Process for producing natural travertine-imitated vitrified brick

A stone vitrified brick and production process technology, applied in the direction of manufacturing tools, metal processing equipment, surface polishing machine tools, etc., can solve the problems of poor control of hole size and position on the brick surface, regular shape of holes, etc., to achieve texture and hole Strong anti-fouling performance, good wear resistance, and wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

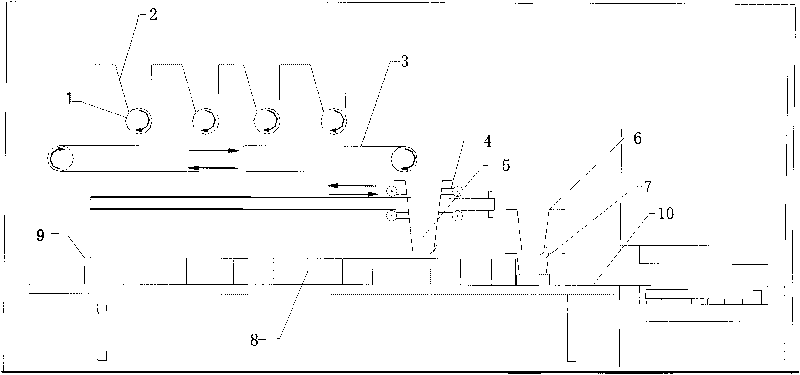

[0017] like figure 1 Shown; a production process of stone-like natural travertine vitrified bricks, the process is to put the basic fabric and travertine material into the fabric blanking drum 1 respectively through the drum hopper 2, there are four fabric blanking cylinders 1, and the travertine material It is on the middle fabric blanking drum 1, adjust the speed of the fabric blanking drum 1 to control the blanking ratio of the basic fabric and the travertine material, the fabric blanking drum 1 rotates to transfer the basic fabric and the travertine material to the feeding belt 3, and the feeding belt 3 Rotate to send the mixed fabric composed of basic fabric and travertine material to the mobile storage hopper 5. The mobile storage hopper 5 can be moved by the transmission of the guide rail and the guide wheel 4. With the movement of the mobile storage hopper 5, the mixed fabric is sent to the straight grain The forming grid 8 is finalized, the straight grain forming grid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com