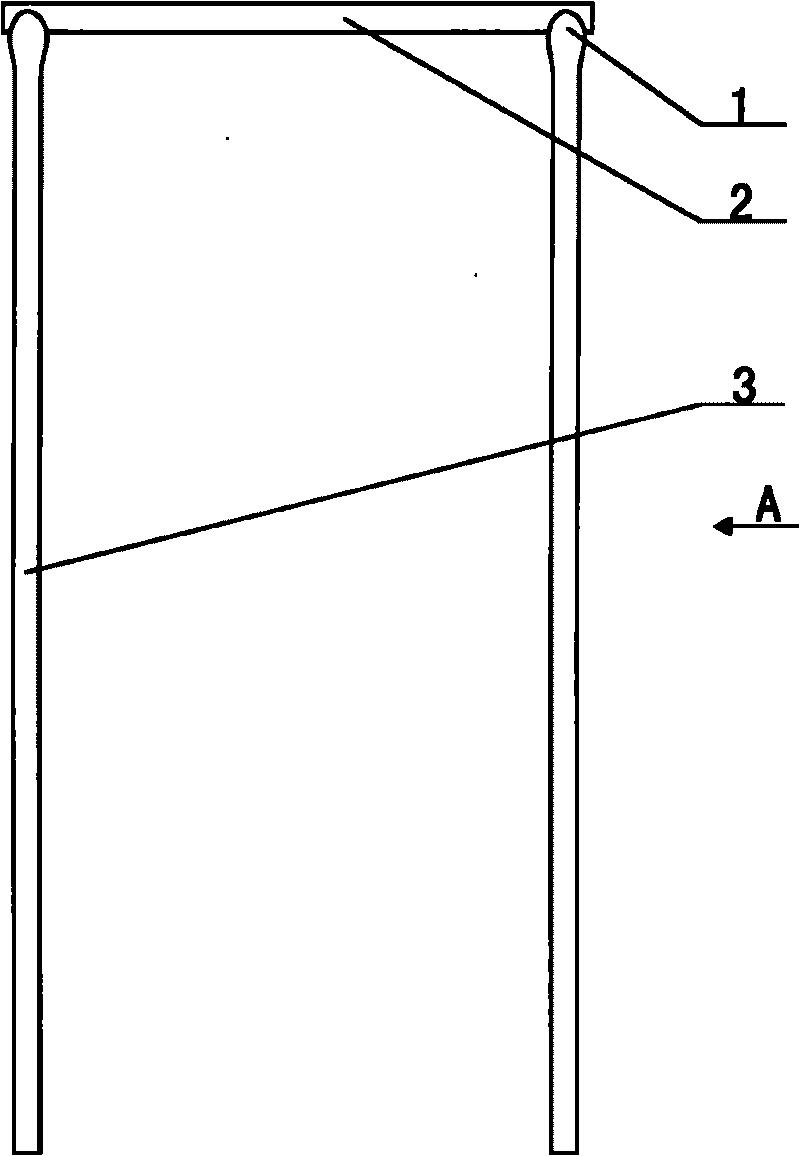

Whole 'U'-shaped silicon core structure

A silicon core and overall technology, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of poor contact at the lap joint, high resistance, poor quality of polysilicon, and lodging of the silicon core, so as to avoid the lodging of the silicon core, The effect of improving the rate of first-class products and uniform resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention can be explained in more detail with reference to the following examples; however, the present invention is not limited to these examples.

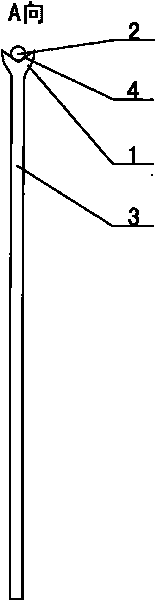

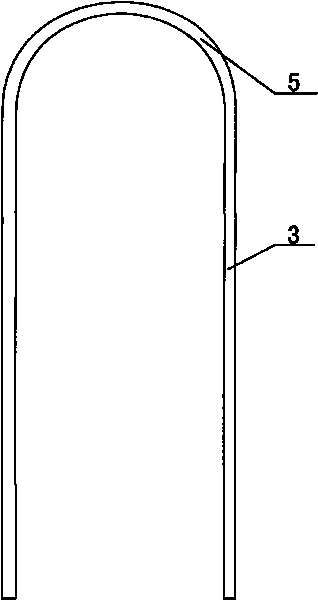

[0019] combined with Figure 2-6 The overall "U"-shaped silicon core structure, including the silicon core body, is image 3 The middle part of the structure silicon core that the present invention provides is circular arc 5 shape, and two vertical silicon cores 3 are respectively connected with the two ends of circular arc 5; Figure 4 The structure provided by the present invention is two circular arcs 5, and a straight connection silicon core 6 is arranged between the circular arcs 5 and 5 for connection, and the two vertical silicon cores 3 are respectively connected to the outer ends of the two circular arcs 5; combine Figure 5 The structure provided by the present invention is that two directly connected silicon cores 6 are connected with three circular arcs 5 to form a bending section of the silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com