Method for detecting deformation of fuel assembly after irradiation of pressurized-water reactor nuclear power plant and implementation device thereof

A technology for pressurized water reactor nuclear power plants and fuel assemblies, which is applied in nuclear power generation, reactors, nuclear engineering, etc., can solve the problems of inability to measure at close range, inability to use measurement equipment, and low accuracy, and achieve detailed inspection content, short inspection time, The effect of high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The device and method for detecting the deformation size of the fuel assembly of the PWR nuclear power plant of the present invention after irradiation are described below with reference to the accompanying drawings and embodiments:

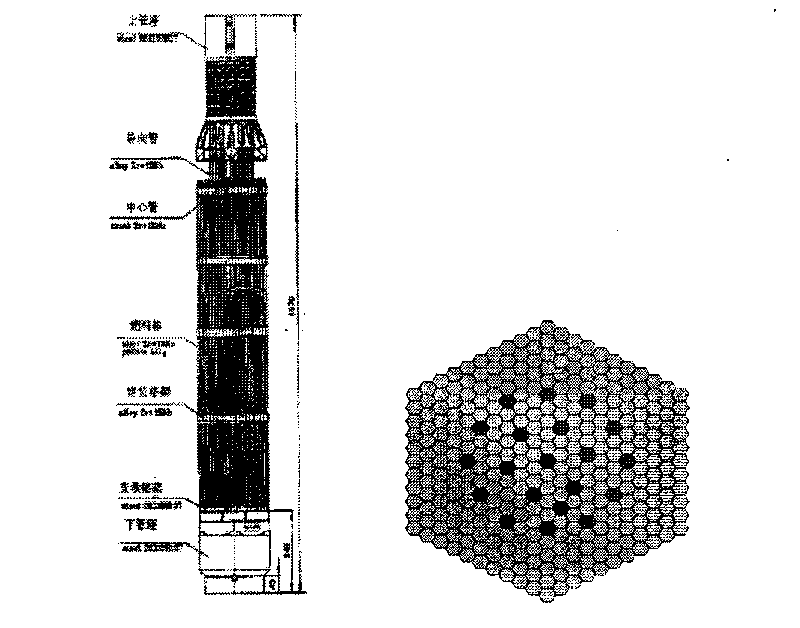

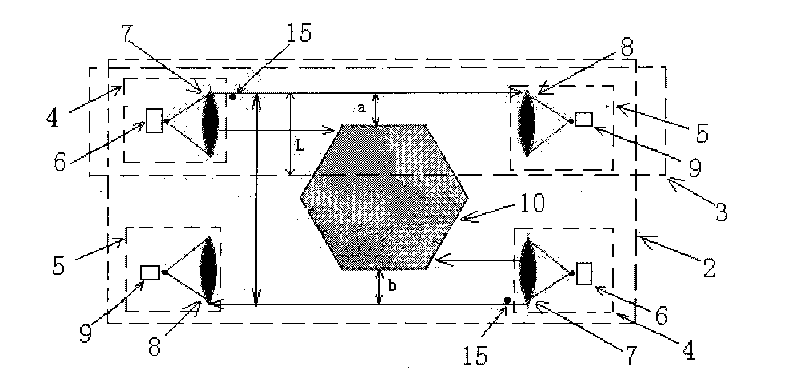

[0031] Such as image 3 As shown, a method for detecting the deformation size of a fuel assembly after irradiation in a PWR nuclear power plant uses a detection group 2 composed of two detection units 3 to measure the width of an opposite side of the fuel assembly 10 and the diameter of the fuel rod and the distance between the fuel rods. According to the shape of the fuel assembly 10, multiple detection groups 2 are arranged to measure the width of each opposite side of the fuel assembly 10 simultaneously.

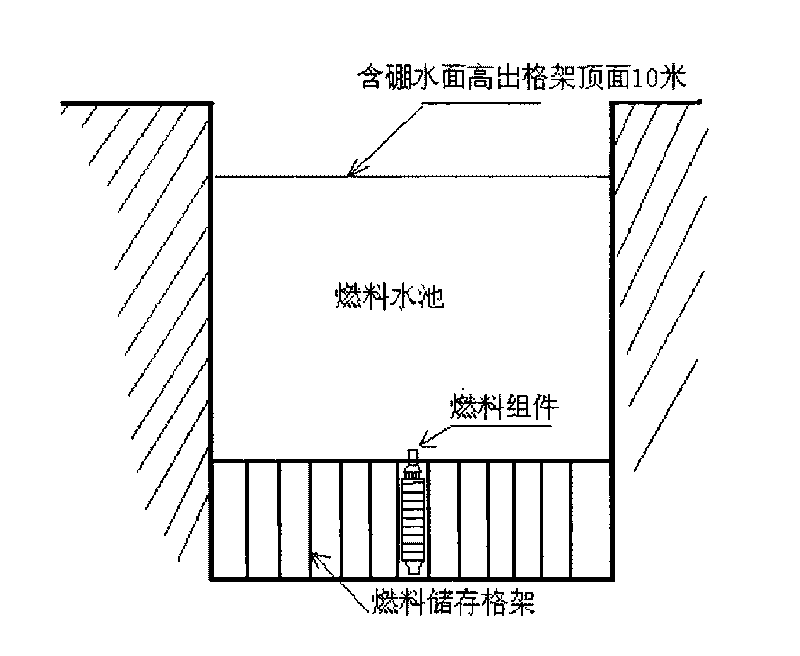

[0032] Such as Figure 4 , Figure 5 As shown, a device for detecting deformation dimensions of fuel assemblies after irradiation in a PWR nuclear power plant includes: an underwater detection part, a control cabinet 12, a positioning came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com