Device for cutting section mould plate

A cutting device and template technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve problems such as inability to accurately cut plates, and achieve the effect of ensuring construction period and quality and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

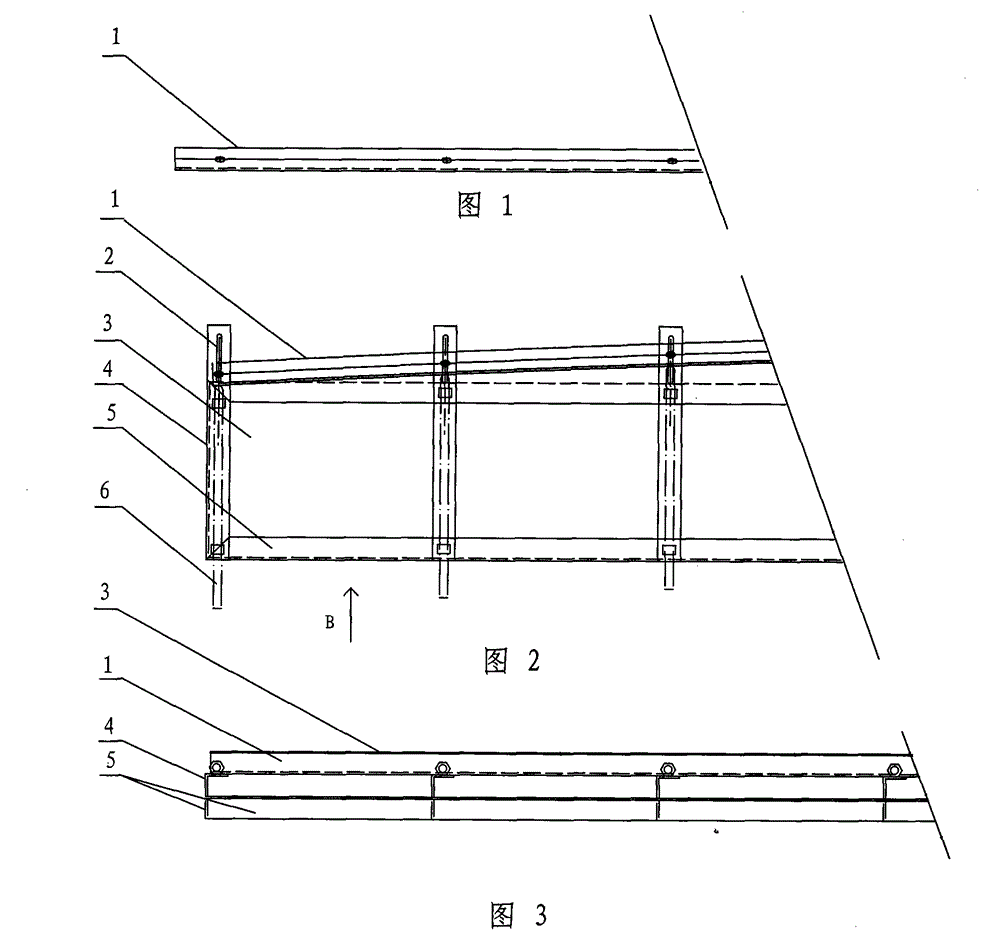

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] refer to Figure 2-3 A type of formwork cutting device of the present invention has a track base 5, which is composed of two parallel angle steels or channel steels, and a steel plate can also be directly used as the track base, and on the track base every 0.5 meters to 1 Fix a leading screw seat 4, this leading screw seat 4 can adopt angle steel or channel steel, leading screw seat and rail base 5 are welded or bolted or adopt other ways to fix. One end of the screw seat 4 is formed with a strip-shaped fixing hole 2, and a fastening bolt is pierced in the hole. There is a fixing hole on the track 1 corresponding to the screw seat 4, and the track 1 is connected to the screw seat 4 by bolts. , the track 1 is made of angle steel or I-beam or other structural materials. The other side of the leading screw seat has an adjusting leading screw 6, and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com