Pre-control roof open stoping spallation subsequent filling mining method

A technology of backfill mining and pre-control roof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

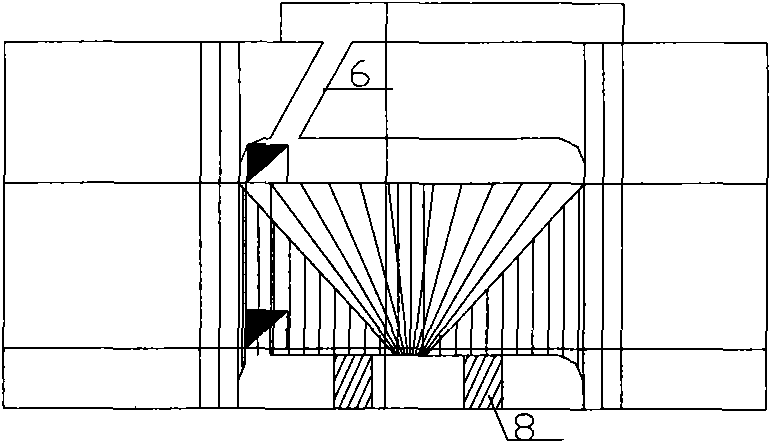

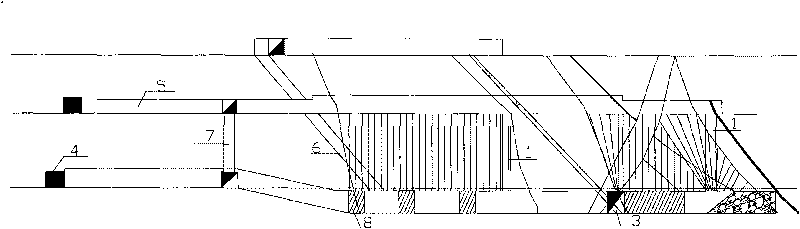

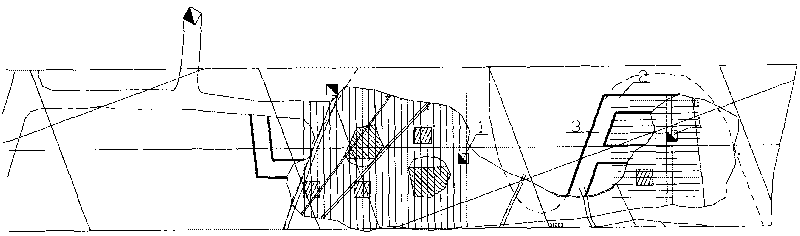

Image

Examples

Embodiment Construction

[0017] 1. Mining and cutting project layout:

[0018] Five-section hanging wall stope: Excavation roadway along the vein is excavated between the upper and lower walls, and two access roads through the veins are excavated in this exit roadway and the connecting road between the original upper and lower walls to form three access roads. An artificial point column is arranged near the connecting road between the upper and lower walls, and the excavation slope is 90 degrees to cut the patio to the six-section hanging wall stope to form the initial free surface.

[0019] Five-section footwall stope: the original stope connecting road is excavated with an ore exit route to the stope, and three artificial point columns are arranged in the stope to form three access routes and six cutting trenches with the original point columns, and the excavation slope is The 90-degree cut from the patio to the footwall stope of six sections forms the initial free surface.

[0020] Six-section sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com