Tester and testing method for winding lead material of transformer

A technology of transformer windings and testing methods, applied in the direction of material impedance, etc., can solve problems such as sharp increase in production costs of transformer products, undetectable detection methods, and difficulties in operating trustworthy enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

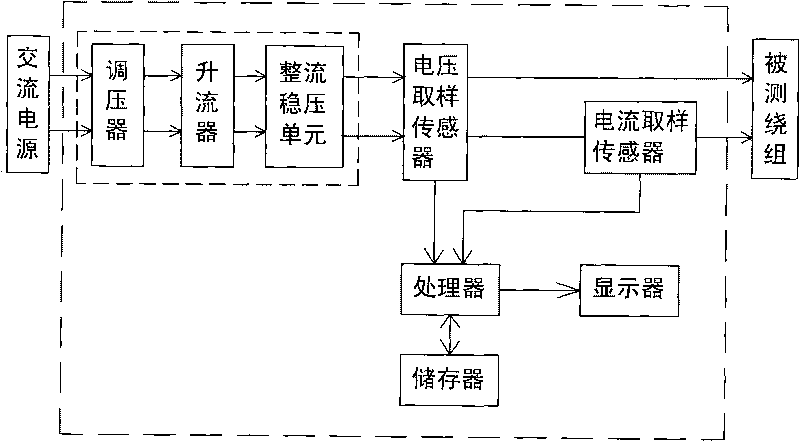

[0020] like figure 1 As shown in the figure, a DC power supply, a processor, a voltage sampling sensor, a current sampling sensor and a display are arranged in the casing, and a connection terminal is arranged outside. The input end of the processor is respectively connected to the voltage sampling sensor and the current sampling sensor, the data end of the processor is connected to the storage, and the output end of the processor is connected to the display. The output end of the DC power supply is connected to the connection terminals arranged outside the casing through wires. The voltage sampling sensor is arranged on both sides of the output end of the DC power supply. The current sampling sensor is arranged on the wire between the DC power supply and the connection terminal. The DC power supply includes a voltage regulator, a booster and a rectifier voltage regulator unit. The input end of the voltage regulator is connected to the AC power supply, the output end of the...

Embodiment 2

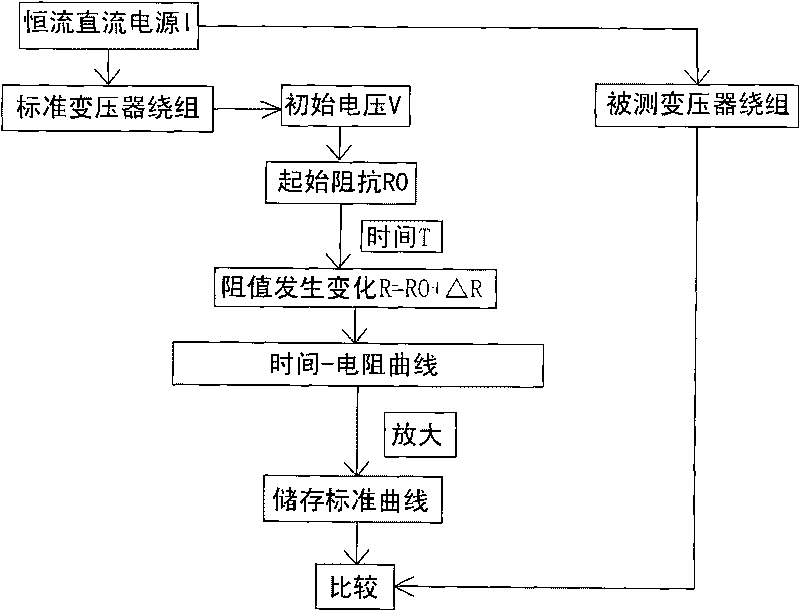

[0030] like image 3 Shown: apply constant current DC power to the transformer winding of known material, and sample the current to obtain a constant value of current I 0 , the voltage is sampled to obtain the initial voltage V 0 , get the starting resistance R of the transformer winding of known material 0 , continue to energize, the winding will continue to heat up within a certain period of time T, and the winding resistance will change R=R 0 +ΔR, by recording the changing voltage V of the voltage sampling during this time T xn and the constant value of the current I 0 , and calculate the standard time-resistance curve of the resistance of the standard transformer winding as a function of the heating time. For the tested transformer windings marked with the same capacity and the same wiring method as the standard transformer windings, apply a constant current DC source under the same temperature conditions, and sample the current to obtain a constant value of current I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com