Multi-direction rotary jetting stirring grouting reinforcement construction method for constructing underground structure and soil body by cover excavation and underground excavation and supporting structure thereof

A technology for underground structures and supporting structures, which is applied to underwater structures, buildings, earthwork drilling and mining, etc., and can solve problems such as difficult construction, difficult construction, and difficult handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

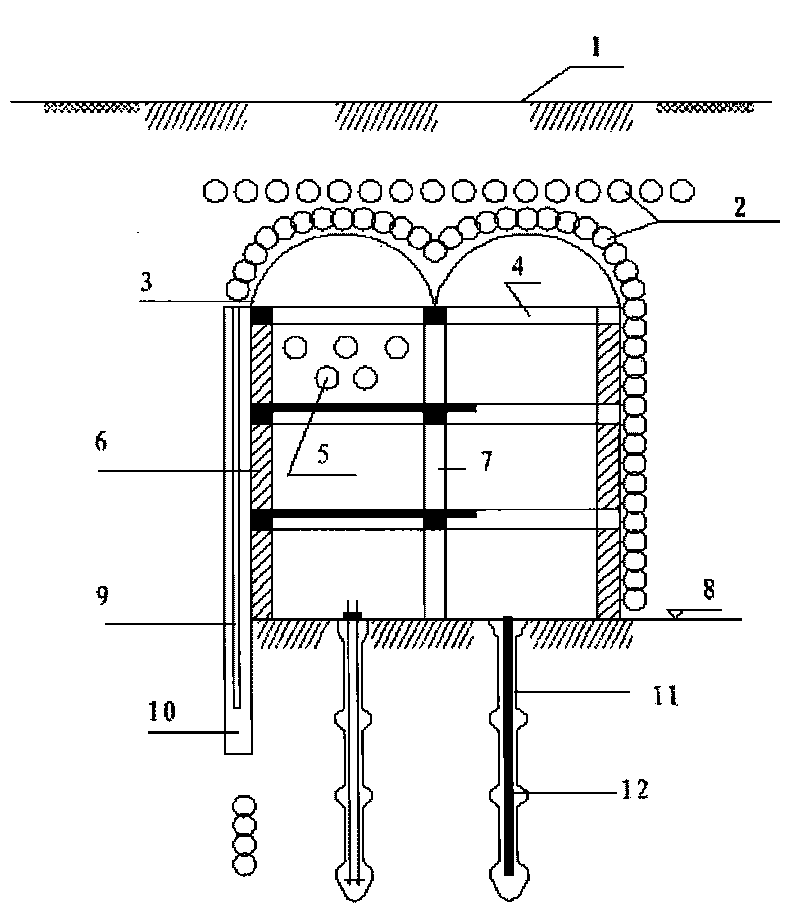

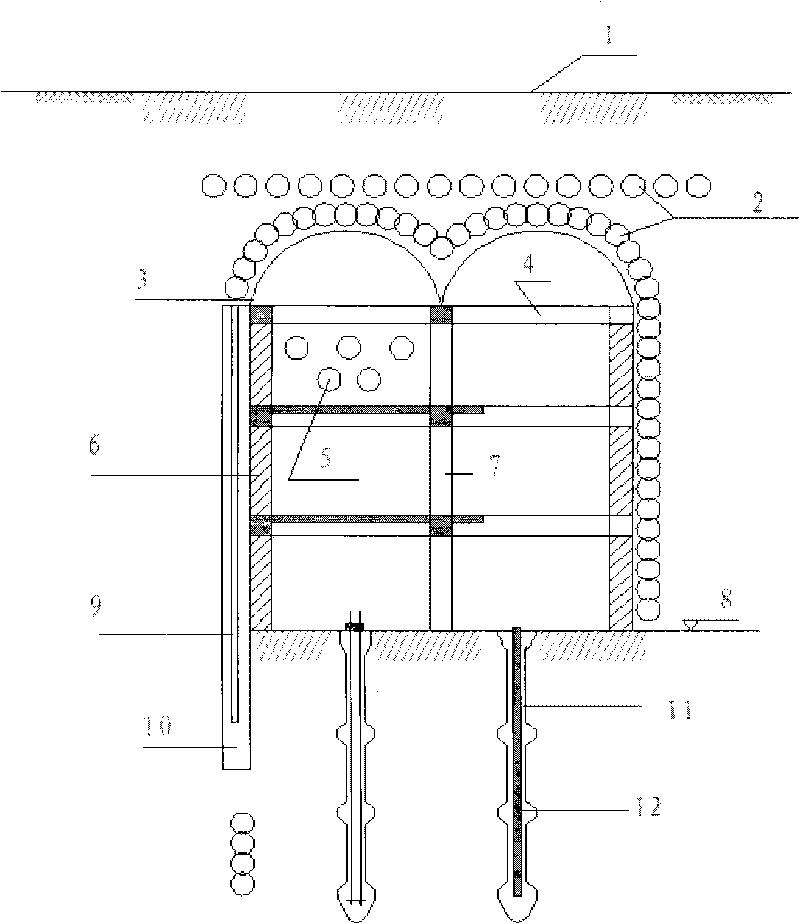

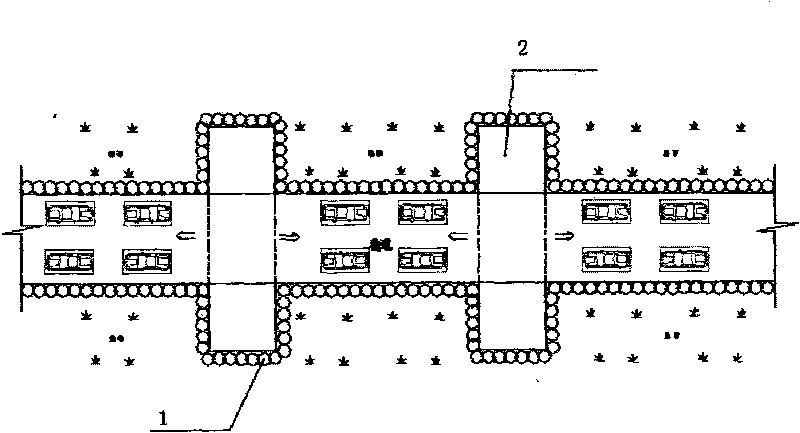

[0005] Relevant technical content of the present invention and detailed description are as follows

[0006] 1. Cover and dig method

[0007] Firstly, 1. Make a water-stop curtain and soil retaining wall around the underground structure to be built. 2. Excavate the soil from the ground to the position where the upper cover is made, and make the upper cover on the excavated working surface, and the upper cover Press the slab on the top of the supporting pile wall around, 3 dig a vertical shaft and a horizontal tunnel at the excavation opening of the retaining wall, 4 the tunnel enters the side of the supporting wall and the column, and dig the wall and column to make the wall and column 5. Construct the main body of the underground structure under the good cover of advanced reinforcement and active support. 6. Construct the stirring core pile and the reinforcement core machine in the underground space, and make the bottom plate on the top of the pile.

[0008] 2. Underground ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com