Boiling chlorination furnace for preparing titanium tetrachloride by using natural rutile

A technology of boiling chlorination furnace and natural rutile, applied in titanium halide and other directions, can solve the problems of high investment cost and maintenance cost of furnace, complicated structure of boiling chlorination furnace, uneven particle size of high titanium slag, etc. The effect of maintenance cost, good flexibility, easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

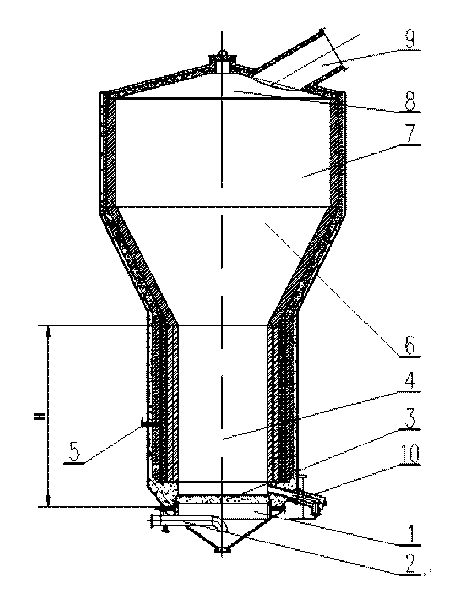

[0014] Embodiments of the present invention: this ebullating chlorination furnace for producing titanium tetrachloride with natural rutile has a cylindrical ebullated bed steel structure shell as a whole, and the structure is as follows figure 1 Shown, comprise boiling section 4, boiling section 4 connects expansion section 7 by transition section 6, the diameter of boiling section 4 is determined according to the unit area production capacity of required production capacity and boiling chlorination furnace, and its height H is 2-2 of this diameter 4 times, the ratio of the section area of the boiling section 4 to the cross-sectional area of the enlarging section 7 is reduced to 1:5.76. A slagging opening 10 is provided at the lower end of the boiling section 4, and a furnace bottom sealing cover 1 is sealed. The furnace bottom sealing cover 1 is also called a chlorine gas distribution chamber. A chlorine pipe 2 with the opening facing down is inserted in the furnace botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com