Multiple large range laser scanning measurement method

A technology of laser scanning and measurement method, which is applied to measurement devices, optical devices, instruments, etc., can solve the problem that the efficiency of segmented scanning cannot increase the optical knife multiple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] 1. Measuring terminal composition.

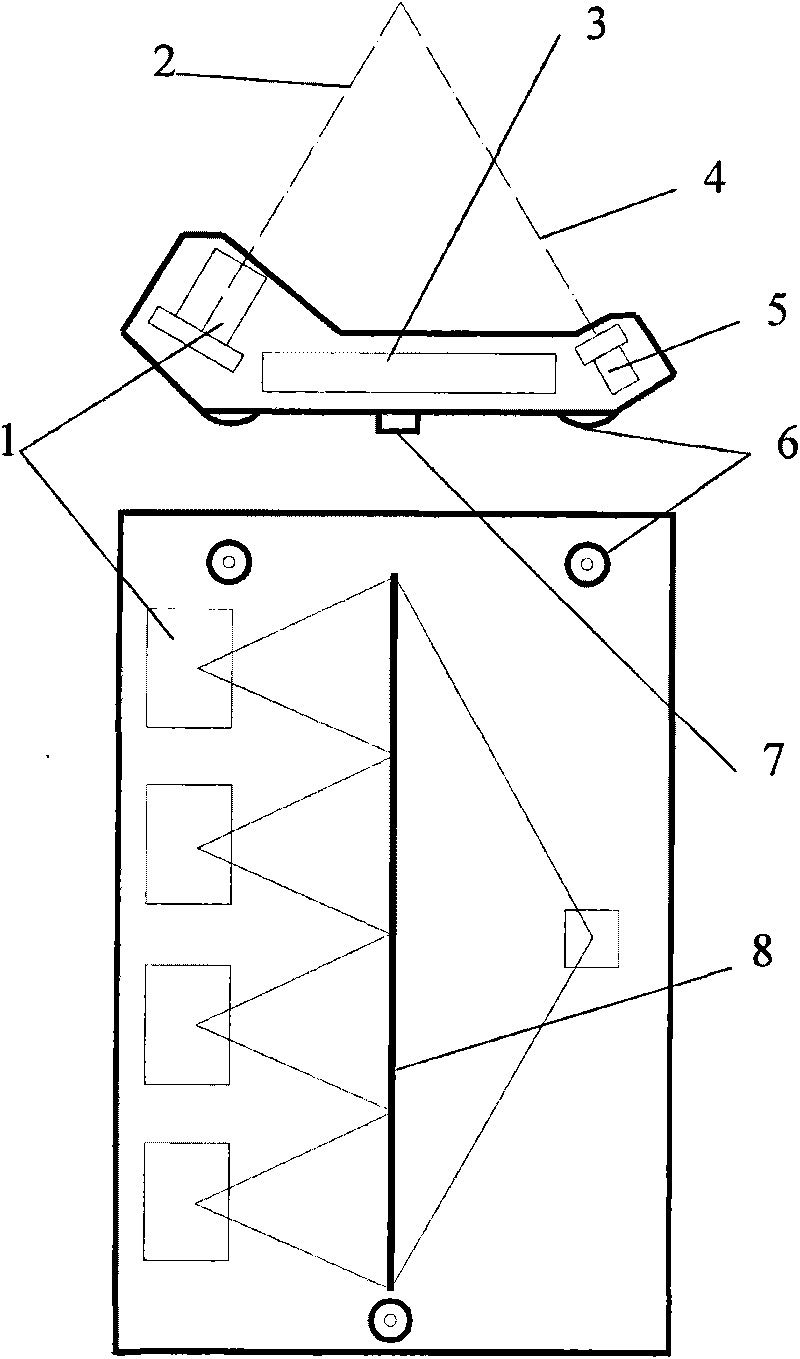

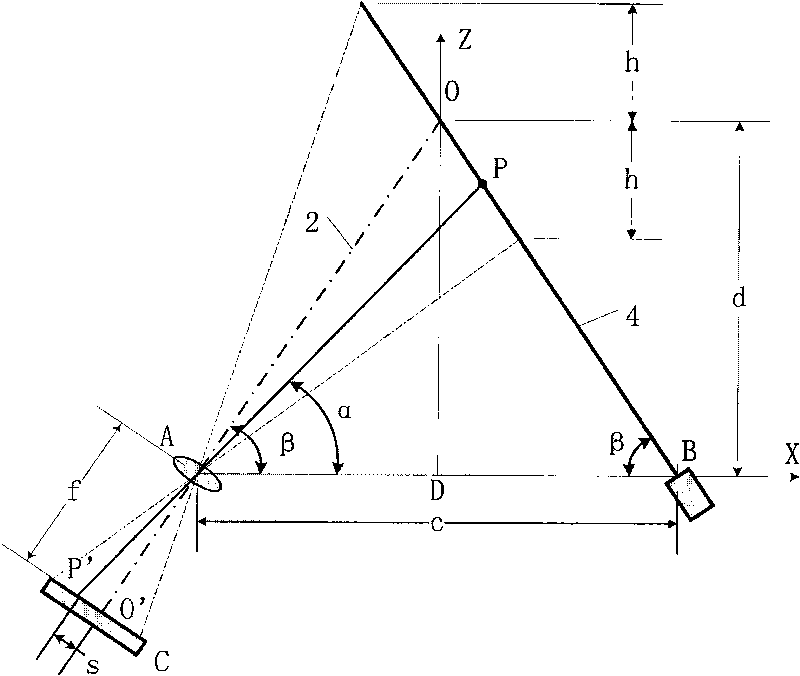

[0038] Such as figure 1 As shown, the multi-eye wide-range laser scanning measurement terminal is mainly composed of five parts: laser light knife projector 5, multi-eye high-precision digital camera 1, real-time image processing and communication control center 3, handheld mode positioning and attitude monitoring device 6, machine Load mode fixing thread 7, and terminal frame composition.

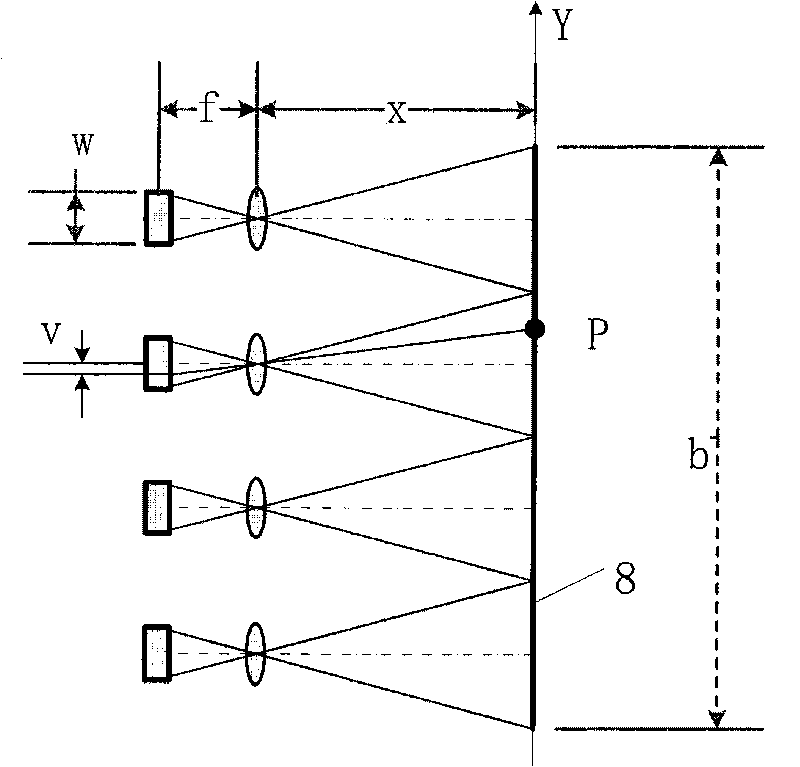

[0039] The function of the laser light knife projector 5 is to project a plane light beam 4 to the workpiece. The projection line 8 formed on the workpiece is very long and the scanning width is very wide. Four-eye (four) digital cameras 1 are equidistantly arranged along the direction of the projection line 8, and image the projection line in segments to ensure that the width of the projection line is fully utilized, thereby improving measurement efficiency. The real-time image processing and communication control center 3 processes the imagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com