Internal combustion engine

A technology for an internal combustion engine and a diesel engine, applied in the field of a two-stroke diesel engine, can solve problems such as high thermal load, and achieve the effects of large material throughput, inexpensive structure, and high functional safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

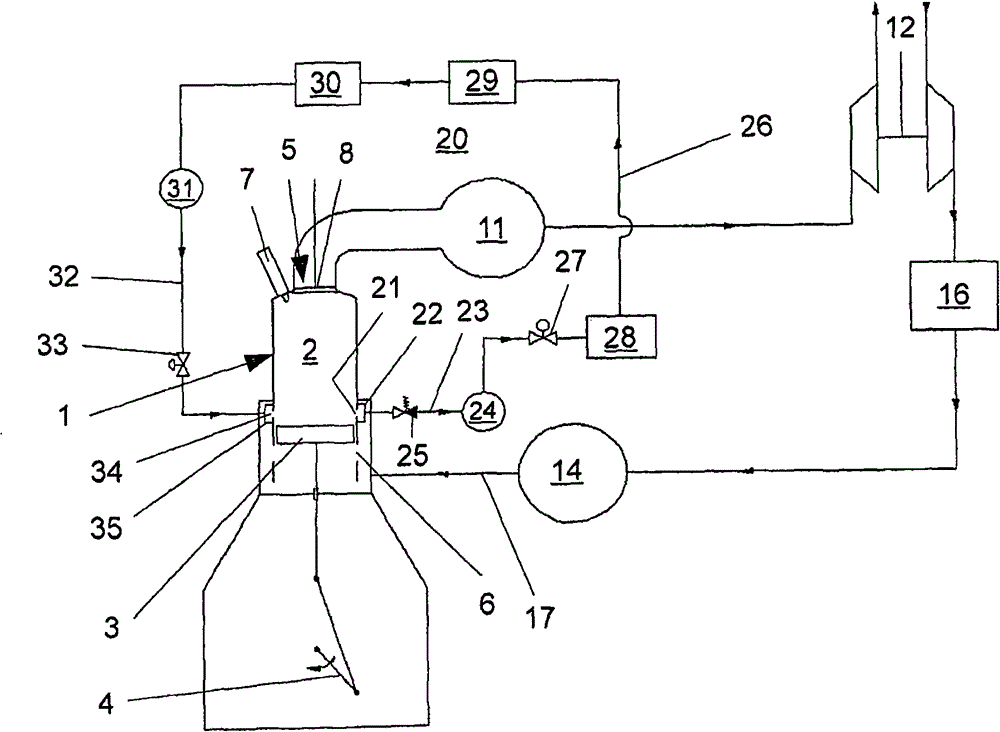

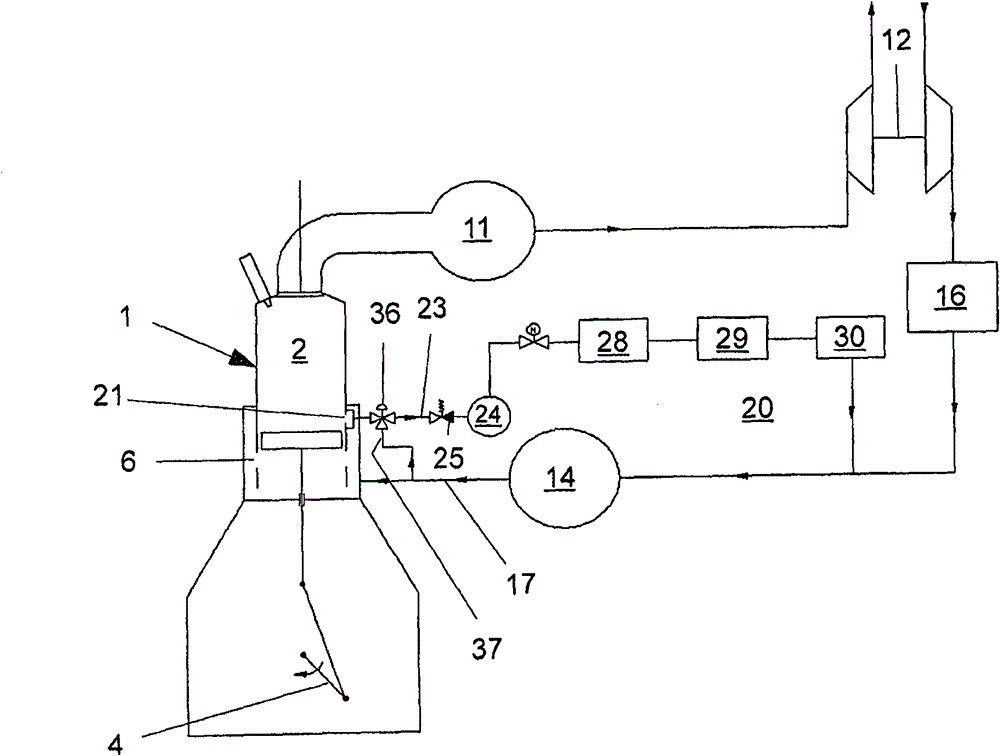

[0041] The main field of application of the invention is large diesel engines, especially two-stroke large diesel engines, for example as drives for ships or stationary power plants or similar applications, but the invention is not restricted thereto. based on Figures 1 to 3 An example of this two-stroke large diesel engine is shown.

[0042] This diesel engine usually contains multiple cylinders, in Figures 1 to 3 Only one of the cylinders 1 is visible in each case. The cylinders 1 each have a cylinder liner, not described in detail here, which is received on the engine block. The cylinder liner contains a working chamber 2 functioning as a combustion chamber, which is delimited by a reciprocating, vertically moving piston 3 in the drawing. Piston 3 interacts with crankshaft 4 via a usual transmission element. Working chamber 2 is loaded with fuel and oxygen-containing flushing gas for the combustion process during each working stroke. Gases generated by the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com