Method for regulating speed of brushless direct current motor supplied with power by four-switch three-phase inverter

A brushed DC motor, three-phase inverter technology, applied in the direction of AC motor control, single motor speed/torque control, electrical components, etc. Fixed problems, low cost, and the effect of achieving stable and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

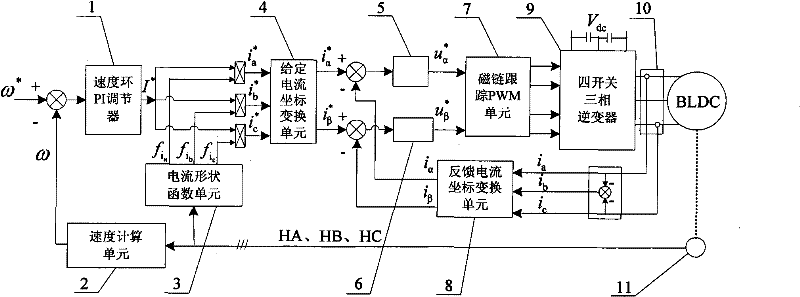

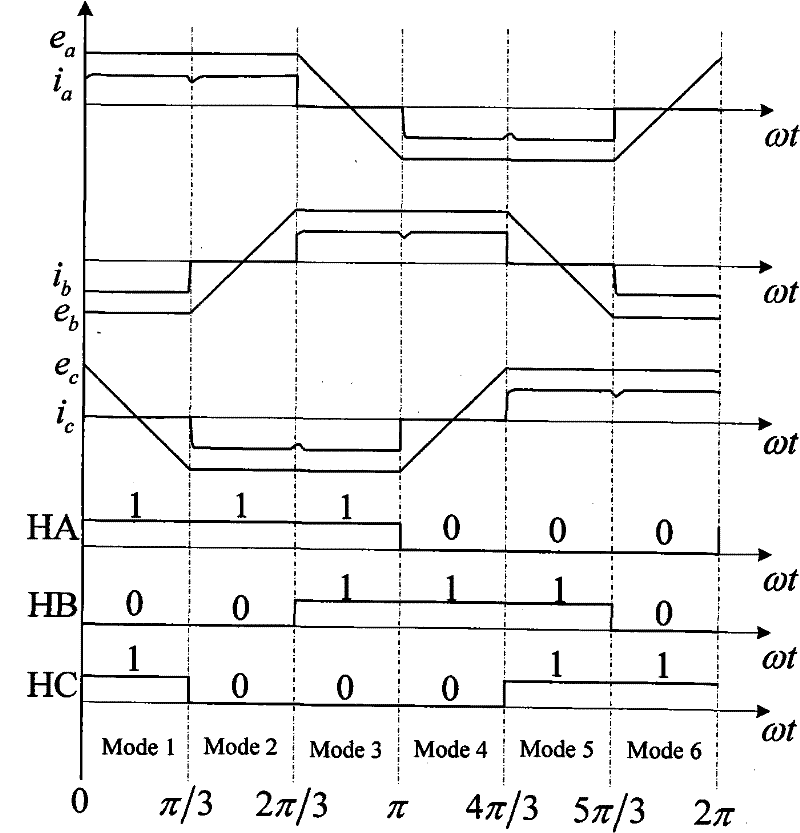

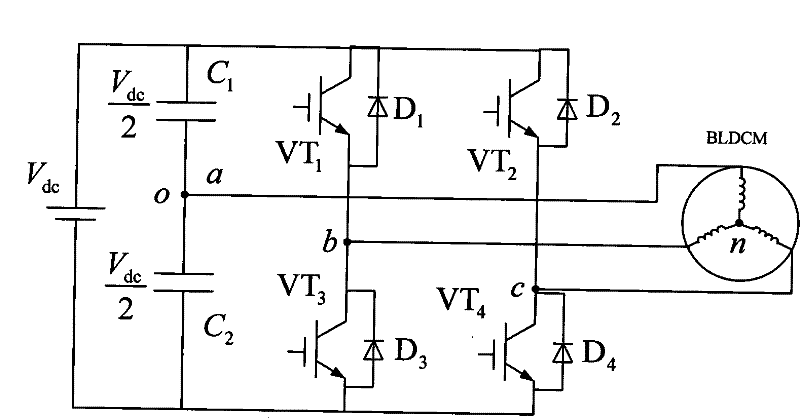

[0013] Specific implementation mode one: the following combination Figure 1-Figure 13 Describe this embodiment, which is based on a speed loop PI regulator 1, a speed calculation unit 2, a current shape function unit 3, a given current coordinate transformation unit 4, an α-axis current PI regulator 5, and a β-axis current PI regulator 6 , flux linkage tracking PWM unit 7, feedback current coordinate transformation unit 8, four-switch three-phase inverter 9, current sensor 10 and Hall magnetic pole sensor 11 are realized,

[0014] First, the Hall magnetic pole sensor 11 transmits the detected rotor angular velocity signal of the brushless DC motor to the speed calculation unit 2 and the current shape function unit 3 respectively; the current sensor 10 transmits the detected winding current of the brushless DC motor Passed to the feedback current coordinate transformation unit 8;

[0015] Then the speed calculation unit 2 calculates the rotational speed ω of the brushless DC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com