Method for filling solid and fully mechanizing and recovering room type coal pillar

A room-type coal pillar and solid filling technology, which is applied in the fields of filling, ground mining, mining equipment, etc., can solve the problems of hard roof, low degree of mechanization, and low production efficiency, and achieve high production efficiency and improve recovery rate. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

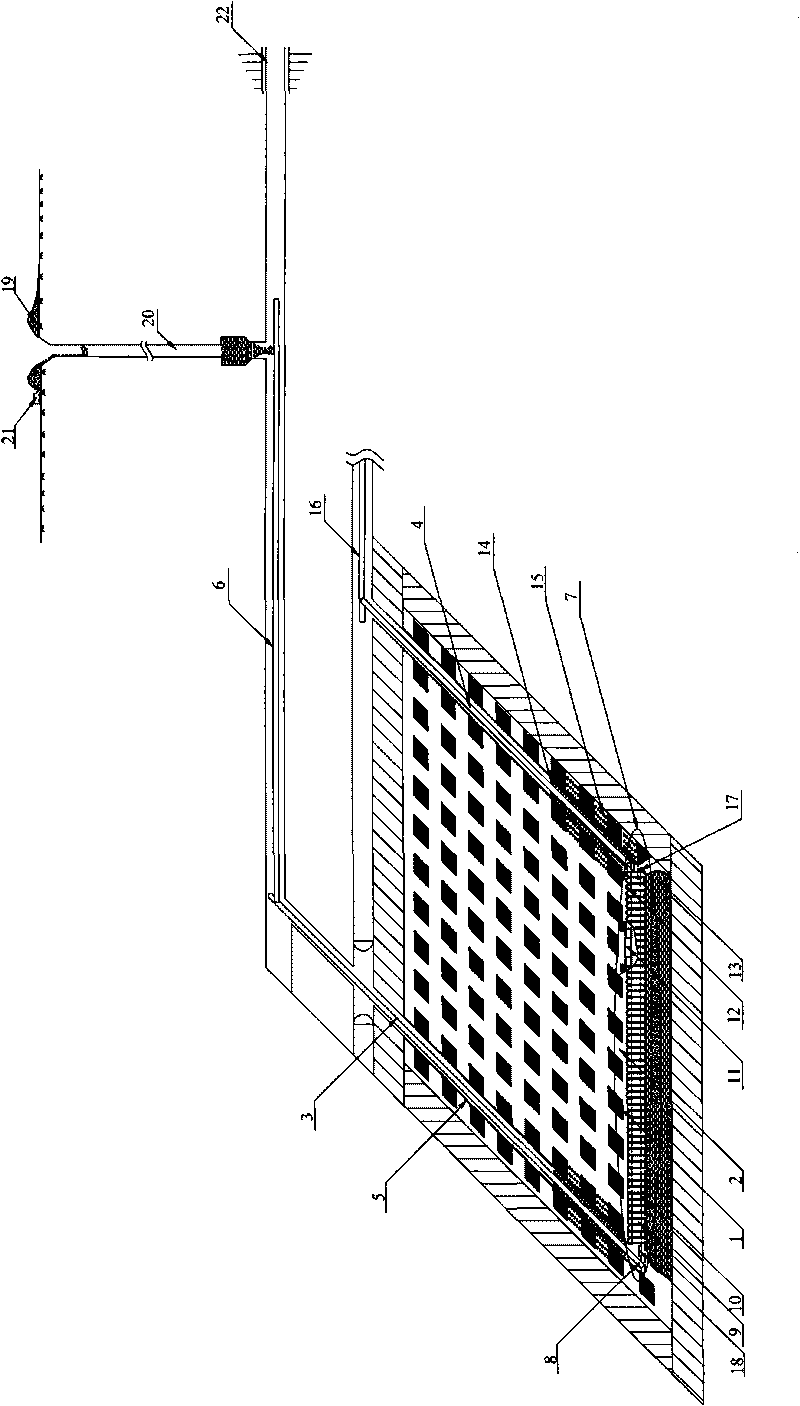

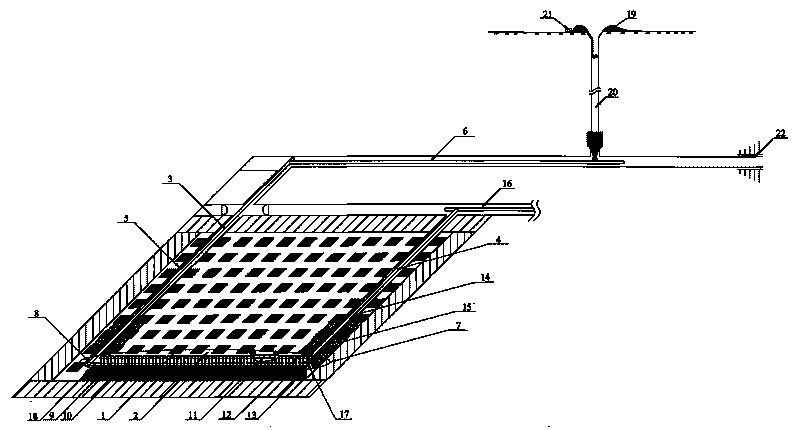

[0015] Take the No. 2 well of a mine in Inner Mongolia Yitai Coal Co., Ltd. as an example. The mine is located in the Boniuchuan census area of Dongsheng Coalfield, Inner Mongolia Autonomous Region. The coal seam in the design recovery mining area belongs to a single inclined coal seam , the inclination angle is 1-3°, the average buried depth is 170m, the average thickness is 6.34m, the size of the mining coal room is 8×8×4.5m, and the size of the reserved coal pillar is 8×8×4.5m. According to the conventional design, the length of the filling mining face is 150m, the advancing length is 670m, and the mining height is 6.0m. The method of solid filling fully mechanized recovery of room-type coal pillars is as follows:

[0016] (1) First, the roof of the coal pillar 1 and the coal room 2 in the recovery area of the room-type coal pillar is strengthened and supported by the anchor net cable support method;

[0017] (2) Arrange the solid object transportation entryway 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com