Surface refining process for high-carbon chromium (GCr15) bearing after carbonitriding treatment

A carbonitriding and high-carbon chromium technology, which is applied in the field of surface refinement technology after carbonitriding of high-carbon chromium bearings, can solve the problems of bearing failure, large tensile stress, and reducing the beneficial effects of high paralympic content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

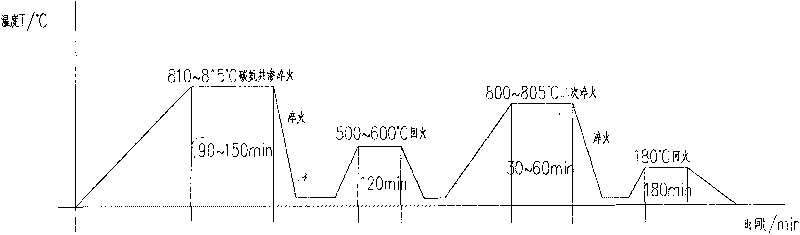

[0009] Example 1: Heat the bearing ring to 810°C, keep the carbon potential at 1.0-1.5 in a carbon-nitrogen atmosphere, and keep the nitrogen potential at 2-6% for 1.0 hour, then quench it with 30°C oil, and then heat the bearing Heat the ring to 500°C for stress relief and tempering for 2 hours, then heat the bearing ring to 800°C for 0.5 hour, quench it with 30°C oil, and then heat the bearing ring to 150°C for 2 hours. After testing and testing, the surface residual austenite content is 25-30%, and the surface stress is 200-300Mpa compressive stress. After testing, there are no large carbonitrides on the surface, and the maximum carbonitride size is 25μm; enhanced fatigue life test After that, the minimum life of the test bearing is 801 hours, which is greater than 9L 10 (L 10 87 hours), a total of 8 sets of test bearings, the reliability is greater than 99.5%.

Embodiment 2

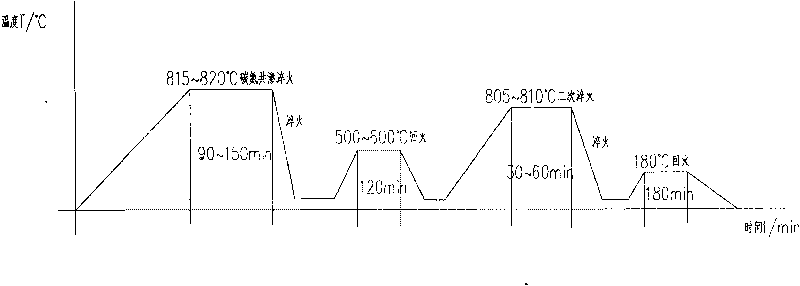

[0010] Example 2: Heat the bearing ring to 825°C, keep the carbon potential at 1.0-1.5 in a carbon-nitrogen atmosphere, and keep the nitrogen potential at 2-6% for 2.5 hours, then quench it with 65°C oil, and then put the bearing Heat the ring to 550°C for stress relief and tempering for 2.5 hours, then heat the bearing ring to 815°C for 1.2 hours, then quench it with 65°C oil, then heat the bearing ring to 180°C for 2.5 hours. After testing and testing, the surface residual austenite content is 27-35%, and the surface stress is 200-400Mpa compressive stress. After testing, there are no large carbonitrides on the surface, and the maximum carbonitride size is 20μm;; Enhanced fatigue life After the test, the minimum life of the test bearing is 889 hours, greater than 10L 10 (L 10 87 hours), a total of 8 sets of test bearings, the reliability is greater than 99.5%.

Embodiment 3

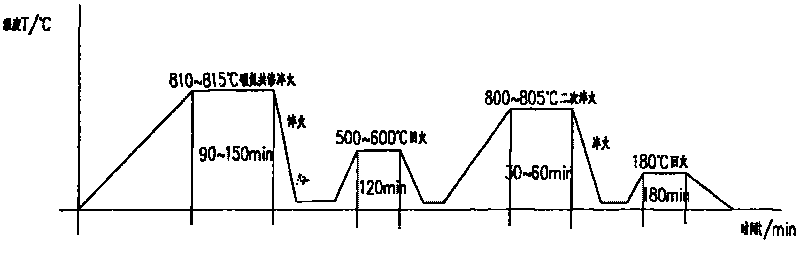

[0011] Example 3: Heat the bearing ring to 840°C, keep the carbon potential at 1.0-1.5 in the carbon-nitrogen atmosphere, and keep the nitrogen potential at 2-6% for 3 hours, then quench it with 100°C oil, and then the bearing The ring is heated to 600°C for stress relief and tempering for 3 hours, then the bearing ring is heated to 830°C for 1.5 hours, then quenched with 100°C oil, and then the bearing ring is heated to 200°C for 3 hours and tempered. After testing and testing, the surface residual austenite content is 27-35%, and the surface stress is 200-400Mpa compressive stress. After testing, there are no large carbonitrides on the surface, and the maximum carbonitride size is 20μm;; Enhanced fatigue life After the test, the minimum life of the test bearing is 889 hours, greater than 10L 10 (L 10 87 hours), a total of 8 sets of test bearings, the reliability is greater than 99.5%.

[0012] The testing of the above test bearings is carried out according to the bearing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface stress | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com