Device and method for directional fracture of rocks

A directional fracture and rock technology, applied in blasting and other directions, can solve the problems of high packing quality, long rock cracking time, obvious climate impact, etc., to achieve good rock cracking effect, short cracking time, and saving mineral resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

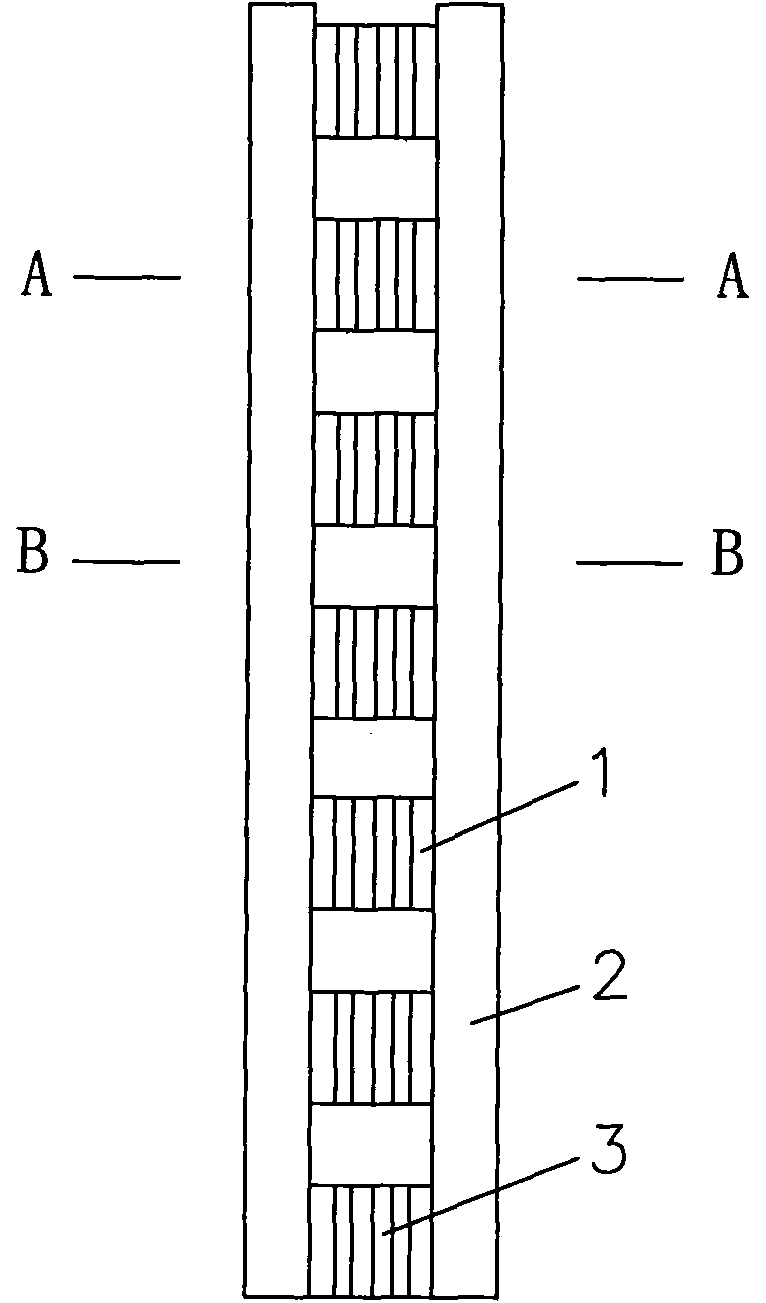

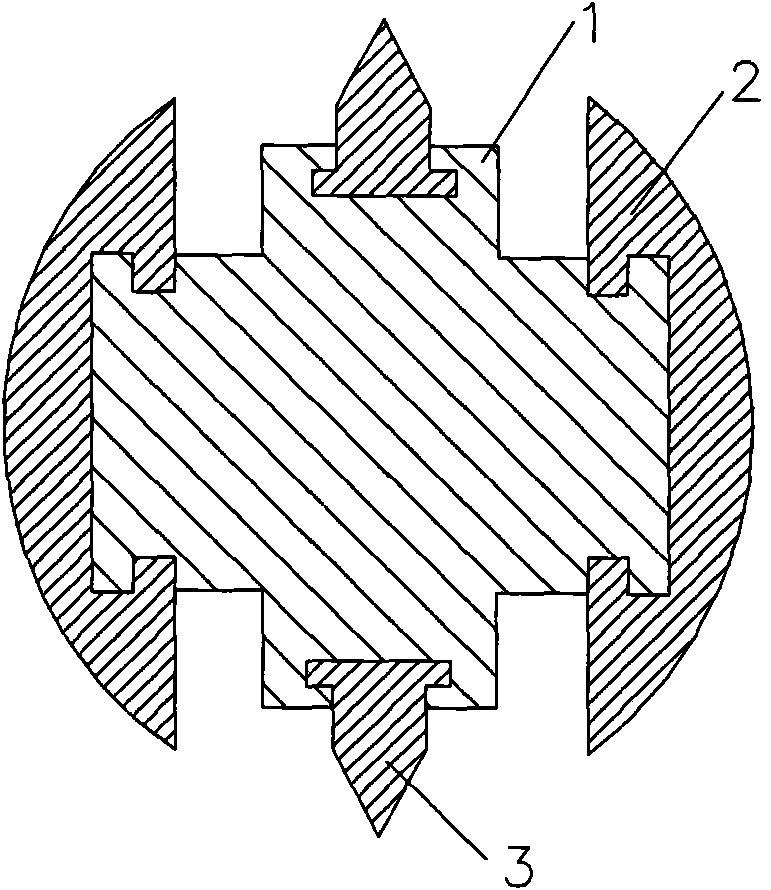

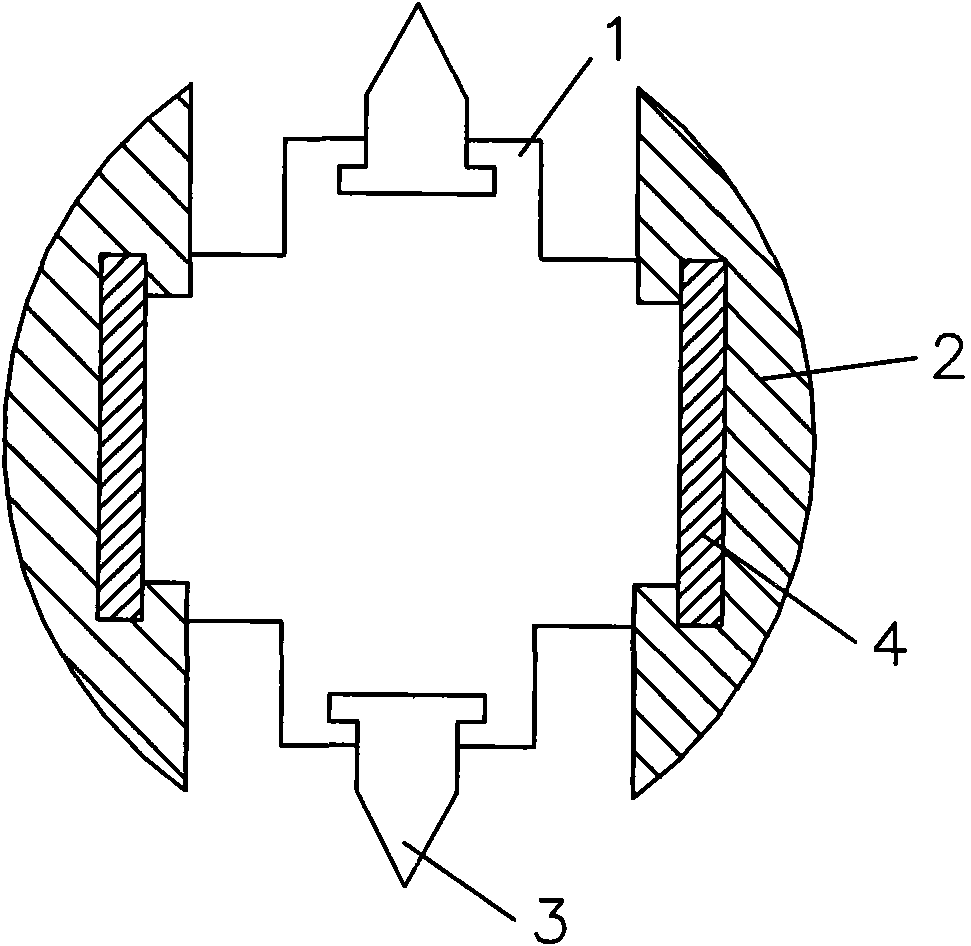

[0019] figure 1 , 2 , 3, the directional fracture device of the present invention is composed of a shape memory alloy body 1, a pressure transmitting body 2, a straight blade 3 and a spacer 4. The pressure transmission body 2 is composed of two arc-shaped bodies, and the inner side of the arc-shaped body is symmetrically opened with convex grooves. The shape memory alloy body 1 adopts a shape memory alloy body with a two-way memory function, such as a two-way memory titanium-nickel alloy, iron Base and copper-based memory alloys, or ordinary porous shape memory alloys, which are processed into cross-shaped sections at high temperatures, and pressure is applied along the cross-shaped sides at low temperatures to compress them to produce pre-deformation, and then shape memory alloy body 1 Longitudinal grooves are processed on the four branches of the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com