Upper die buffering mechanism of miniature stamping equipment

A technology of stamping equipment and buffer mechanism, which is applied in the field of upper die buffer mechanism, can solve problems such as increased cost, poor coaxiality and motion stability, and affects sliding fit accuracy, and achieves the effects of avoiding breakage, high stability, and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

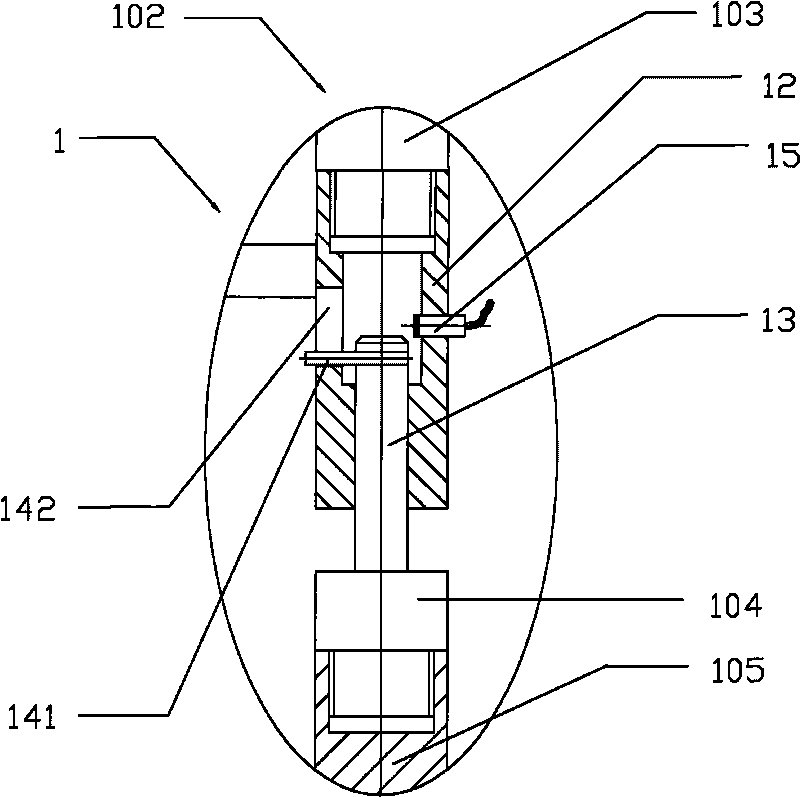

Image

Examples

Embodiment 1

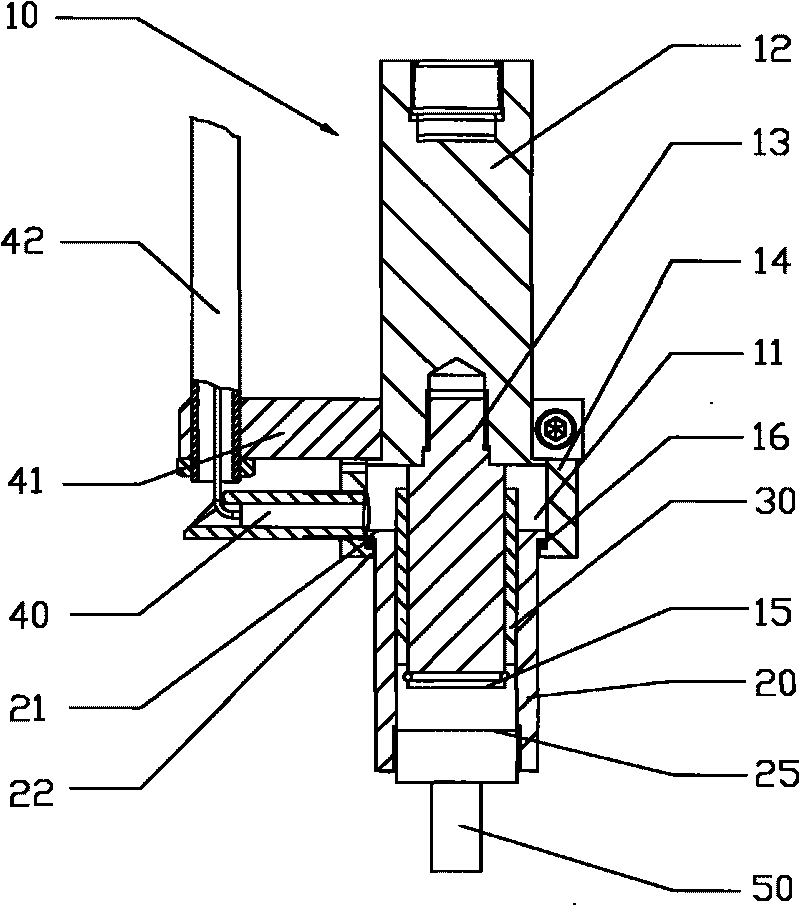

[0026] As attached figure 2 As shown, the upper mold buffer mechanism in this embodiment includes:

[0027] The working piston 10 is composed of a piston rod 12 and a connecting shaft 13 fixedly connected to each other. The piston rod 12 and the connecting shaft 13 are connected by threads. The working piston also has an annular wall 14 which is connected to the piston rod 12 Coaxial, and the upper end is fixedly connected with the piston rod 12;

[0028] A sliding sleeve 20 sleeved outside the connecting shaft 13 is sandwiched between the annular wall 14 and the piston rod 12, and the upper mold 50 is fixedly installed at the lower end of the sliding sleeve 20.

[0029] At the upper end of the sliding sleeve 20, a ring-shaped boss 21 is protruding outward in the radial direction; at the lower end of the ring-shaped wall 14 there is a ring-shaped limiting block 22 protruding inward. The space above the block 22 forms an annular positioning groove 11 coaxial with the working piston ...

Embodiment 2

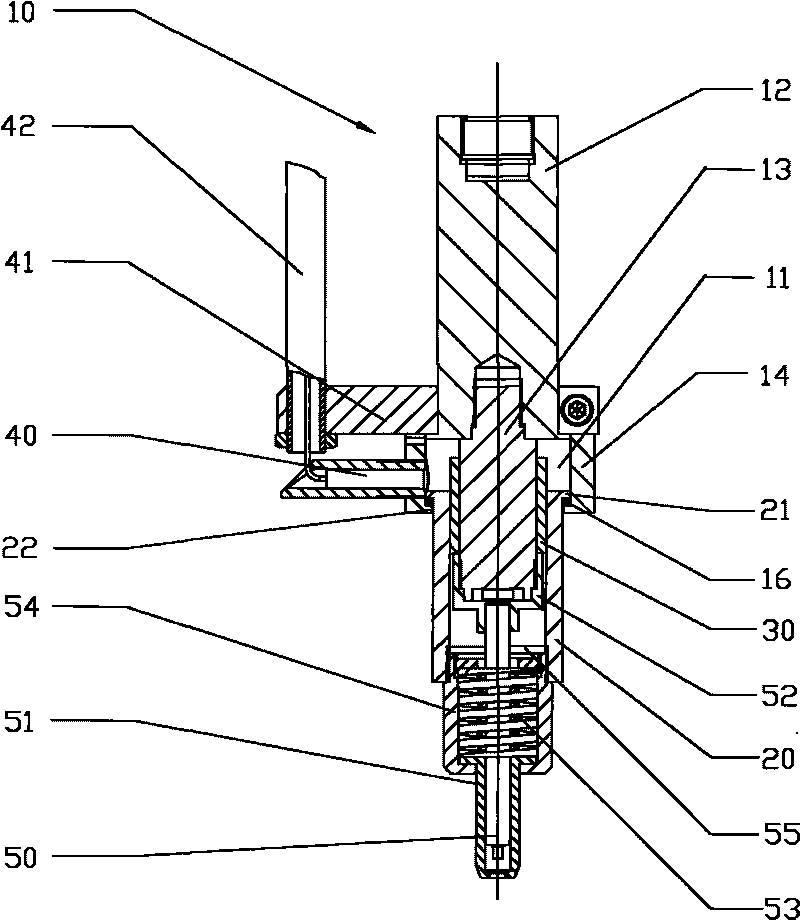

[0036] As attached image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that the upper mold 50 is fixed to the bottom of the connecting shaft 13 by the upper mold fixing sleeve 52. On the outer side of the upper mold 50, a mechanism for assisting demolding is provided. The mechanism includes a spring fixing sleeve 54 corresponding to the downward extension of the sliding sleeve 20, and a demolding spring 53 is clamped in the spring fixing sleeve 54 , The upper mold 50 passes through the center of the ejection spring 53. On the top of the ejection spring 53, a spring base 55 is fixedly provided. A demolding sleeve 51 is nested at the lower end of the spring fixing sleeve 54. The demolding sleeve 51 can slide longitudinally relative to the demolding fixing sleeve 54 so as to push the demolding spring 53 upward.

[0037] When the working piston 10 drives the sliding sleeve 20 to move downwards, once the lower surface of the stripping sleeve 51 touches an obje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com