Protecting device of dissolving tank inner wall of alkali recovery furnace

A protection device and a technology of a dissolution tank, which is applied in the regeneration of lye, alkali metal compounds, alkali metal oxides/hydroxides, etc., and can solve the problem that the inner wall of the dissolution tank of an alkali recovery furnace is easily splashed by molten materials and dangerous equipment And the safety of operators, the leakage of alkali solution in the dissolution tank, etc., to achieve the effect of avoiding long-term corrosion, uniform water curtain, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

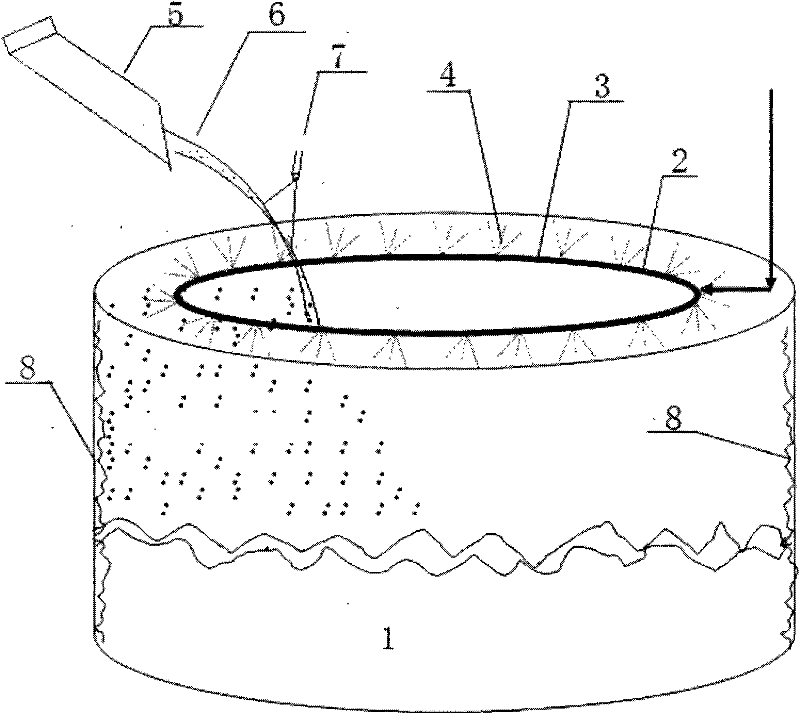

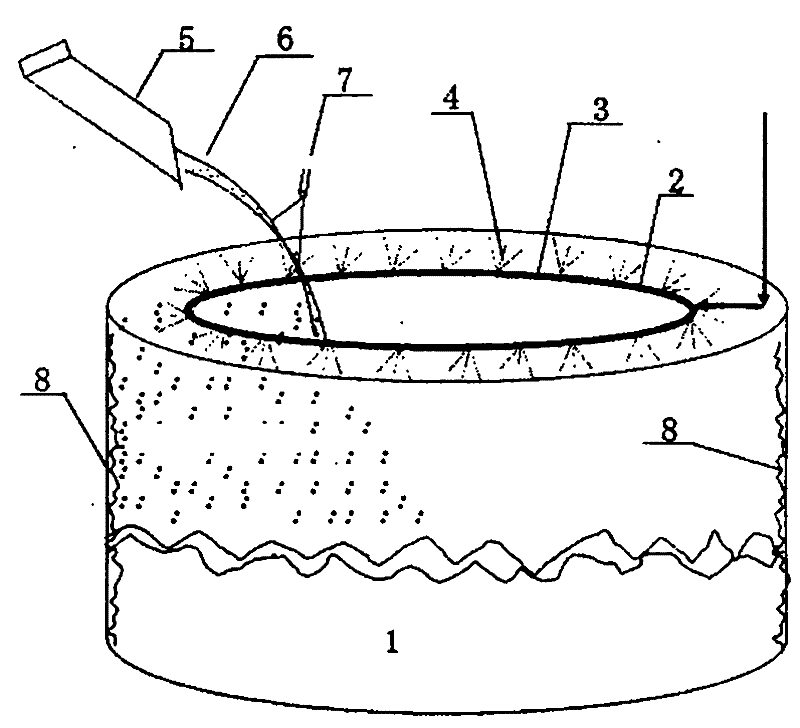

[0013] Example: such as figure 1 As shown, the molten material 6 flowing out of the chute 5 is broken up by the silencer steam 7, and distributed in the form of particles in the dissolution tank 1 of the alkali recovery furnace, most of which directly fall into the liquid surface of the dissolution tank 1 of the alkali recovery furnace , a small part flies to the inner wall of the dissolution tank 1 of the alkali recovery furnace. In order to prevent the molten material from directly contacting the inner wall of the dissolution tank 1 of the alkali recovery furnace, a liquid protection device 2 that allows the liquid to flow along the inner wall of the dissolution tank is provided on the dissolution tank 1 of the alkali recovery furnace. The liquid protection device 2 consists of a spray pipe 3 and The nozzle 4 is formed, and the spray pipe 3 is arranged on the top of the dissolution tank 1 of the alkali recovery furnace. For water, diluent or silencer, the nozzles 4 are even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com