Strip combined filter plate and filter chamber using same

A filter plate and strip-shaped technology, which is applied in the field of strip-shaped combined filter plate and its applied filter tank, can solve the problems of large water head loss, low water treatment efficiency, large joints of filter plates, etc. The effect of stable sand layer, high water treatment efficiency and small head loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

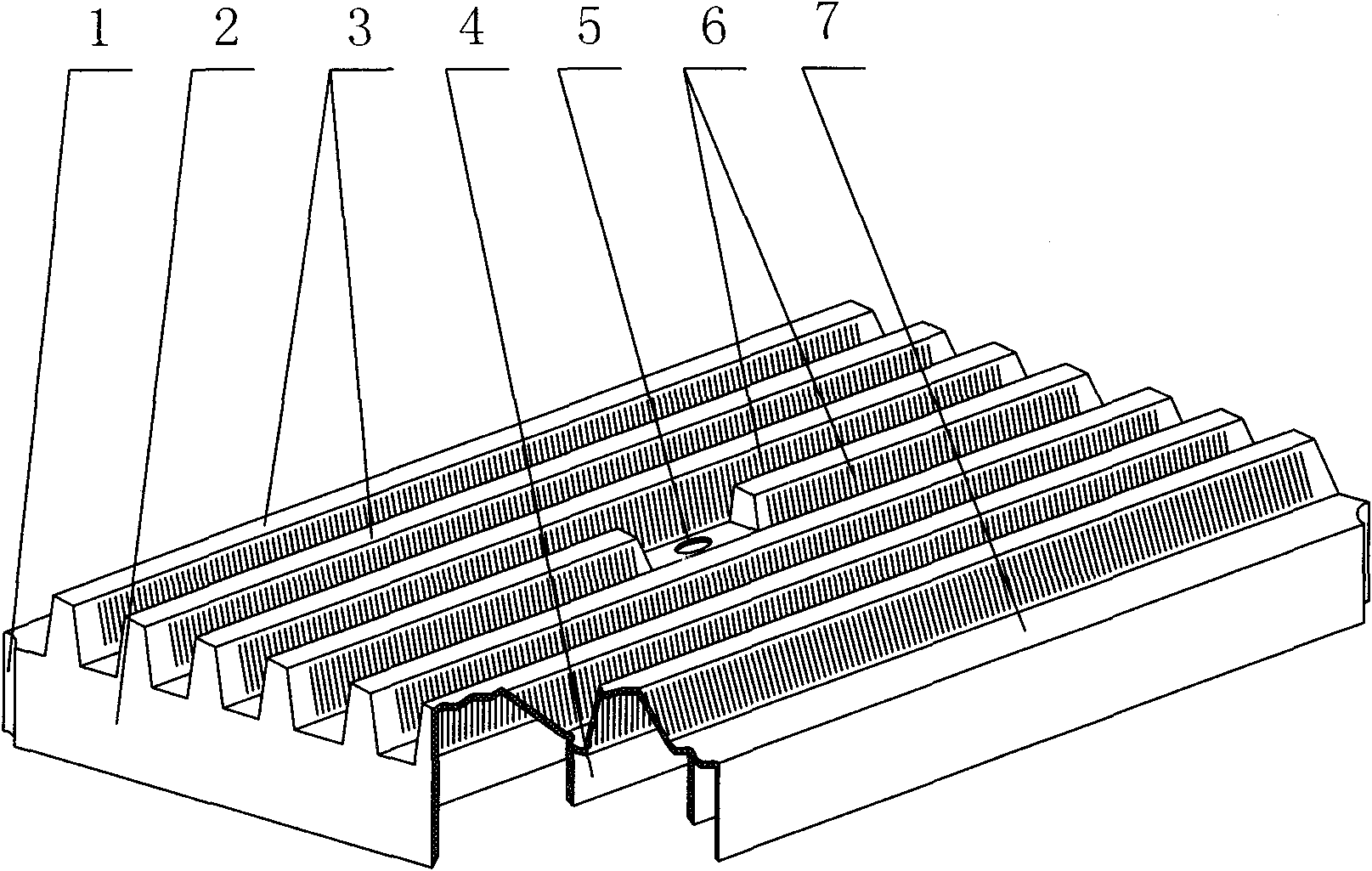

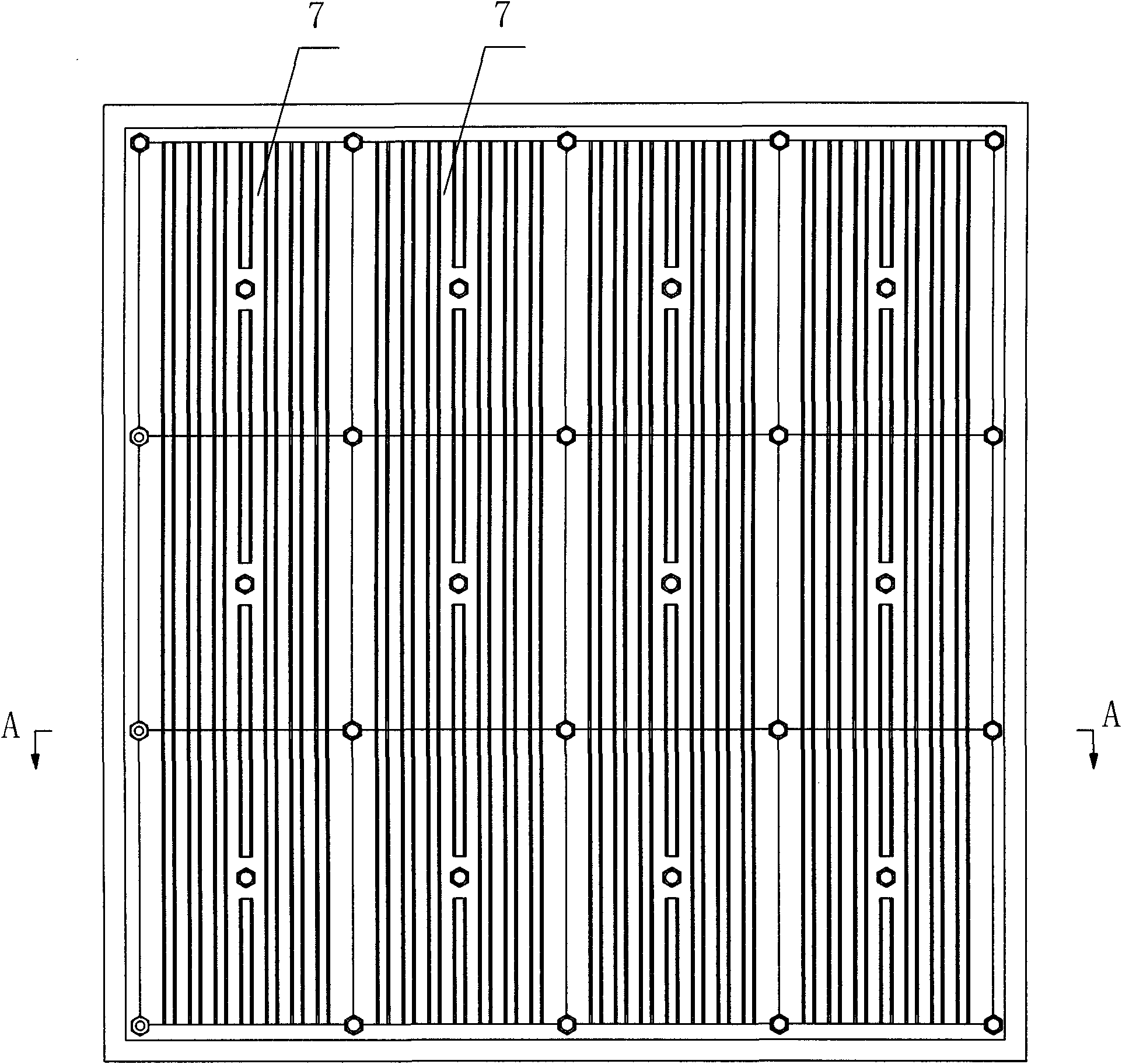

[0020] figure 1 is a perspective view of a preferred embodiment of a strip-shaped combined filter plate. Depend on figure 1 It can be seen that the front of the plate body 7 of the strip-shaped combined filter plate is rectangular, and a surrounding wall 2 is provided around the plate body 7 to enhance the strength of the filter plate. On the water-facing surface of the plate body 7, there are a plurality of elongated raised portions 3 arranged in parallel. The cross-section of the raised portions 3 is preferably trapezoidal, or triangular or arc-shaped (parabolic) or other geometric shapes. The height of the raised portion is preferably 25-40 mm, so as to maintain good strength and good porosity.

[0021] On both side walls of the raised part 3 are evenly distributed filter slits 6, the filter slits are 22-30mm long and 0.3-0.5mm wide, which can maintain a good filtering effect.

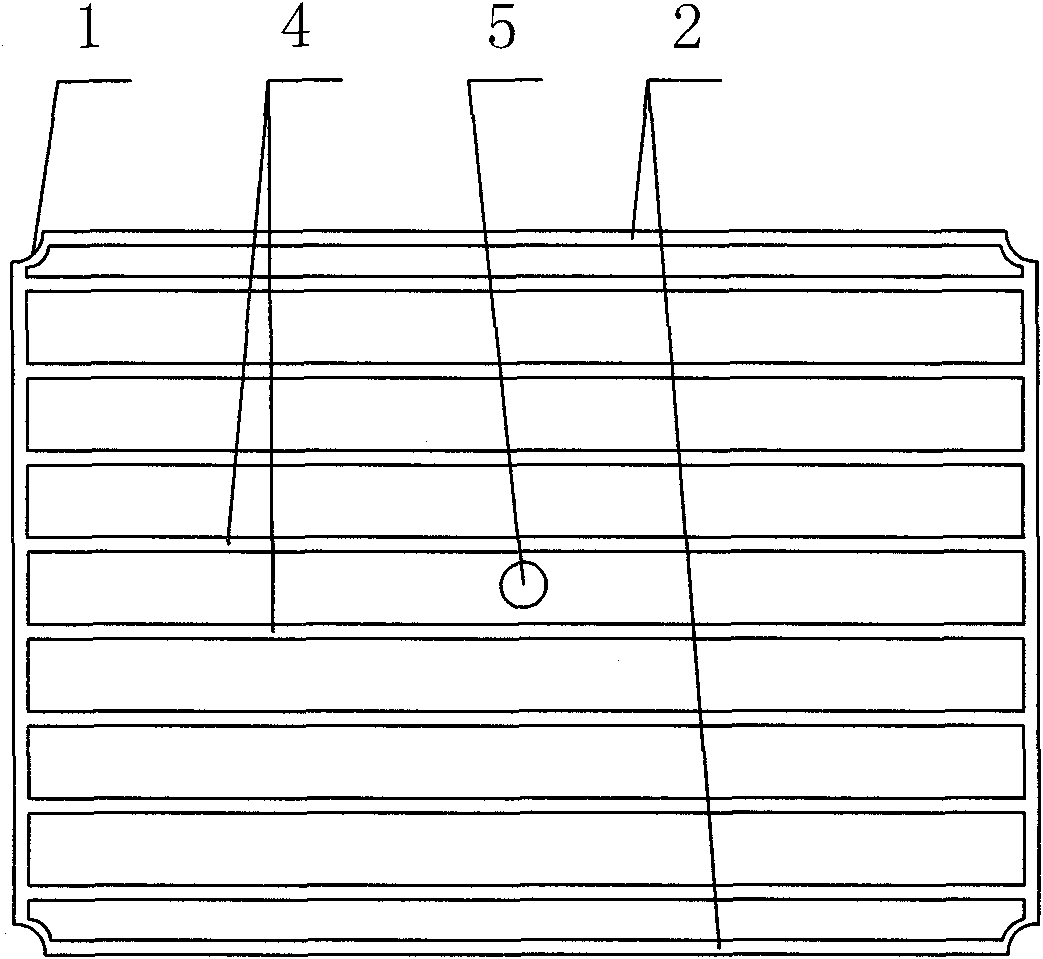

[0022] Depend on figure 2 It can be seen that, in order to further enhance the strength of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com