Novel clutch

A technology of clutches and overrunning clutches, applied in clutches, one-way clutches, mechanical equipment, etc., can solve problems such as friction loss, achieve the effect of reducing friction pairs and improving adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

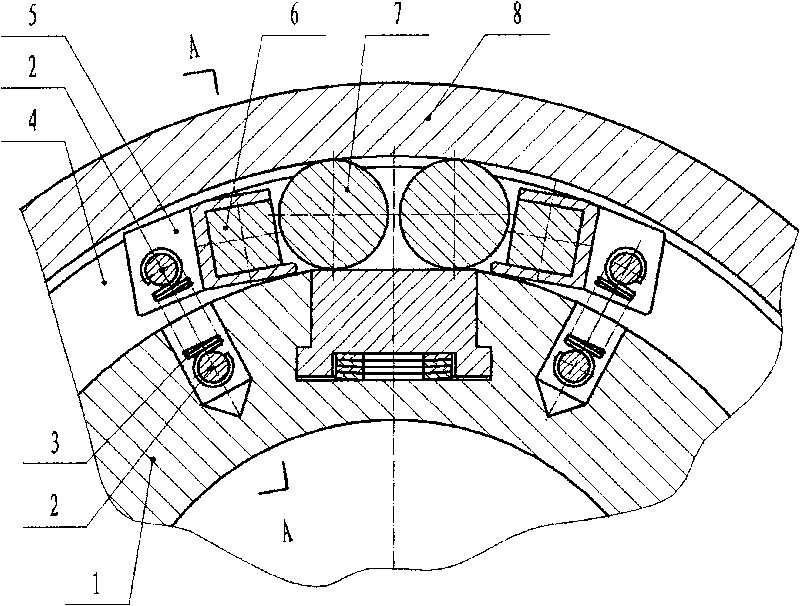

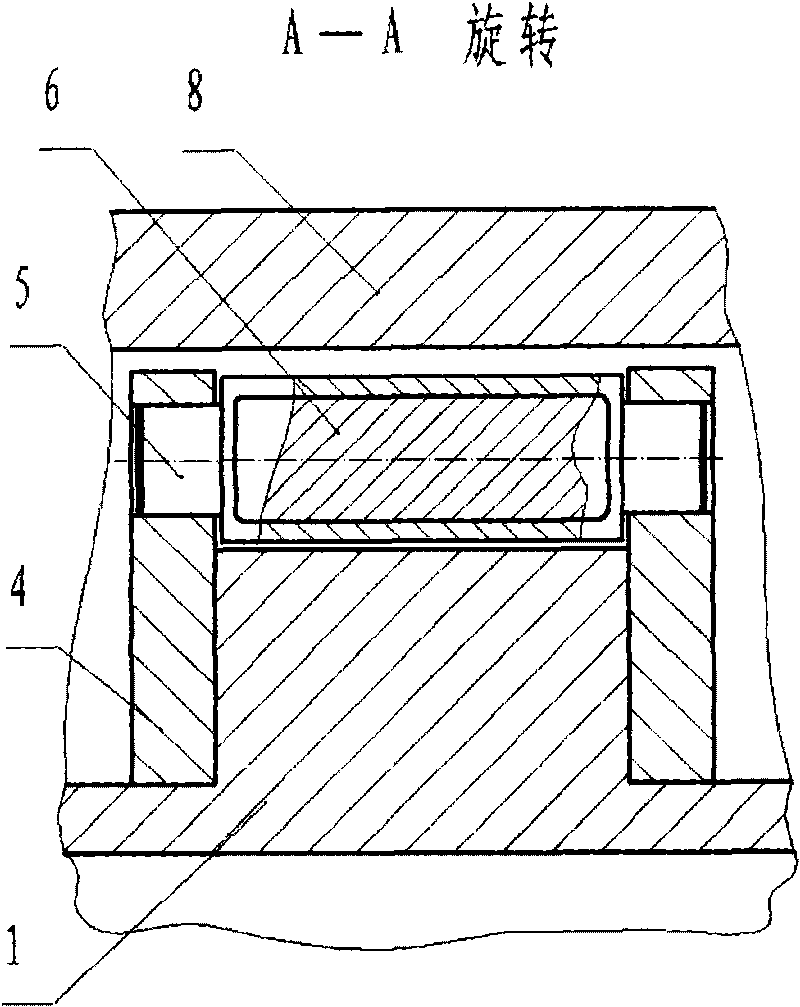

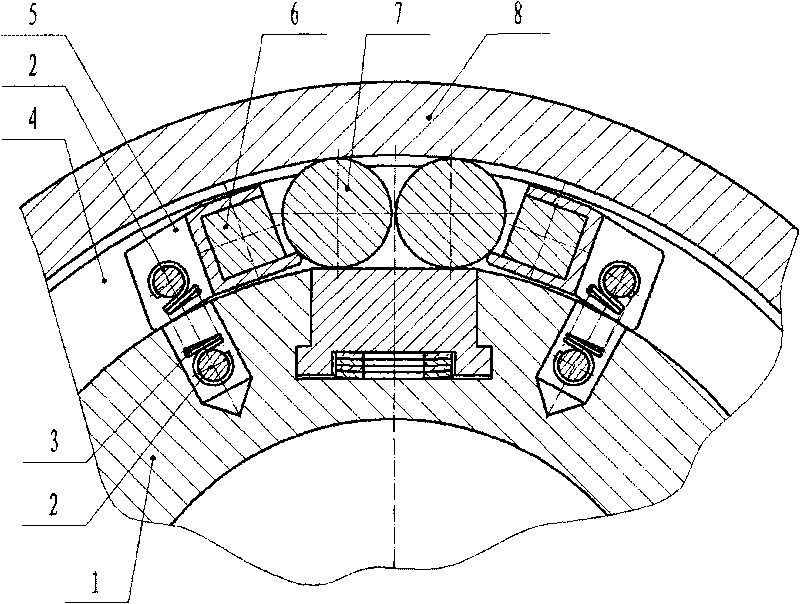

[0017] Below, the present invention will be further described in detail in conjunction with the accompanying drawings.

[0018] As can be seen in the accompanying drawings, the mechanism has a combination improvement mechanism of a roller positioning mechanism of a roller type overrunning clutch and a centrifugal mechanical clutch mechanism or a roller positioning mechanism of a roller type overrunning clutch and a roller type The combined improvement mechanism of the mechanical brake mechanism is characterized in that the middle centrifugal block mechanism in the centrifugal mechanical clutch mechanism or the roller tightening mechanism in the roller mechanical brake mechanism is removed, and a roller type overrunning clutch is used. The magnet 6 mechanism in the column positioning mechanism sucks the roller 7 in the mechanism to the working position, and the inner star wheel 1 near the positions of the magnets in the improved centrifugal mechanical clutch mechanism or roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com