Blowing mechanisms of knitting circular weft knitting machine

A technology of circular knitting machine and electric fan, which is applied in the directions of knitting, textile and paper making, etc., to achieve the effect of good blowing effect, concentrated blowing airflow and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

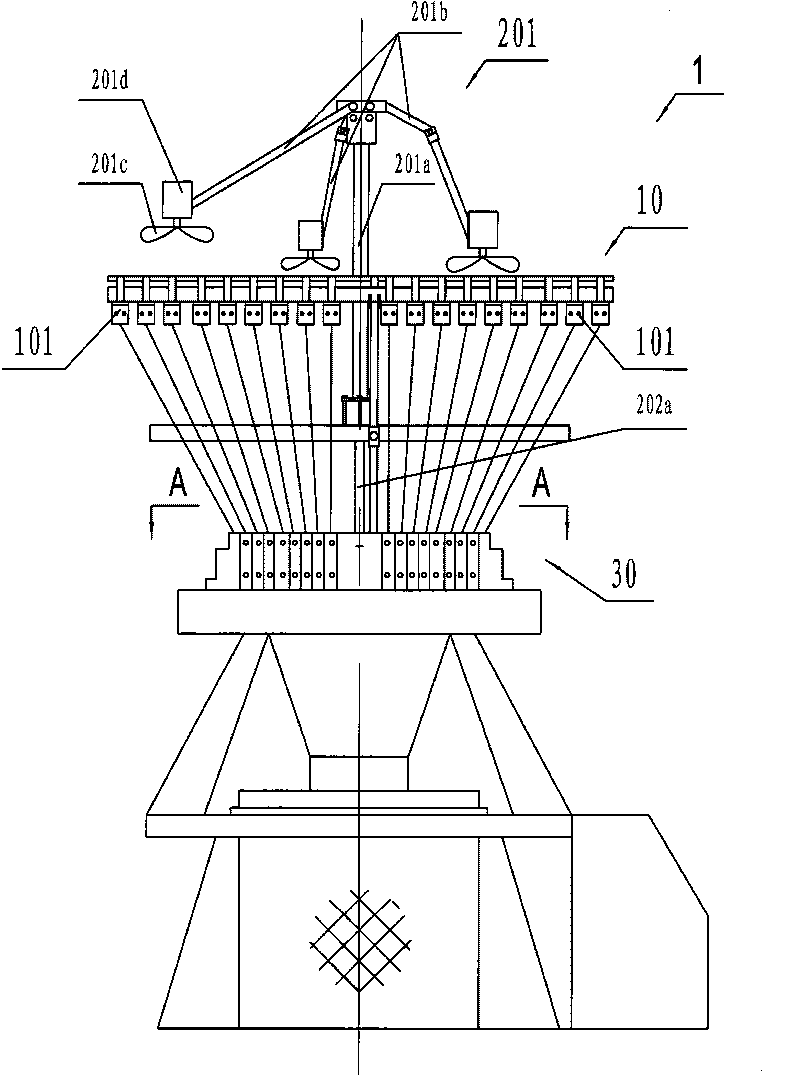

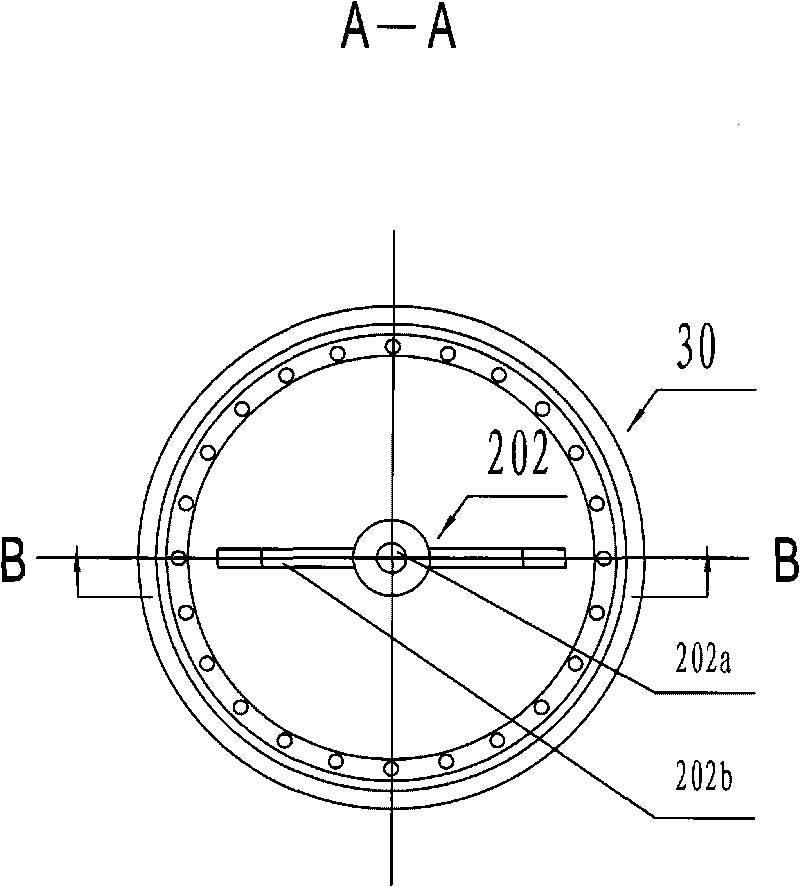

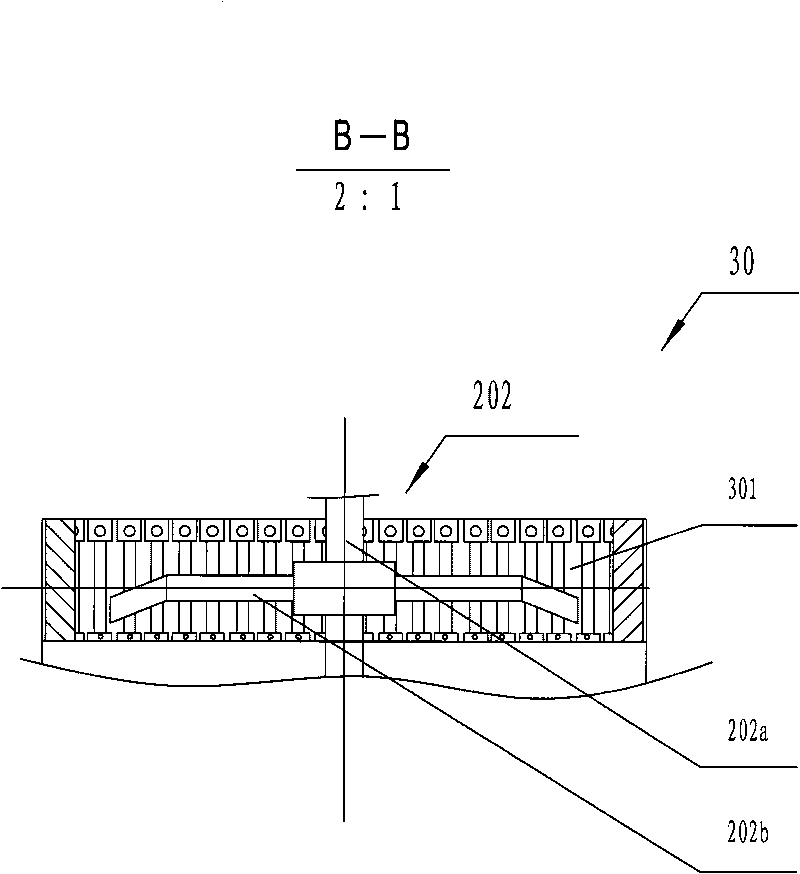

[0015] figure 1 It is a structural schematic diagram of the circular knitting machine of the present invention. As shown in the figure, the circular knitting machine 1 includes a yarn feeding device 10, a blowing mechanism and a yarn guide disc 30. The blowing mechanism includes two sets of blowing mechanisms, namely an upper set of blowing mechanisms 201 and a lower set of blowing mechanisms 202. The yarn feeding device 10 is used as the yarn feeding device of the circular knitting machine 1, and it is mainly composed of a plurality of yarn feeding devices 101 located on the top of the circular knitting machine 1 and distributed around the circumference.

[0016] The upper set of blowing mechanism 201 includes a rotating rod 201a, a bracket 201b, an electric fan 201c, an electric fan driving source 201d, and a rotating rod driving source (not shown in the figure). The center portion of the yarn feeding device 10 is provided with a rotating rod 201a, one end of the support 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com