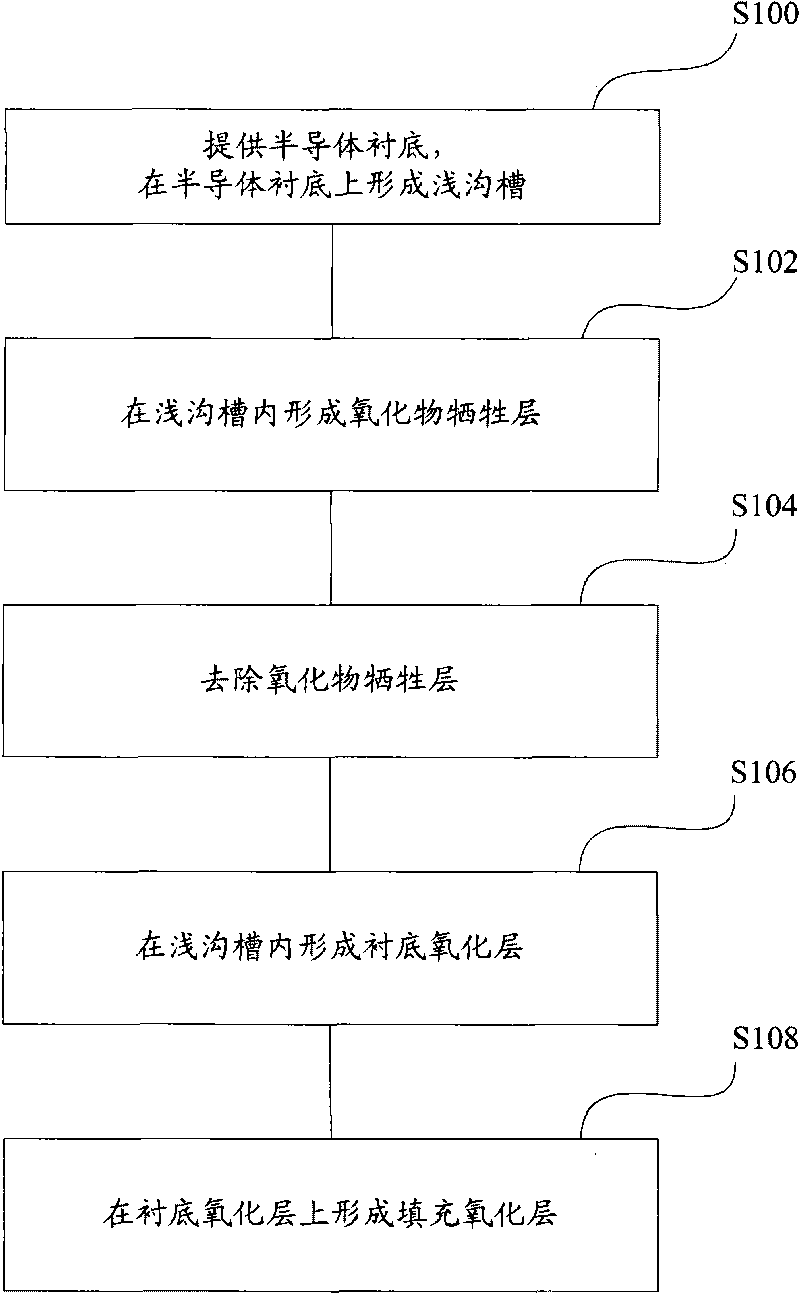

Manufacturing method of shallow trench structure

A fabrication method and shallow trench technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as damage to silicon substrates, degradation of semiconductor device quality, thinning of film thickness, etc., to improve the stress environment , improve the electrical performance, avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

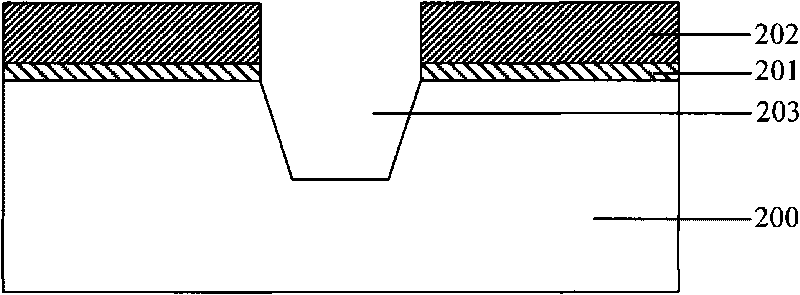

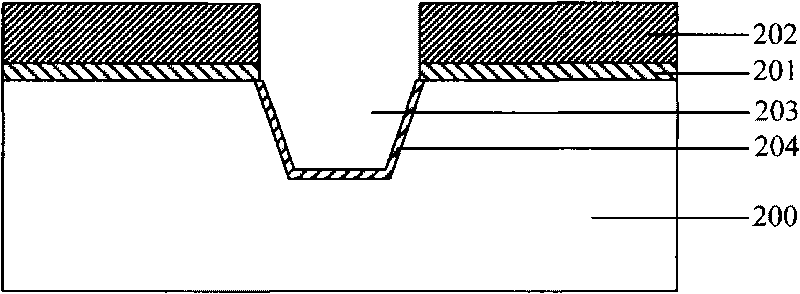

[0019] The inventors found that when making the shallow trench structure, the corners of the shallow trench are sharp, and when the filling oxide layer is formed by the HDP-CVD process, because HDP has a certain etching ability, the plasma oxidizes the substrate. The substrate oxide layer is bombarded, and the thickness of the substrate oxide layer is small, especially the substrate oxide layer at each corner of the shallow trench is also sharp, so the substrate oxide layer is very easy to be destroyed under plasma bombardment, resulting in filling oxidation. The layer is directly in contact with the silicon substrate in the shallow trench, so that the stress in the shallow trench changes, and even destroys the lattice in the shallow trench, causing defects in the lattice, resulting in a decrease in the electrical performance of the semiconductor device.

[0020] Therefore, in the manufacture of semiconductor devices, in order to prevent the above-mentioned defects from affecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com