Method for improving balance of power-driven hanging basket working platform and electrical system

A technology of working platform and electrical system, which is applied in the direction of multiple motor speed adjustment, etc., can solve the problems that cannot fundamentally solve the problem of material falling accident, can not solve the problem of hoist tilting, and reduce the accident rate, so as to avoid people or materials from falling, The effect of accurate synchronization and avoiding hidden dangers of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

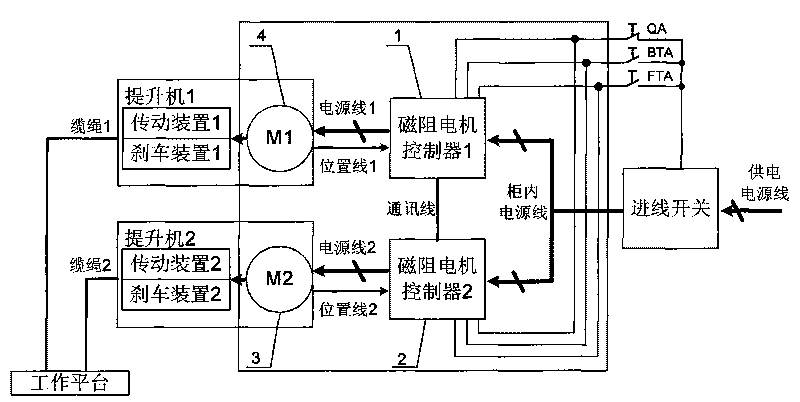

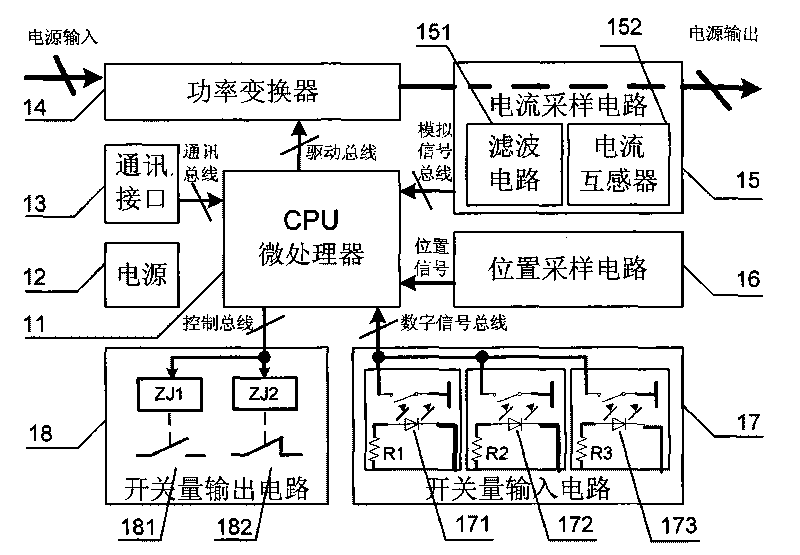

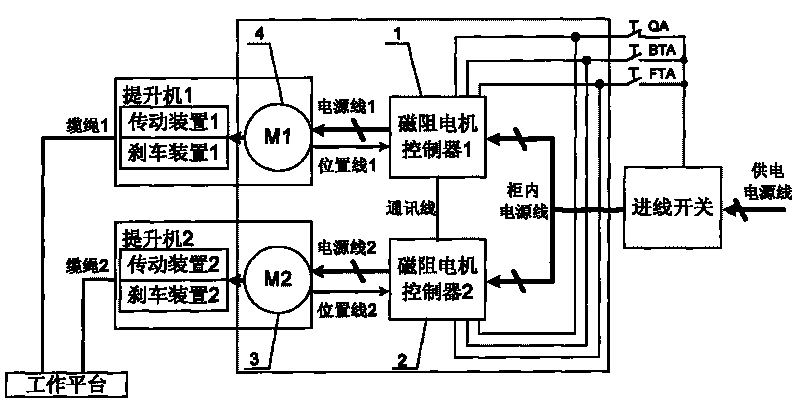

[0020] Such as figure 1 Shown is an electrical system for improving the balance of the electric hanging platform working platform, which is characterized in that: the electrical system includes left and right hanging basket hoists with the same structure and first and second reluctance motor controllers 1, 2 and Up switch BTA, down switch FTA and stop switch QA, wherein the left basket hoist adopts the left switched reluctance motor 4 with a transmission device and a brake device, and the left switched reluctance motor 4 passes through the position line, the power line and the first magnet The first and second reluctance motor controllers are connected through a communication line; The reluctance motor controllers 1 and 2 supply power, and the ascending switch BTA, descending switch FTA and stop switch QA are respectively connected to the digi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com