Deep well drilling waterpower deslagging device of floor anchor rod hole of tunnel

A deep hole drilling and bolt hole technology, which is applied in the installation of bolts, shaft equipment, earth-moving drilling, etc., can solve the problems of restricting the increase of the drilling speed of bolt holes and poor slag discharge effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

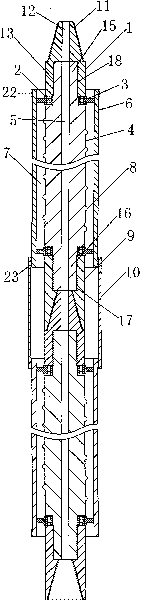

[0010] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

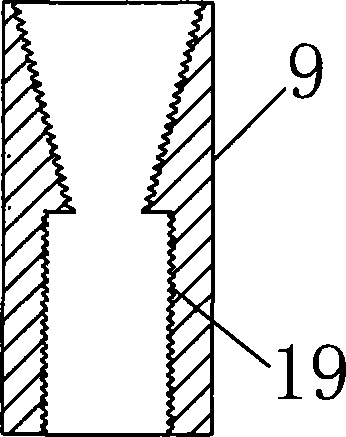

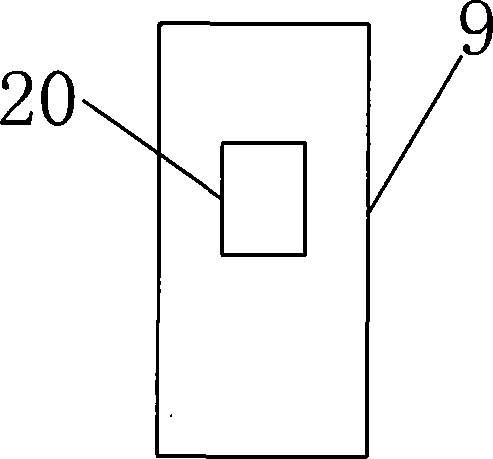

[0011] Depend on Figure 1-Figure 6 Given, the structure of the present invention is that there is a drill rod 4 with two ends extending out of the sleeve in the sleeve 6, the upper end of the drill rod 4 is connected with the upper interface connector 1, the lower end of the drill rod is connected with the lower interface connector 9, and the drill rod 4 is connected with the upper interface connector 1. The upper and lower ends of the rod 4 are fixed together with the sleeve 6 through the sealed bearing 2 and the bearing sleeve connector 3 to form a slag discharge structure with a drainage and slag discharge channel 7. There is a spiral surrounding the drill pipe 4 The ring rib 8 and the drill pipe 4 have a water inlet channel 5, and the slag discharge structure is connected to each other through the sleeve connecting pipe 10....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com