Marking ink-jetting device for calculation of length of piled paper on crossing bridge of corrugated board production line

A technology for corrugated cardboard and inkjet devices, applied in the directions of jetting device, jetting device, electric device, etc., can solve problems such as affecting product appearance, sensor sending, error signal, etc., achieving sensitive response, convenient fixation, and reduction of base paper loss rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and examples.

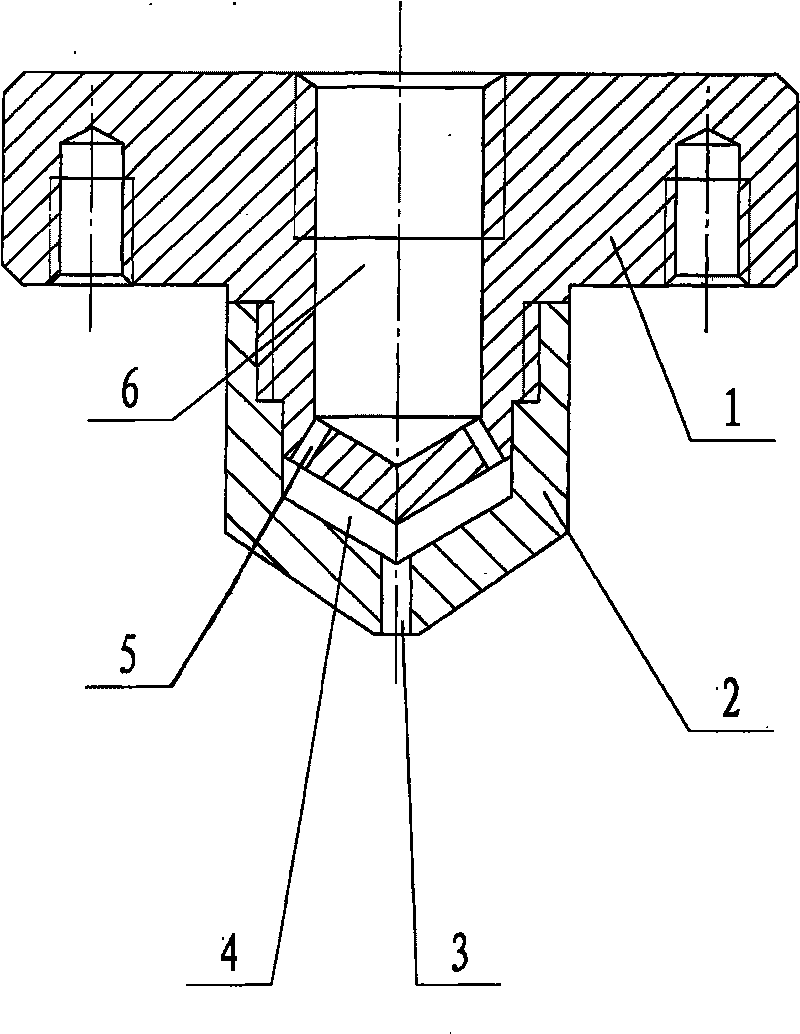

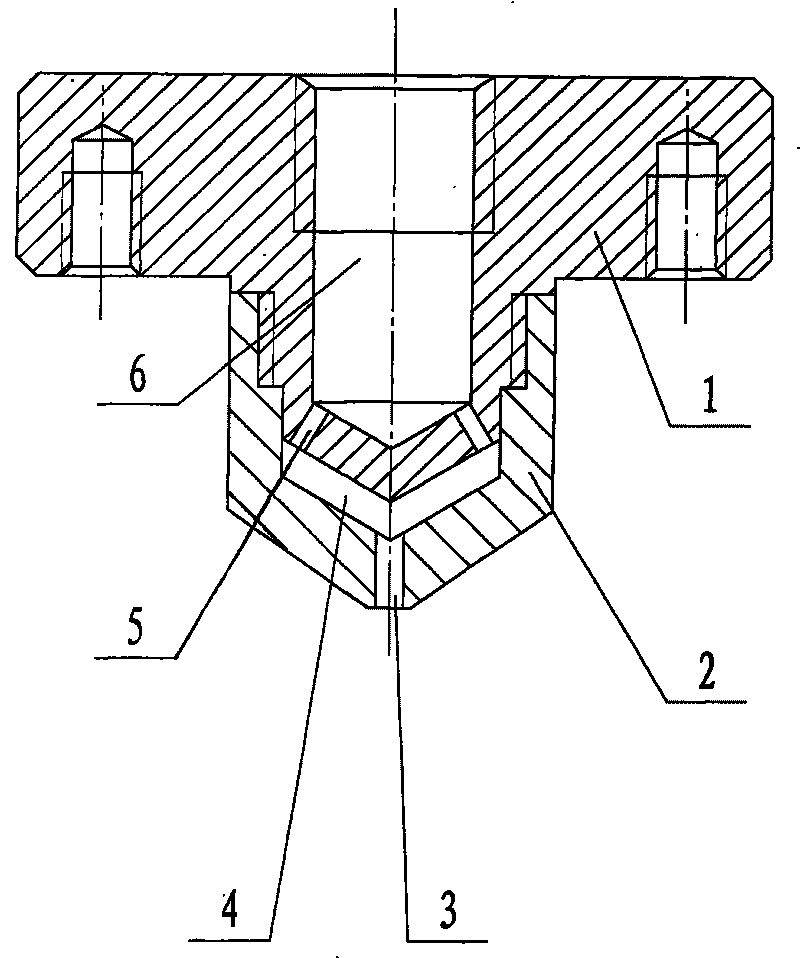

[0015] like figure 1 As shown, the marking inkjet device used for measuring the length of overpass paper in a corrugated cardboard production line in this example includes a nozzle body 1 installed above the corrugated paper belt, and the nozzle body 1 has a mixing chamber 6 at the upper end for connecting ink pipelines. The lower end of the nozzle body 1 is connected with a liquid cap 2 provided with an ink outlet hole 3. The specific connection method is that the nozzle body 1 and the liquid cap 2 pass through the internal thread arranged on the inner wall of the liquid cap 2 and the outer wall of the nozzle body 1. The external threads are screwed to each other. There is an atomizing chamber 4 in the form of a cavity between the nozzle body 1 and the liquid cap 2; the lower end of the nozzle body 1 is also provided with several crushing holes 5 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com