Method for making insulated stranded wire

A manufacturing method and stranded wire technology, applied in the direction of insulated conductors, insulated cables, organic insulators, etc., can solve the problems of miniaturization of electronic components, high frequency, low voltage of enameled wire stranded wires, large high-frequency coils, etc., to achieve Reduce leakage inductance and distributed capacitance, reduce volume, and achieve good high-frequency performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in combination with specific embodiments.

[0009] A method for manufacturing insulated stranded wires. The method adopts a Φ3mm copper rod to be thinned by a wire drawing machine and then annealed and painted to make enameled wires. The machine sequentially extrudes two layers of polyester insulating layers on the outside of the enamelled stranded wire, and finally extrudes the polyamide resin insulating layer on the outside of the two layers of polyester extruded insulating layers.

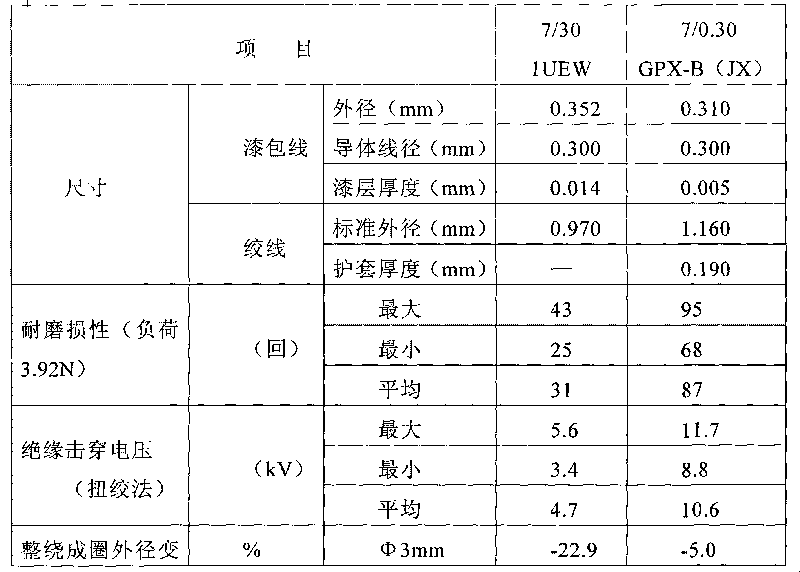

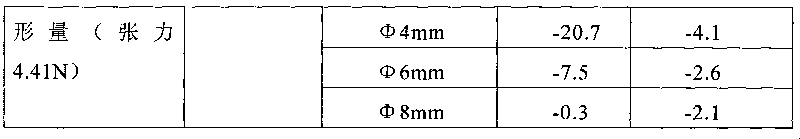

[0010] The performance of the three-layer insulated twisted wire used for high-frequency coil obtained by the present invention:

[0011] 1. Good wear resistance, smooth surface, suitable for high-speed winding;

[0012] 2. It has outstanding voltage resistance performance and can withstand voltage between layers. Using this stranded wire can remove the inner skeleton baffle and isolation layer of the transformer, so that there is no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com