Production method for pressure-swing adsorption concentration of methane in gas

A technology of pressure swing adsorption and production method, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc. It can solve problems such as application limitations, difficult methane concentration, gas explosion, etc., to improve utilization and utilization rate, expand The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

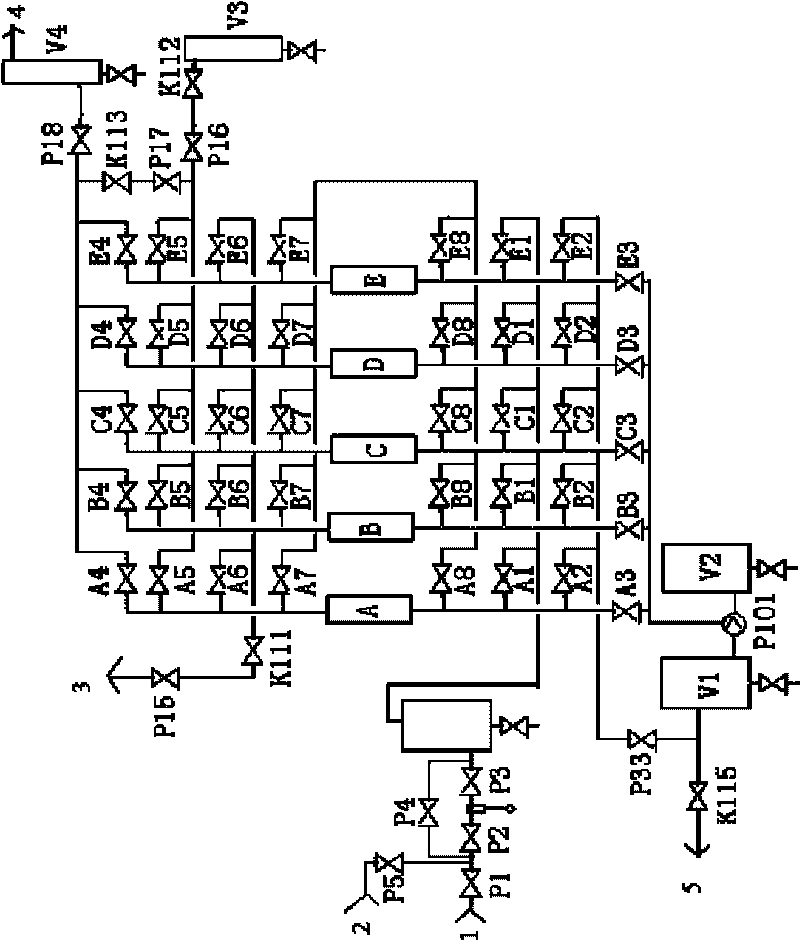

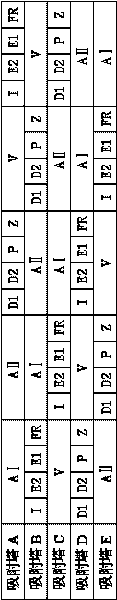

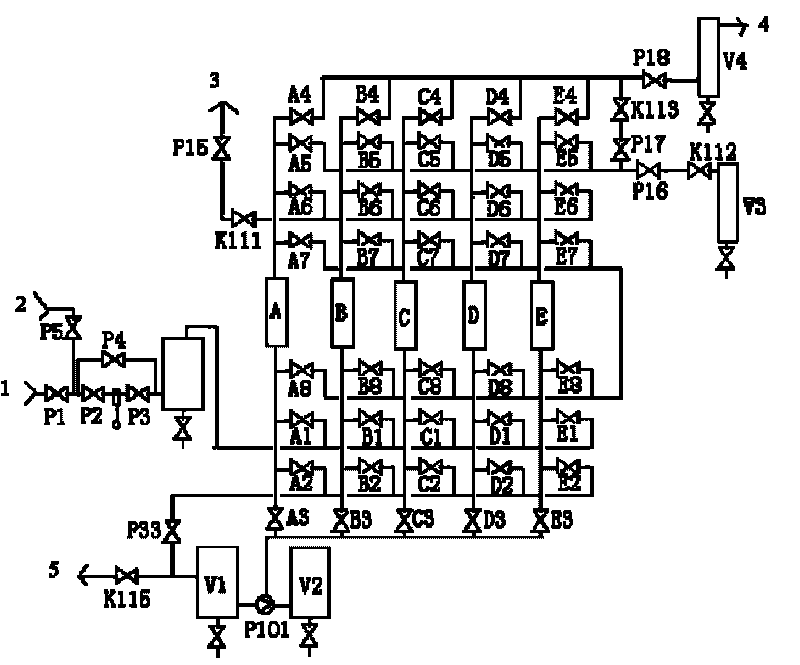

[0029] Pressure swing adsorption devices such as figure 1 As shown, a VPSA process with two towers in series adsorption and two pressure equalizations is adopted. The safety facilities of the pressure swing adsorption unit are realized through the following measures:

[0030] 1. Gas compression uses a screw compressor unit dedicated to gas gas. The main engine in the screw compressor unit dedicated to gas gas adopts a single-stage twin-screw internal water spray cooling structure, and the direction of gas inlet and outlet is two-stage compression.

[0031] 2. The adsorption tower is filled with activated carbon adsorbent.

[0032] 3. Fill the adsorption tower and the buffer tank with aluminum alloy mesh explosion suppression material (FC-1) with 3% of the adsorbent volume.

[0033] 4. The pipeline of the pressure swing adsorption device is filled with aluminum alloy mesh explosion suppression material (FC-1) with 1% of the volume of the pipeline.

[0034] 5. Adopt special p...

Embodiment 2

[0064] The methane content of the coal mine gas in this embodiment is 50%, the adsorption pressure is 1.0 MPa, and the adsorption temperature is 40°C. The pressure swing adsorption device is provided with the safety facilities of Example 1. The adsorption tower is filled with 3% aluminum alloy mesh explosion suppression material (FC-1) of the adsorbent volume, and the pipeline is filled with aluminum alloy mesh explosion suppression material (FC-1) with 1% of the pipeline volume. Then implement according to the processing steps of embodiment 1.

[0065] In this embodiment, gas with a methane content of about 95% can be obtained, and the methane yield is about 99%. The bleed gas and replacement gas discharged from the outlet 3 are recycled, and the methane content of the gas discharged from the outlet 4 is about 0.5v%. System safe, no CO detected, CO 2 Content unchanged.

Embodiment 3

[0067] The methane content of the coal mine gas in this embodiment is 10%, the adsorption pressure is 0.3 MPa, and the adsorption temperature is 40°C. The pressure swing adsorption device adopts the safety facilities of the first embodiment. The adsorption tower is filled with 4% aluminum alloy mesh explosion suppression material (FC-1) of adsorbent volume, and the pipeline is filled with aluminum alloy mesh explosion suppression material (FC-1) with 2% pipeline volume. Then implement according to the processing steps of embodiment 1.

[0068] In this embodiment, gas with a methane content of 65% can be obtained, and the methane yield is about 95%. The bleed gas and replacement gas discharged from the outlet 3 are recycled, and the methane content of the gas discharged from the outlet 4 is about 0.5v%. System safe, no CO detected, CO 2 Content unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com