Integrated burner with back step precombustion stage and V-groove main combustion stage

A back step and pre-combustion stage technology, applied in the field of back step pre-combustion stage plus v-groove main combustion stage integrated burner, can solve the problems of not being able to apply the engine, difficult outlet temperature field distribution, etc., to achieve a good flame The effect of stability and reliability of joint flame, widening of stable working range, and strong stable fire ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

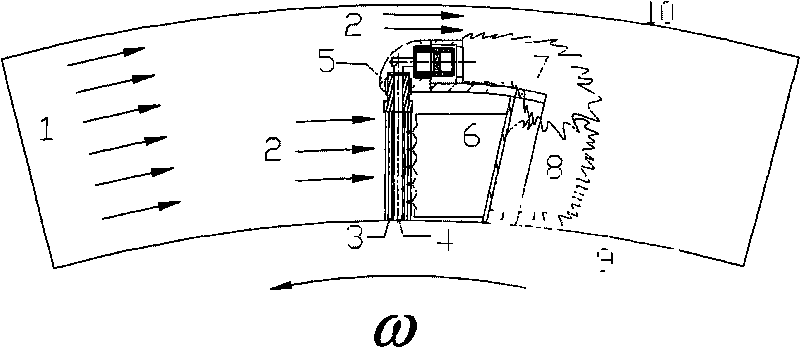

[0027] The integrated burner of the present invention is mainly suitable for rotary engines and other combustion chambers with strong centrifugal acceleration, and can provide a stable high-level and stable fire source for the combustion system of rotary engines. And good low-level combustion efficiency ensures that the entire combustion system has a wide stable working range and efficient combustion.

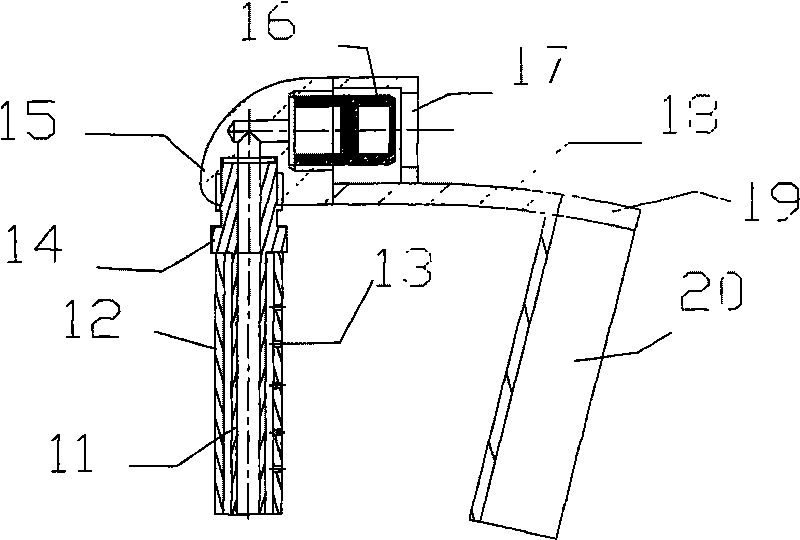

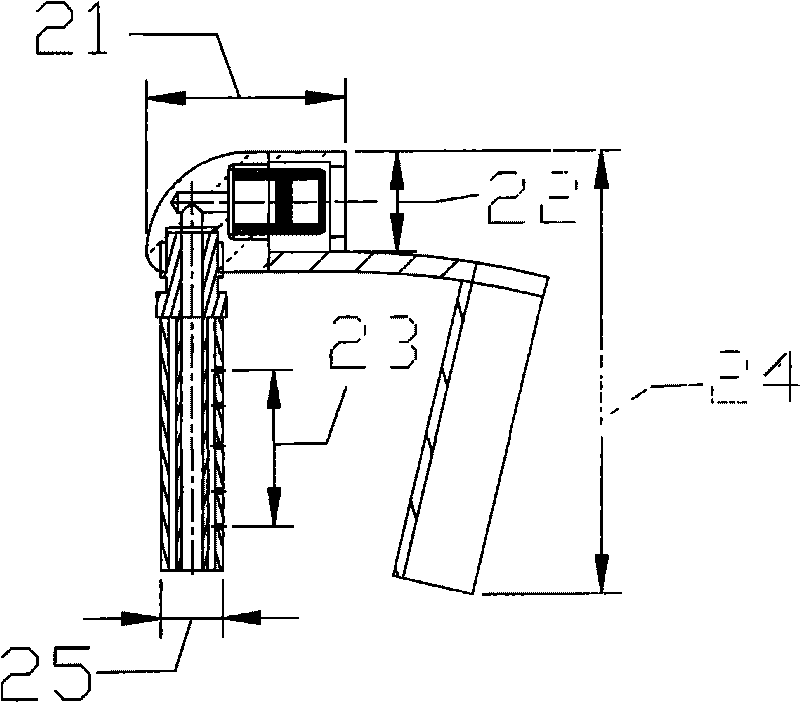

[0028] Such as figure 2As shown, the back stepped pre-combustion stage of the present invention plus the v-shaped groove type main combustion stage integrated burner 5 is mainly composed of a rear stepped pre-combustion stage and a v-shaped groove type main combustion stage, and the main combustion stage is mainly composed of Provides a stable fuel supply to the combustion chamber and ensures atomization. The rear stepped pre-combustion stage and the v-groove main combustion stage are fixed on the inner wall 9 of the combustion chamber and rotate together with the combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com