Pipe-flange automatic welding equipment

An automatic welding and equipment technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of pipe out-of-roundness, fluctuation, affecting welding construction and welding quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the drawings and embodiments.

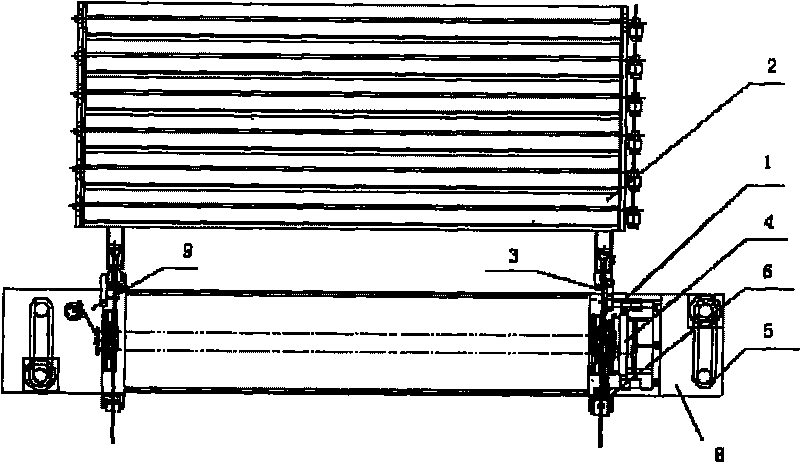

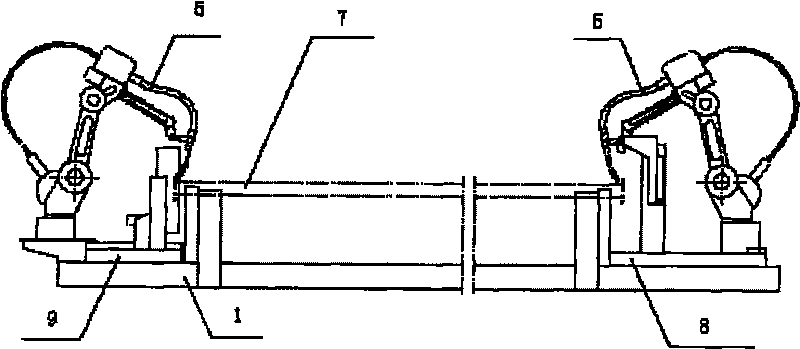

[0017] The present invention is a pipe-flange automatic welding equipment, including a frame 1, which is characterized in that the frame is provided with a material rack conveying device 2, and the frame is provided with a feeding positioning device 3, a clamping rotation device 4, and a discharging device 6. A welding device 5 is also provided on the frame, and the position of the welding device 5 matches the position of the clamping rotating device 4. The rack conveying device 2, the feeding positioning device 3, the clamping rotation device 4, and the unloading device 6 are arranged in sequence from the input to the output of the flange pipe, and the front and rear position relationship between them is matched with each other to facilitate the flange Transmission of the tube.

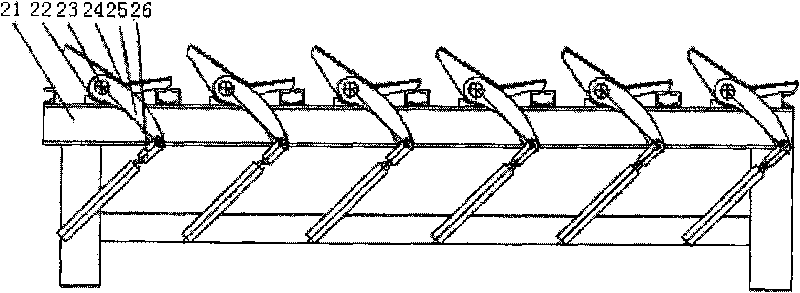

[0018] The material rack conveying device 2 mainly includes 5-8 turning mechanisms, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com