Process for producing twice sintered humidifying wall ornamentation brick

A technology of secondary firing and production process, which is applied in the field of production technology of secondary firing humidity-controlling wall decoration tiles, can solve problems such as pollution and inconvenient construction, and achieve the effects of increasing deodorization and high-temperature viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

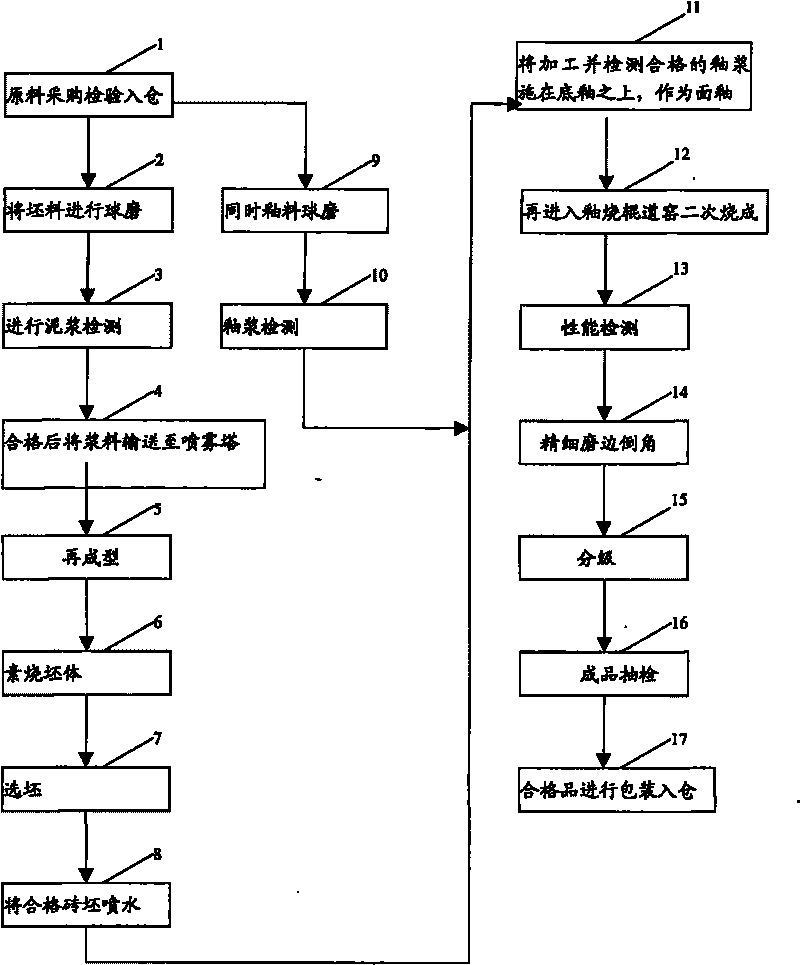

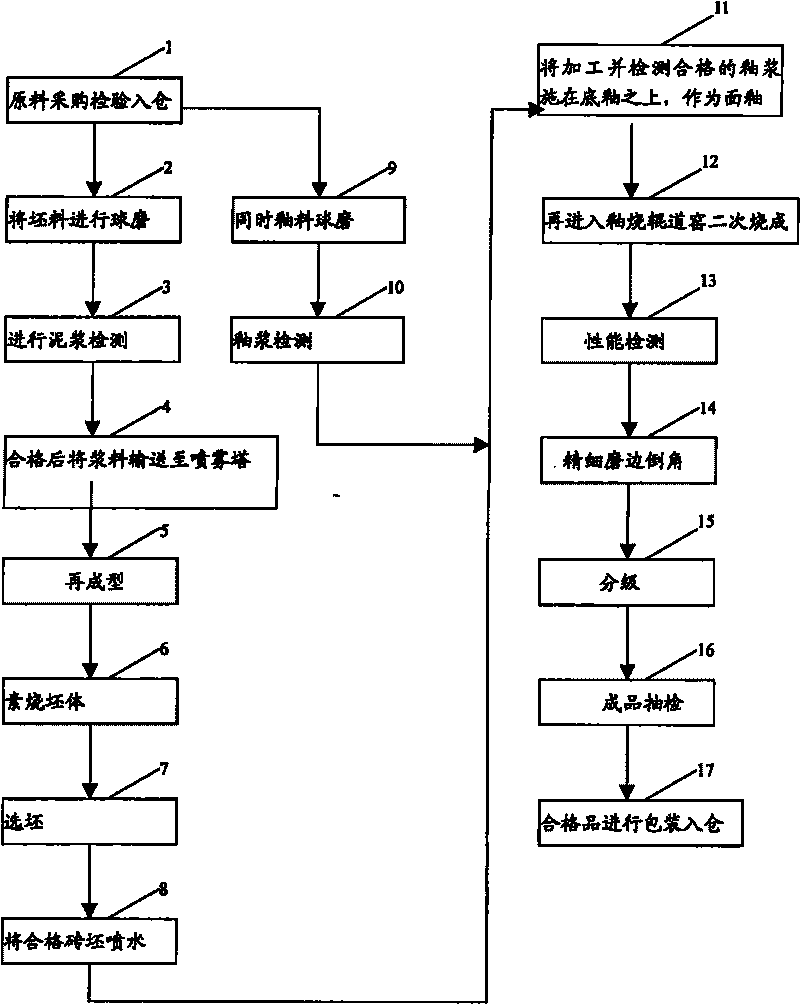

Method used

Image

Examples

Embodiment Construction

[0018] The chemical composition of the base glaze formula:

[0019] Table 1 green body formula chemical composition (wt%)

[0020] ingredients

SiO 2

Al 2 o 3

Fe 2 o 3

TiO 2

CaO

MgO

K 2 o

Na 2 o

burning

Proportion

67.59

16.85

0.84

0.33

4.38

0.35

1.75

0.83

7.08

[0021] Table 2 Glaze formula chemical composition (wt%)

[0022] ingredients

SiO 2

Al 2 o 3

Fe 2 o 3

TiO 2

CaO

MgO

K 2 o

Na 2 o

burning

Proportion

60.46

10.04

0.62

15.81

7.89

0.41

2.95

1.50

0.32

[0023] The green body is formed by dry pressing, the forming pressure is 24bar, the firing process is bisque firing and glaze firing, the highest temperature of bisque firing is 1180°C, and the glaze firing temperature is 1125°C.

[0024] The present invention will be further described bel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com