Single-efficiency absorption type refrigerating device with expander-compressor

An expansion compressor, absorption refrigeration technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of inability to produce cold capacity and low performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

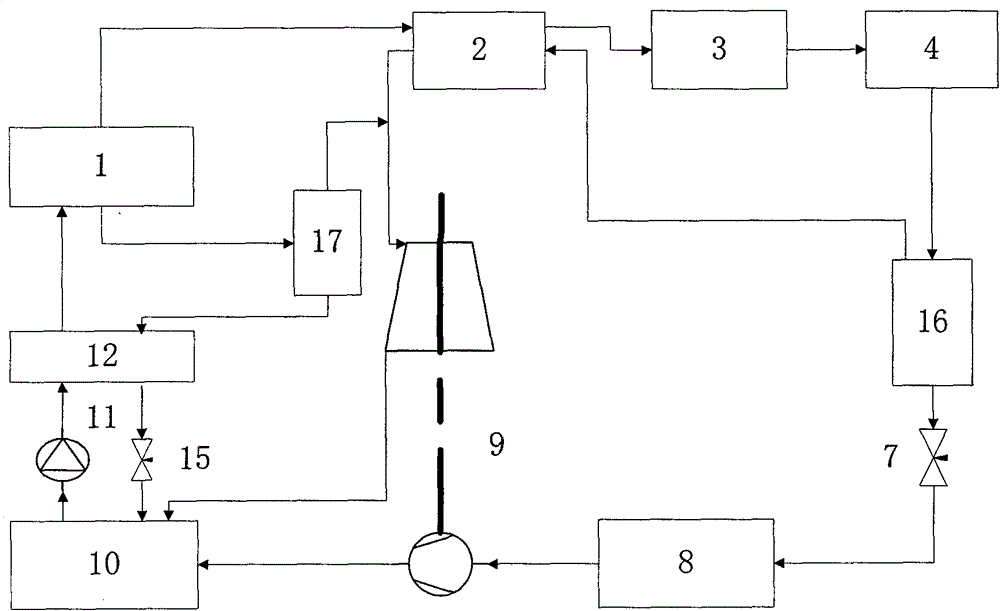

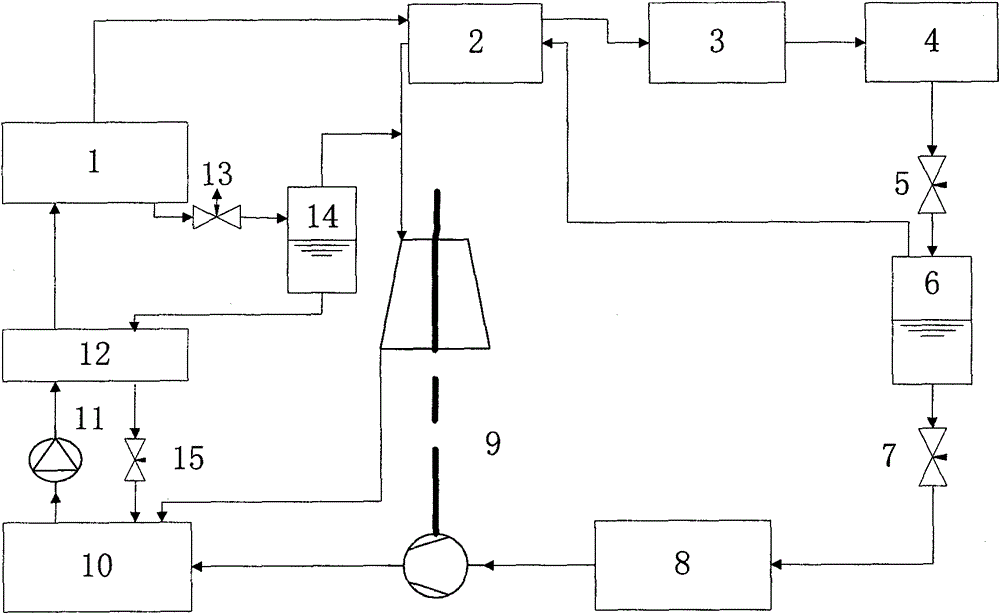

[0010] Such as figure 1 As shown, the single-effect absorption refrigeration unit with expansion compressor includes generator 1, preheater 2, rectifier 3, condenser 4, second throttle valve 7, evaporator 8, expansion compressor 9, absorption Device 10, solution pump 11, solution heat exchanger 12, fourth throttle valve 15, first intermediate heat exchange component 16, second intermediate heat exchange component 17; generator 1, preheater 2, rectifier 3, The condenser 4, the first intermediate heat exchange component 16, the second throttle valve 7, the evaporator 8, the expansion compressor 9, the absorber 10, the solution pump 11, and the solution heat exchanger 12 are connected in sequence, the generator 1, the second The two intermediate heat exchange parts 17, the solution heat exchanger 12, the fourth throttle valve 15, and the absorber 10 are connected in sequence, and the gas phase outlet of the first intermediate heat exchange part 16 is connected to the preheater 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com