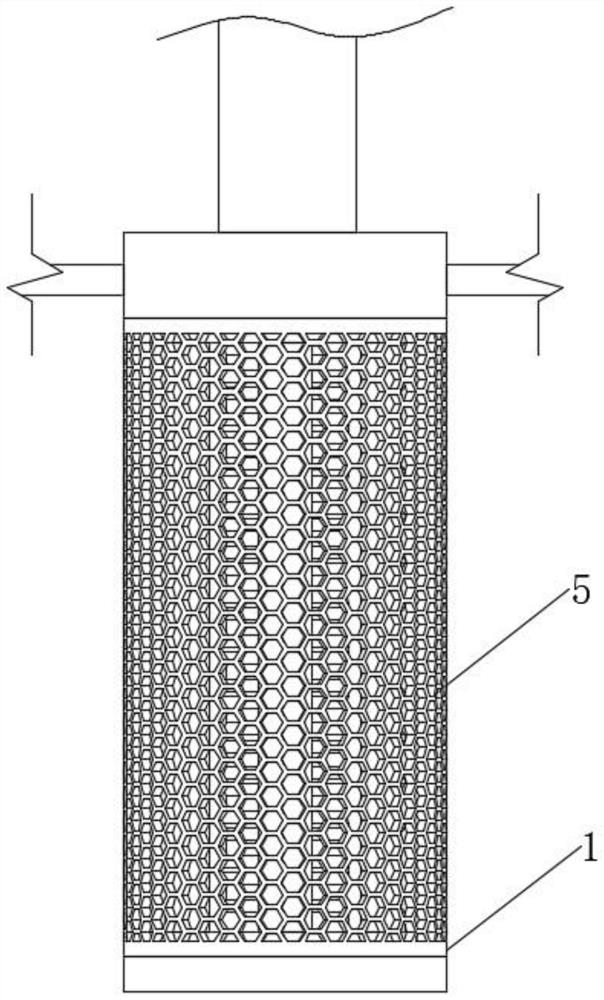

[0042] see Figure 1-6, an anti-clogging composite filter element, comprising a pair of sealing rings 1, a main filter ring 2 is fixedly connected between the pair of sealing rings 1, the main filter ring 2 includes a plurality of evenly distributed fixed columns 201, one of the fixed columns 201 There is a row of spray holes on the opposite side walls, and a filter column 202 is connected between the two adjacent fixed columns 201. The filter column 202 includes a fixed plate matched with the inner filter belt 403, and the upper limit of the fixed plate is fixedly connected to both ends with a For the inclined plate, there are a plurality of evenly distributed filter holes on the inclined plate. The water flows between the rings 2 collide with each other, so that the micro-particle impurities in the water flow fully contact the adsorption thorns 501 and the outer filter ring 5 . A floating column 3 is slidably connected in the fixed column 201, the floating column 3 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com