Method for forming internal threads of composite material

A composite material and molding method technology, which is applied to threaded products, other household appliances, household appliances, etc., can solve the problem of affecting the strength and sealing performance of the threaded part, affecting the strength of the composite pipe connection, missing teeth of the thread and inconsistent tooth shape. Complete problems such as reducing mechanical damage, increasing strength, and reducing the generation of voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

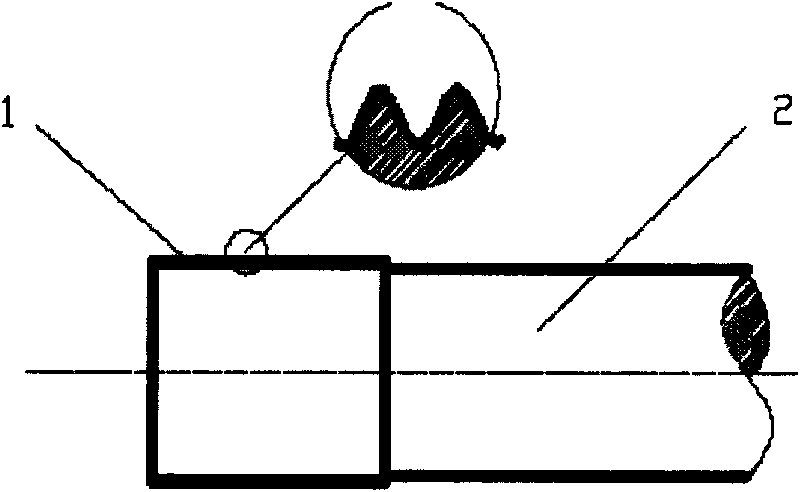

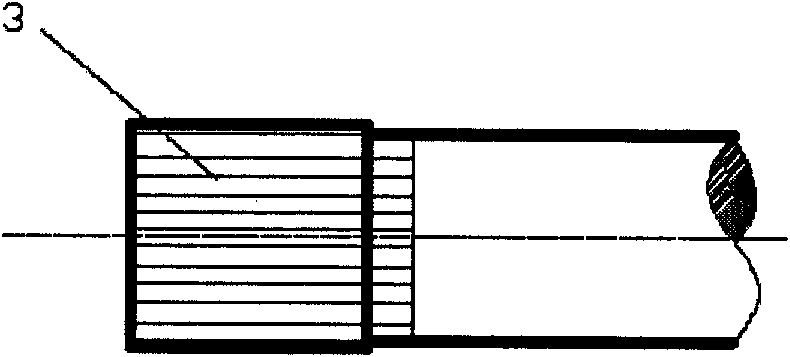

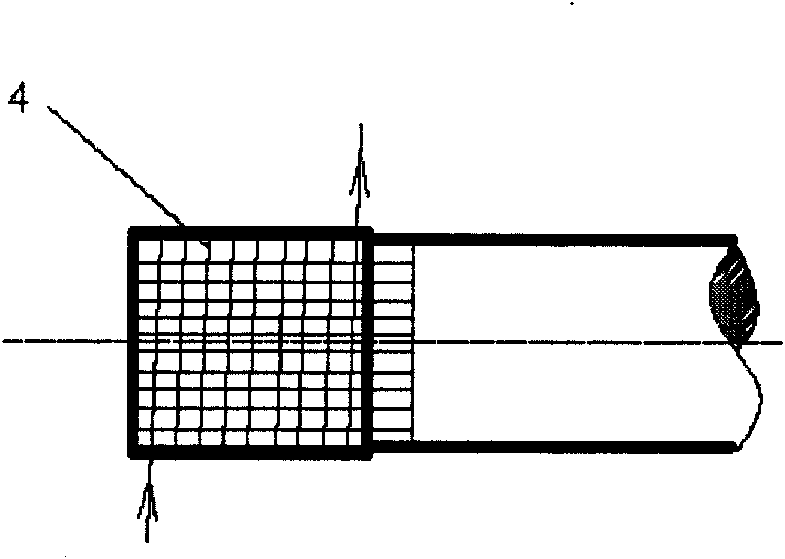

[0019] Molding methods such as figure 1 , 2 , 3, and 4 show that the fiber distribution of the thread teeth after forming is as follows Figure 5 shown.

[0020] (1) First apply a release agent on the mandrel, then wrap the resin-impregnated non-woven fabric circumferentially on the surface of the threaded part 1 of the mandrel, in order to ensure the appearance of the outer contour 6 of the threaded teeth;

[0021] (2) Coating the resin matrix 7 mixed with the whiskers 8 of inorganic materials on the circumferentially wound non-woven fabric layer, the height of the resin should not be lower than the crest of the thread of the mold;

[0022] (3) Lay the reinforced unidirectional fiber cloth 3 on the surface of the mandrel threaded part 1 and the mandrel body part 2 along the ring direction, wherein the fiber direction of the reinforced unidirectional fiber cloth 3 is consistent with the radial direction of the mandrel, and the thickness of the fiber cloth is according to Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com