Fiber cable core structure for steel wire rope

A fiber rope and wire rope technology, applied in textiles, papermaking, textile cables, etc., can solve the problems of insufficient supporting force of wire rope strands, affecting the overall performance of the wire rope, poor softness, etc., to increase the number of strands, increase the oil content of the core, The effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

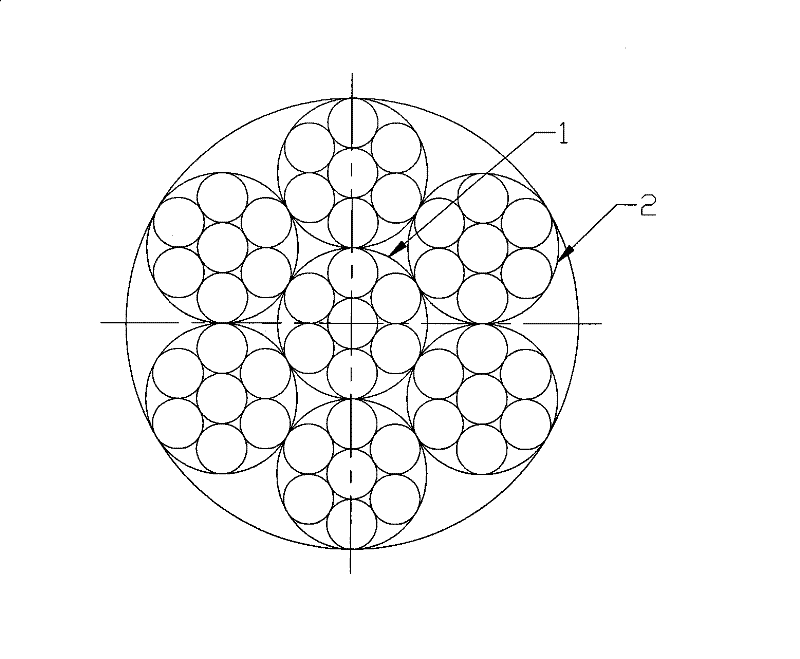

[0016] See figure 1 , The steel wire rope fiber core structure, including the central strand 1 and the outer strand 2, the central strand 1 and the outer strand 2 are made of helical twisting of multiple hemp yarns or artificial synthetic fibers. The outer layer strands 2 are evenly distributed close to the surface of the central strand 1 and have the same shape. Two adjacent strands are in close contact. The number of outer layer strands can be 4, 5, 6, 7 or 8 strands.

[0017] Select the lay length multiple of the fiber rope core, calculate and determine the diameter of the central strand and the outer strand according to the diameter of the fiber rope core and the lay length multiple. Select the lay length multiple of the core strand, and calculate and determine the required hemp yarn count and root number according to the diameter of the central strand, the outer layer strand, the number of outer strands and the lay length multiple of the core strand. Twist raw hemp yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com