Method for manufacturing steel pattern plate of taper-end concrete pier

A manufacturing method and technology of steel formwork, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of low accuracy of large steel molds, and achieve construction quality and speed, fast mold erection, and good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings.

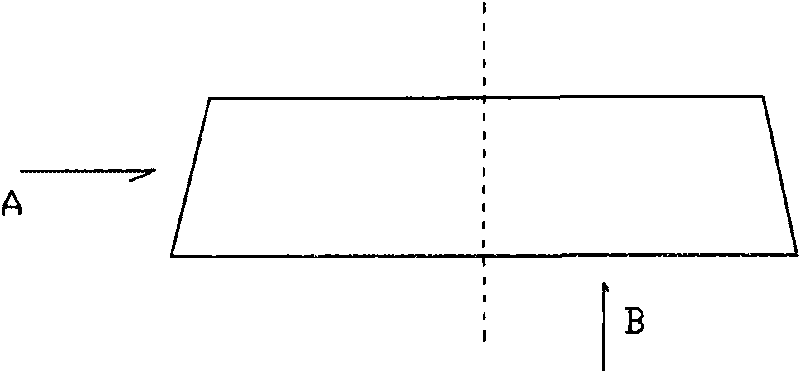

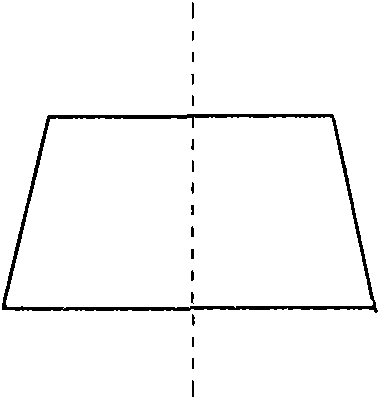

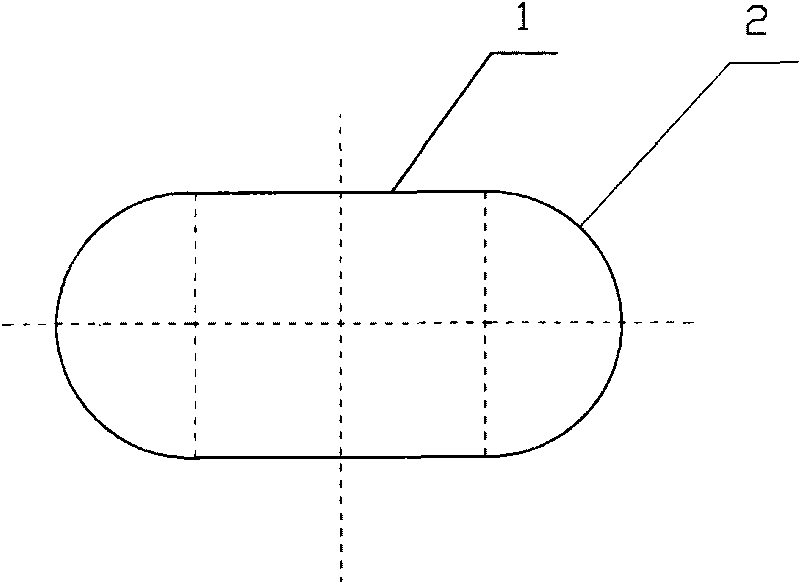

[0021] Referring to the accompanying drawings, a method for manufacturing a steel formwork for a conical end concrete bridge pier of the present invention is directed to a formwork used for a bridge pier with a super-large size and conical ends at both ends. Figure 1-3 Shown is a segmented formwork for the pier, which looks like figure 1 , figure 2 The pyramidal structure is shown. combine image 3 As shown, both ends of the pier are conical structures. The steel formwork used for pouring the integral bridge pier is composed of several segmented formwork, and the height of each segmented formwork is determined by the given steel coil material width. structure as Figure 1-3 As shown, the middle section of the template is composed of a rectangular plate, and the two ends of the template are half (1 / 2) conical ends. For the convenience of production, each end is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com