Composition of aromatic isothiocyanate and allyl isothiocyanate and application thereof

A technology of allyl isothiocyanate and phenylethyl isothiocyanate, which is applied in the application, biocide, animal repellent and other directions to achieve human and animal safety, reduce the amount of use, and improve the control effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

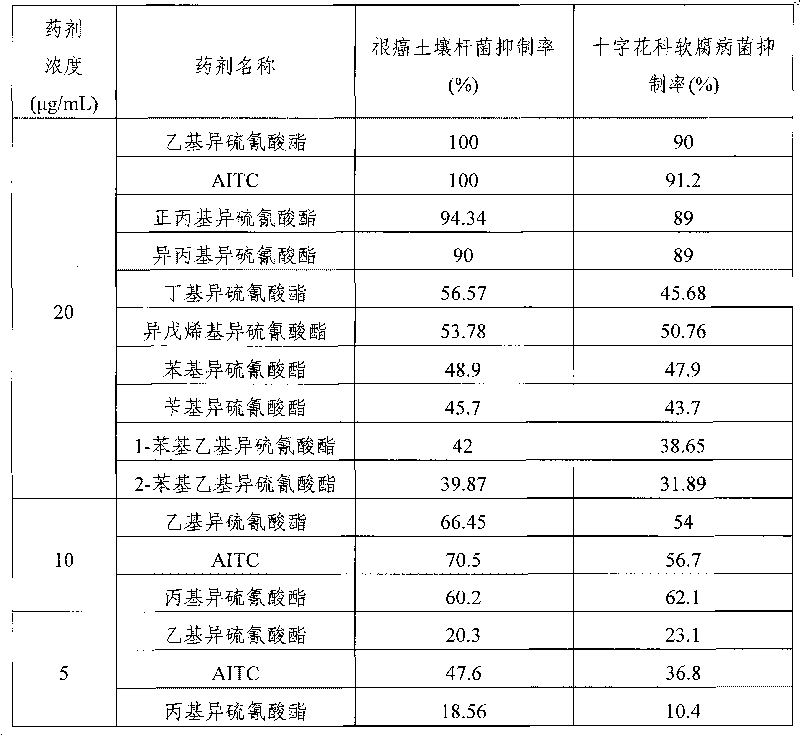

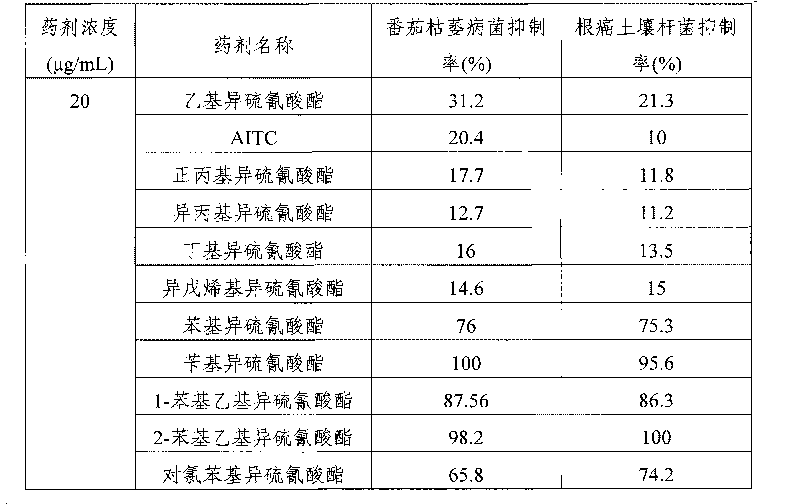

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 The production of 8% AITC and 2% benzyl isothiocyanate (BITC) composition oil

[0056] Accurately and quantitatively weigh the AITC original drug with a content of 94% (note: the contents in the present invention are all percentages by weight) (note: the isothiocyanate original drug and extract in the present invention are from Wuhan Leliji Biotechnology Co., Ltd. Co., Ltd.) 4.25kg, then weighed 25kg of 4% BITC extraction mother liquor, and fully mixed in a 2M3 blending tank. Add 0.5 kg of accurately weighed ascorbic acid, and mix well again. Then accurately drop 10.125kg of ethyl acetate and 10.125kg of vegetable oil into the blending tank, fully mix, and continue to stir for 1 hour. The oil preparation product of 50kg AITC and BITC composition is formulated.

[0057] Sampling analysis showed that the content of AITC in the product was 8.01%, and the content of BITC was 2.00%. The product is divided into aluminum cans coated with barrier material, each ...

Embodiment 2

[0058] Embodiment 2 Production of 11.7% AITC and 1.3% benzyl isothiocyanate composition aqueous emulsion

[0059] Accurately weigh 249kg of AITC with a content of 94%, 28.9kg of benzyl isothiocyanate with a content of 90%, and 20kg of ascorbic acid, and fully stir them evenly in a blending tank. Then quantitatively add 200kg of agricultural emulsifier TX-10, 366kg of ethyl acetate, 350kg of vegetable oil into the blending tank, add 786.1kg of water, stir while adding, after all materials are added, continue to stir with a mixer for 1 hour, and prepare 2 tons of AITC and BITC composition oil products.

[0060] Sampling test results show that the product contains 11.98% of AITC and 1.30% of benzyl isothiocyanate, and finally obtains a composition product with an effective component content of 13.3%. The product is packed in a 500mL glass bottle and the mouth of the bottle is sealed ,put on label.

Embodiment 3

[0061] Example 3 Production of 1% AITC and 6% 2-phenylethyl isothiocyanate composition oil

[0062] Accurately and quantitatively weigh 50kg of AITC extraction mother liquor with a content of 20%, and then weigh 66.7kg of benzyl isothiocyanate with a content of 90%. 3 Mix thoroughly in the mixing tank. Add 30kg of accurately weighed ascorbic acid, and mix well again. Then accurately drop 450kg of ethyl acetate and 450kg of vegetable oil into the blending tank and mix thoroughly. Stirring was continued for 3 hours. The oil preparation product of 1 ton of AITC and BITC composition was formulated.

[0063] Sampling analysis showed that the content of AITC in the product was 1.00%, and the content of BITC was 5.99%. The product is divided into aluminum cans coated with barrier material, 5kg per can, 200 cans in total. The mouth of the jar is sealed, and a label is attached to be a composition oil product with an effective component content of 7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com