Novel stock fluid deironing method and device

A slurry and fluid technology, applied in the field of mineral beneficiation methods and devices, can solve the problems of many action steps, affecting the cleaning speed of the magnetic bar, and the magnetic bar cannot be put into use quickly, and achieves a technology with fewer action mechanisms and fewer cleaning steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

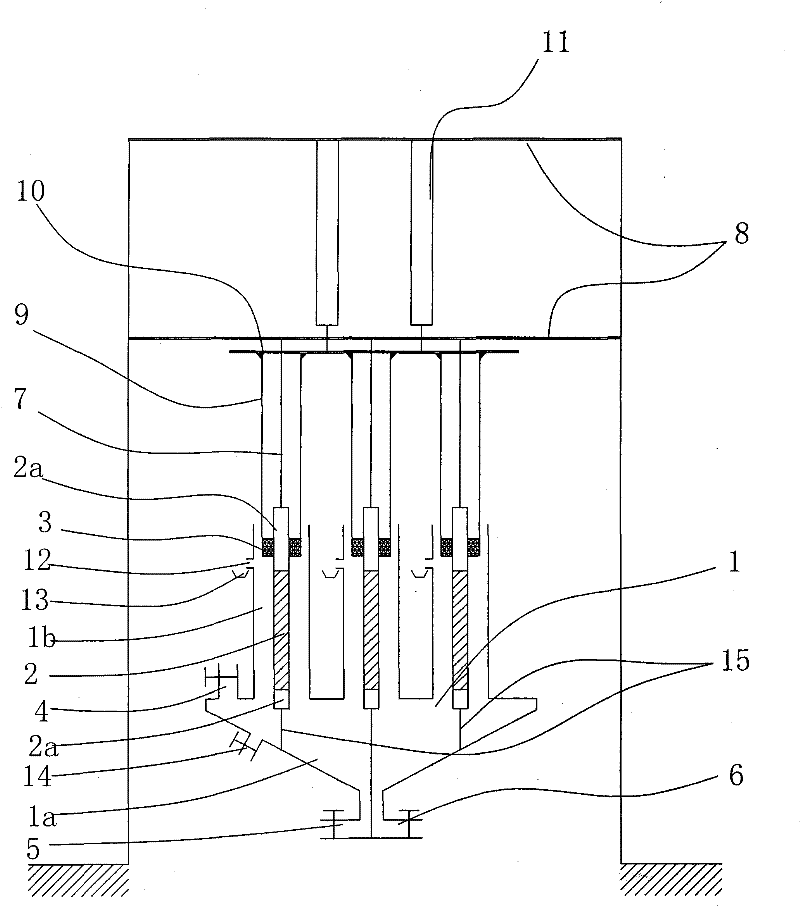

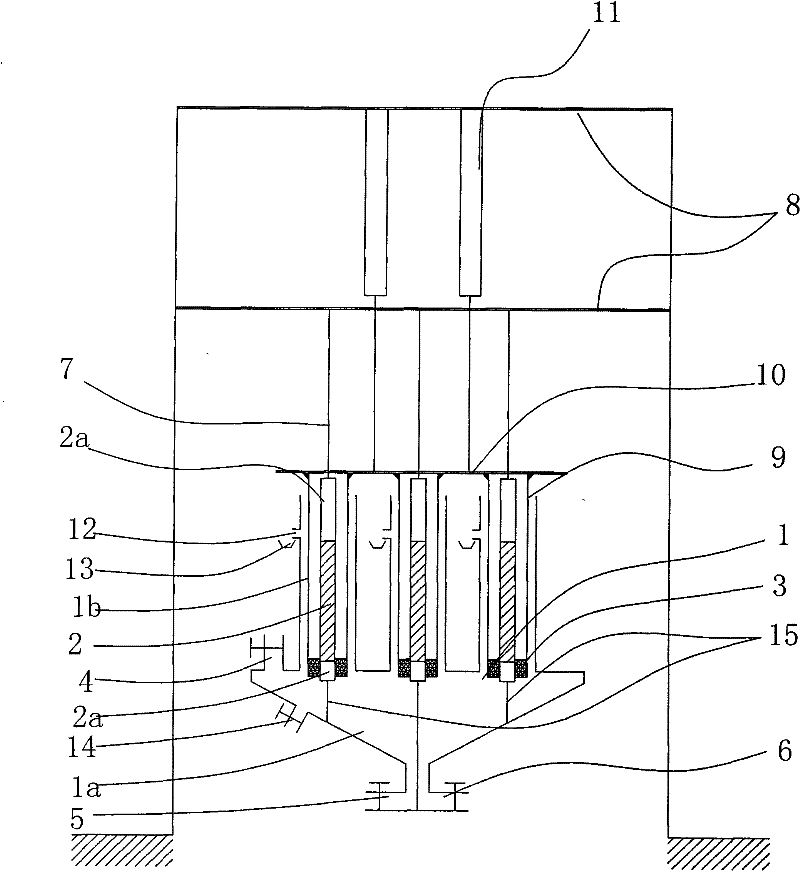

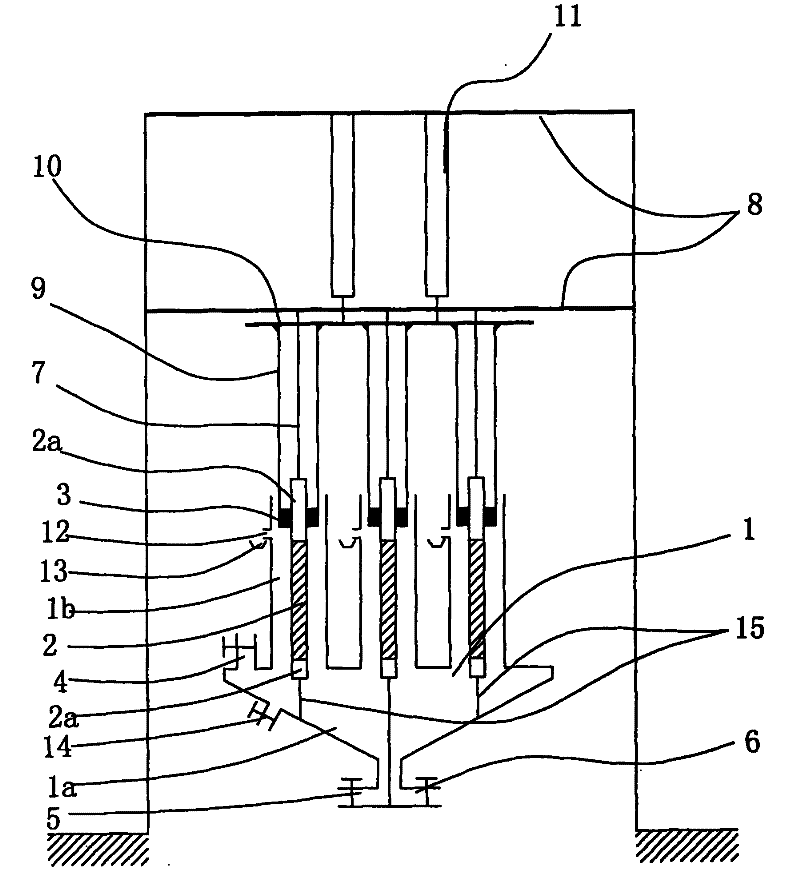

[0014] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0015] As shown in the figure, the new slurry fluid iron removal method of the present invention is realized in this way, including the slurry fluid iron removal process and the magnetic bar cleaning process. The slurry fluid iron removal process is that the slurry fluid flows from the bottom of the vertical cavity to After the permanent magnet rod installed vertically in the chamber to remove iron, it flows out from the outlet on the upper side of the chamber to the slurry tank; the cleaning process of the magnetic rod is to stop the iron removal process of the slurry fluid first, and remove the iron in the chamber. The slurry fluid is drained away, and then the scraper set on the top of the permanent magnet rod is moved down along the permanent magnet rod through the power mechanism, and the ferromagnetic substance attached to the permanent magnet rod is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com