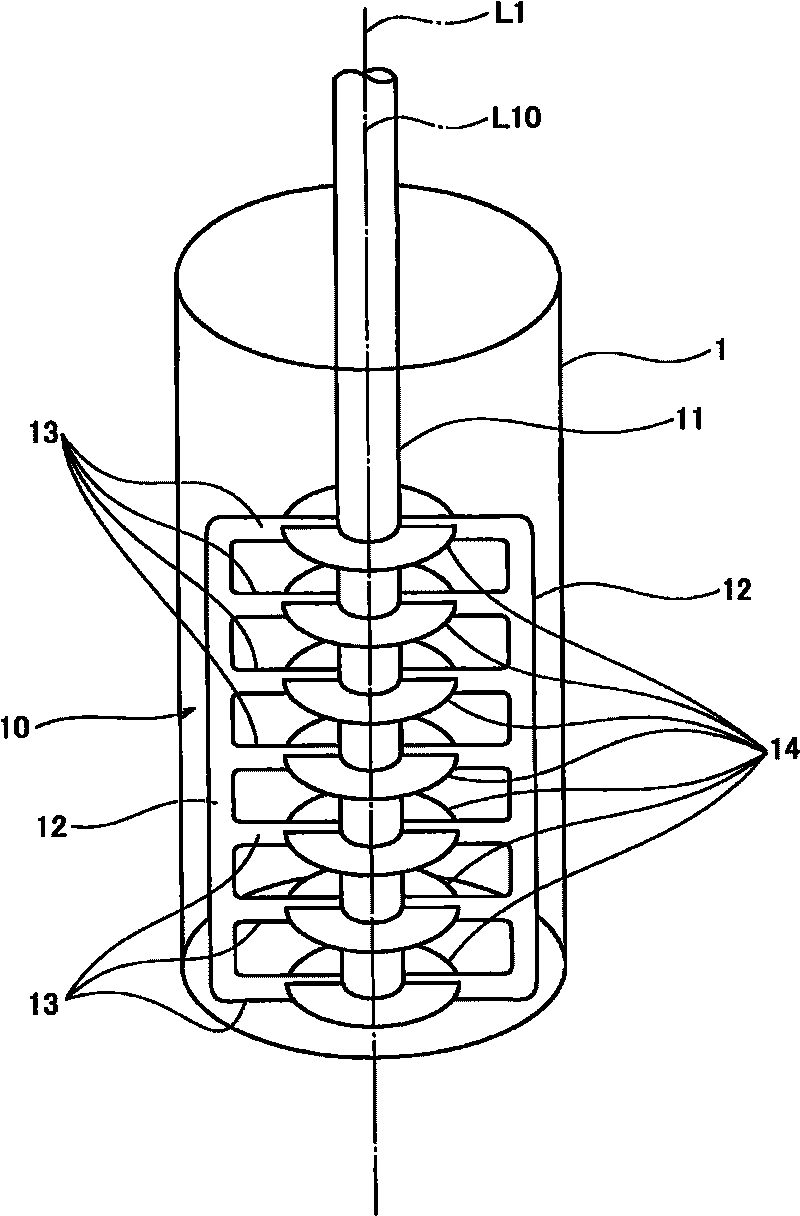

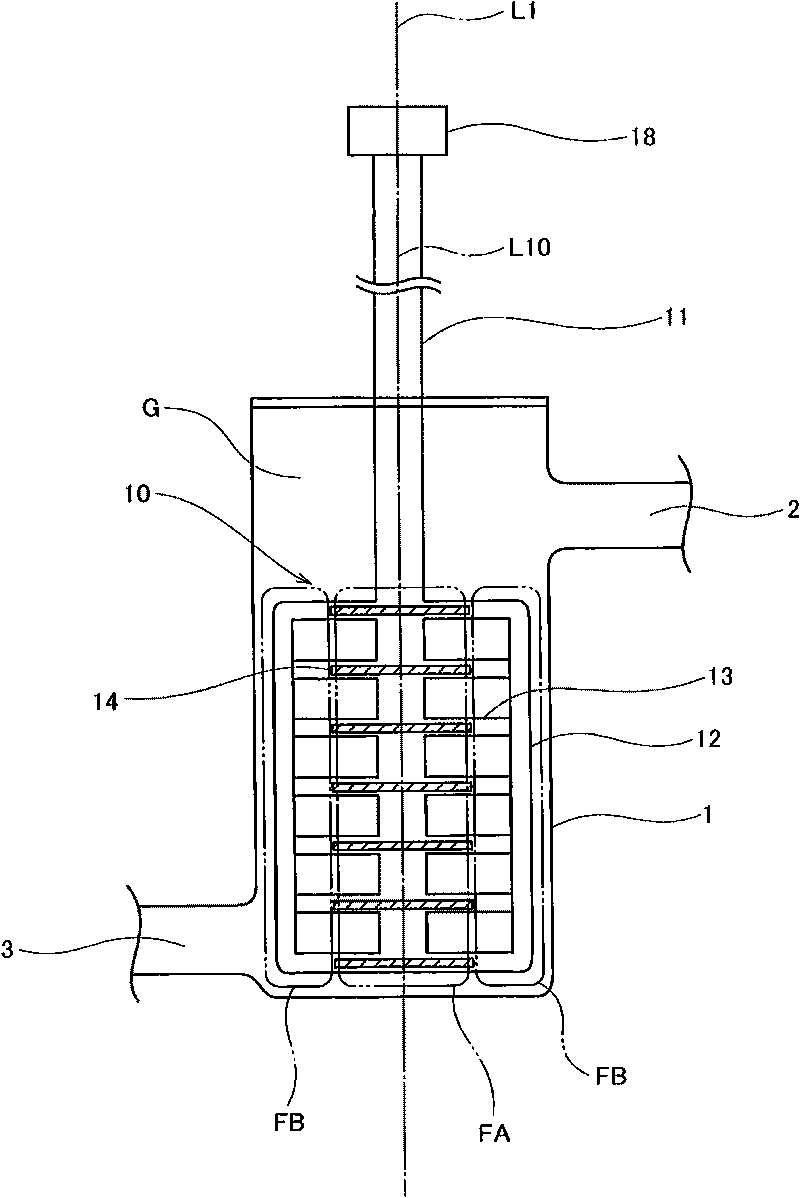

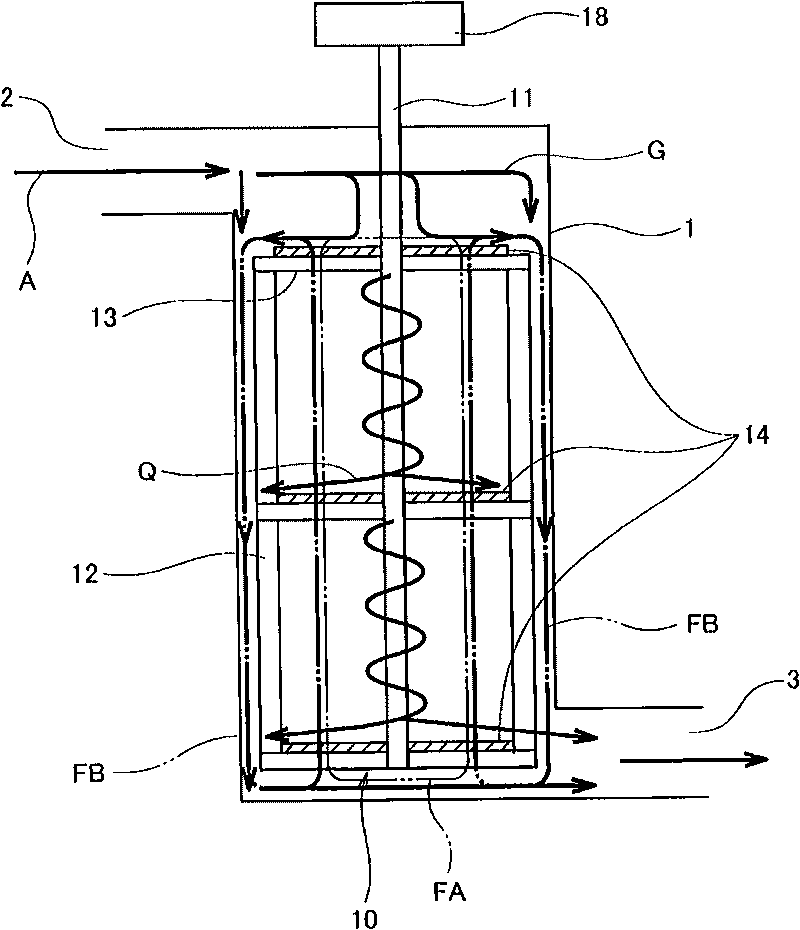

Stirring blade for molten glass and stirring device therefor

A technology of molten glass and stirring wings, which is applied in glass production, glass furnace equipment, glass manufacturing equipment, etc. It can solve the problems of low stirring effect and weak shearing effect of molten glass, so as to improve rigidity, promote stirring, eliminate or reduce The effect of heterogeneous glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] Next, specific examples will be described.

[0071] The viscosity, temperature, and flow velocity of the molten glass used here are roughly as follows.

[0072] Temperature: 1450℃~1550℃

[0073] Viscosity: 900~2000 Poise (100Pa·s)

[0074] Flow rate: 3cm / min~6cm / min

[0075] In addition, the composition of molten glass is shown in Table 1.

[0076] Table 1

[0077] Composition of molten glass (mol%)

[0078] SiO 2

50~70

Al 2 o 3

5~15

B 2 o 3

5~15

MgO

0~3

CaO

3~10

SrO

1~3

BaO

0~5

Na 2 o

0~1

K 2 o

0~1

As 2 o 3

0~1

Sb 2 o 3

0~1

SnO 2

0~2

[0079] SiO 2

50~70

Fe 2 o 3

0~2

ZrO 2

0~2

[0080] The raw material of stirring tank and stirring wing is platinum or platinum alloy.

[0081] Examples of platinum alloys include "platinum-rhodium all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com