Novel inflation-free tire

A technology of air-free tires and filling materials, which is applied to non-pneumatic tires, tire parts, transportation and packaging, etc. It can solve the problems of unsatisfactory, easy aging of pneumatic tires, and difficult heat dissipation, etc., and achieve good load performance and good heat dissipation effect , the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

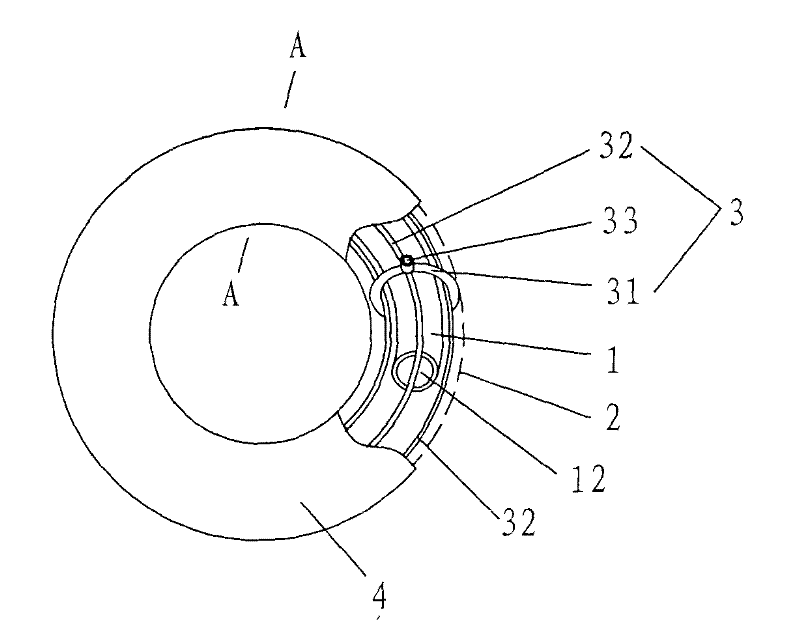

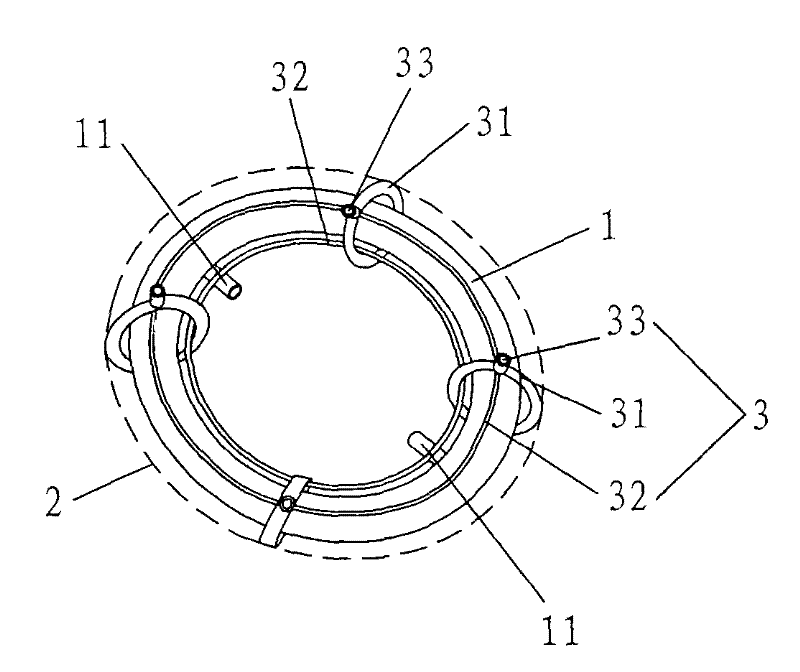

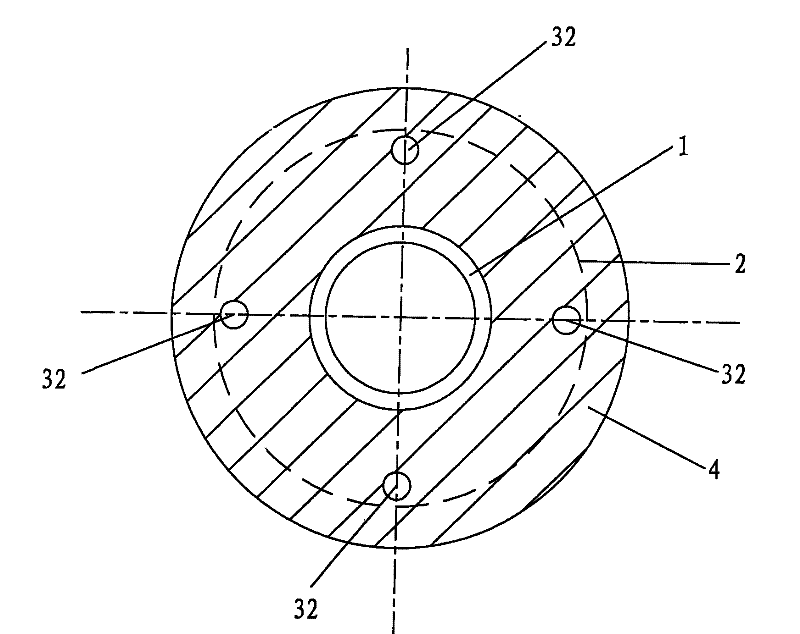

[0021] Such as figure 1 As shown, the present invention is a non-pneumatic tire, which is mainly composed of an inner ring tube 1, a mesh 2, a positioning device 3, and a filling material 4.

[0022] Such as figure 2 refer to figure 1 As shown, the inner ring pipe 1 is a circle made of a hollow pipe, and the material of the hollow pipe can be steel, high-strength plastic or the like. Two conduits 11 are arranged on the wall of the inner chamber 12 of the inner coil tube 1, the inner ends of the conduits 11 are connected to the wall of the inner chamber 12 of the inner coil tube 1, and the outer ends of the conduits 11 extend to the wall formed by the filling material 4. outside the surface of the tire. Since the conduit 11 communicates with the inner chamber 12 of the inner coil tube 1, the heat in the inner coil tube 1 can be dissipated through the conduit 11, and cooling water can also be injected into the inner chamber 12 of the inner coil tube 1 through the conduit 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com