Hydraulic bearing mounting/dismounting machine

A technology of hydraulic bearing and disassembly machine, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient disassembly, high labor intensity, unsafety, etc., to facilitate storage and transportation, and improve labor efficiency. , the effect of lightweight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

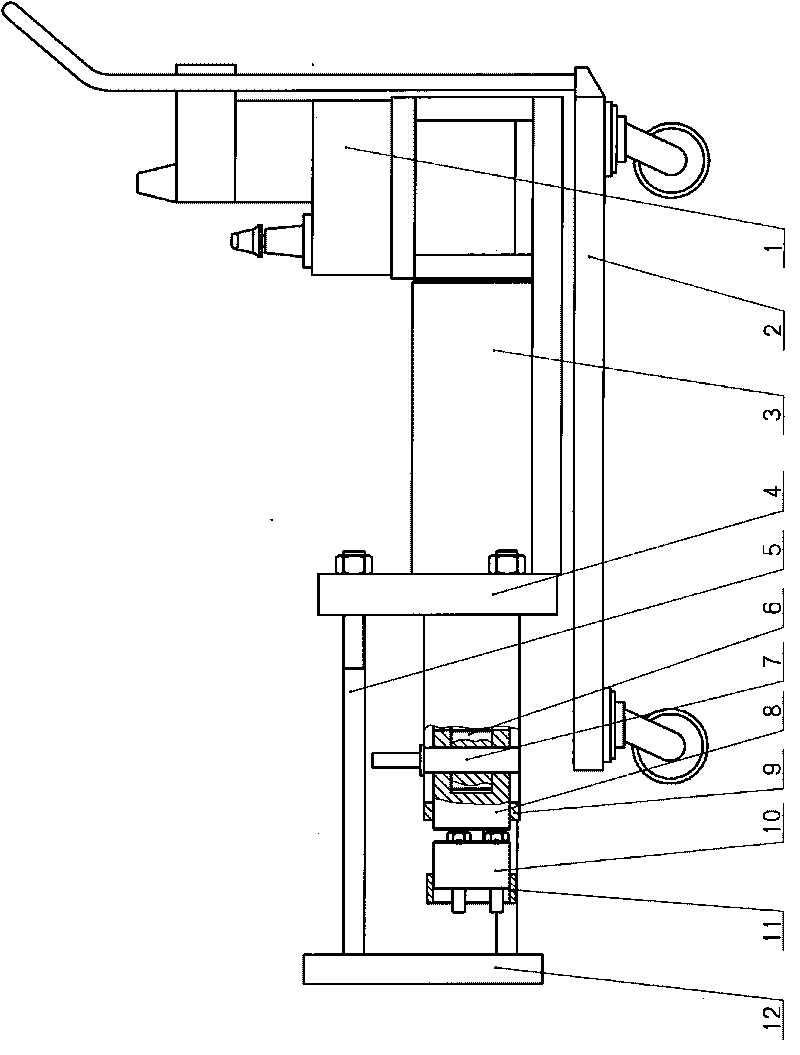

[0015] What accompanying drawing shows is the structural representation of the present invention. The assembly and disassembly bearing device shown in this embodiment consists of a hydraulic pump 1, a trolley 2, an oil cylinder 3, an oil cylinder connecting plate 4, a connecting bolt 5, a piston connecting rod 6, a threading pin 7, a shaft plug connector 8, a support sleeve 9, and an axle The connecting piece 10, the centering ring 11, and the bearing removal plate 12 are composed.

[0016] Wherein, the axle plug connector 8 and the axle connector 10 are connected by an internal thread, the axle plug connector 8 is connected with the piston connecting rod 6 through a pin 7 , and the support sleeve 9 is sleeved on the axle plug connector 8 . The hydraulic pump 1, the oil cylinder 3, the oil cylinder connection plate 4, the shaft plug connector 8, etc. are fixed on the trolley 2.

[0017] When disassembling the bearing, screw the axle connector 10 on the axle to be dismantled f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com