New process for SG3 type PVC (polyvinyl chloride) resin production

A PVC resin and new process technology, applied in the new process field of SG3 type PVC resin production, can solve the problems of low production efficiency and long polymerization reaction time, and achieve the effects of improving production capacity, good economic benefits and power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

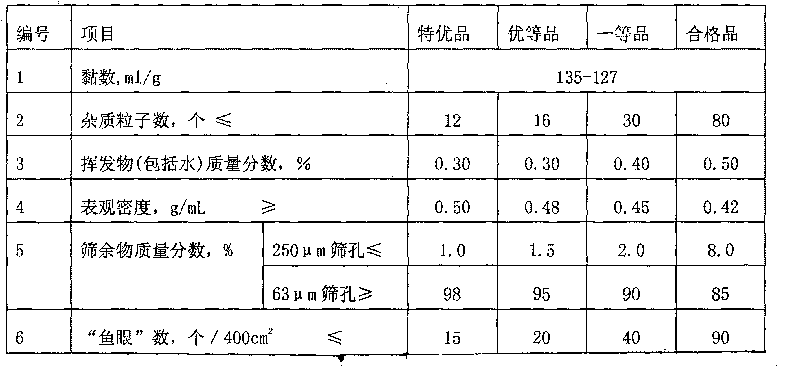

[0017] at 70m 3 Add 22t vinyl chloride monomer, 33t pure water, 350Kg dispersant 1, 140Kg dispersant 2, 120Kg initiator, 4.4Kg chain extender diallyl maleate, 10Kg fatty acid zinc heat stabilizer and 35Kg KZ heat-resistant terminator; dispersant 1 is polyvinyl alcohol aqueous solution with alcoholysis degree of 88%, mass concentration 6%; dispersant 2: hydroxypropyl methylcellulose aqueous solution, referred to as HPMC, mass concentration 4%; initiator It is an aqueous solution of bis(2-ethylhexyl) peroxydicarbonate, referred to as EHP, with a mass concentration of 10%. The polymerization reaction temperature is 55-56° C., and the reaction time is 5.5 hours. The produced PVC resin product has reached the excellent product index in Table 2 (quality grade specification table of SG3 type PVC resin).

Embodiment 2

[0019] at 70m 3 Add 24t vinyl chloride monomer, 32t pure water, 382Kg dispersant 1, 153Kg dispersant 2, 125Kg initiator, 4.8Kg chain extender diallyl maleate, 10Kg fatty acid zinc thermal stabilizer and 35KgKZ heat-resistant terminator; dispersant 1 is polyvinyl alcohol with alcoholysis degree of 88%, concentration 4%; dispersant 2: hydroxypropyl methylcellulose, referred to as HPMC, concentration 3%; initiator is peroxydicarbonic acid Bis(2-ethylhexyl ester), referred to as EHP, the concentration is 8%. The polymerization reaction temperature is 56-58°C, the reaction time is 5.3 hours, and the produced PVC resin product has reached the index of superior products.

Embodiment 3

[0021] at 70m 3 Add 24t vinyl chloride monomer, 31.5t pure water, 360Kg dispersant 1, 150Kg dispersant 2, 130Kg initiator, 5.1Kg chain extender diallyl maleate, 5Kg fatty acid zinc heat stabilizer into the reaction kettle And 35KgKZ heat-resistant terminator; Dispersant 1 is polyvinyl alcohol with alcoholysis degree of 88%, concentration 8%; Dispersant 2: hydroxypropyl methylcellulose, referred to as HPMC, concentration 6%; Initiator is diperoxide Bis(2-ethylhexyl)carbonate, referred to as EHP, has a concentration of 12%. The polymerization reaction temperature is 54-55° C., and the reaction time is 5.8 hours. The produced PVC resin product has reached the index of superior products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com