Surface heat source

A heat source and heating element technology, applied in the field of surface heat source based on carbon nanotubes, can solve the problems of low carbon fiber electrothermal conversion efficiency, insufficient carbon fiber strength, unfavorable energy saving and environmental protection, etc., and achieve high electrothermal conversion efficiency, long service life, heat generation uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The surface heat source provided by the present invention will be described in detail below with reference to the drawings and specific embodiments.

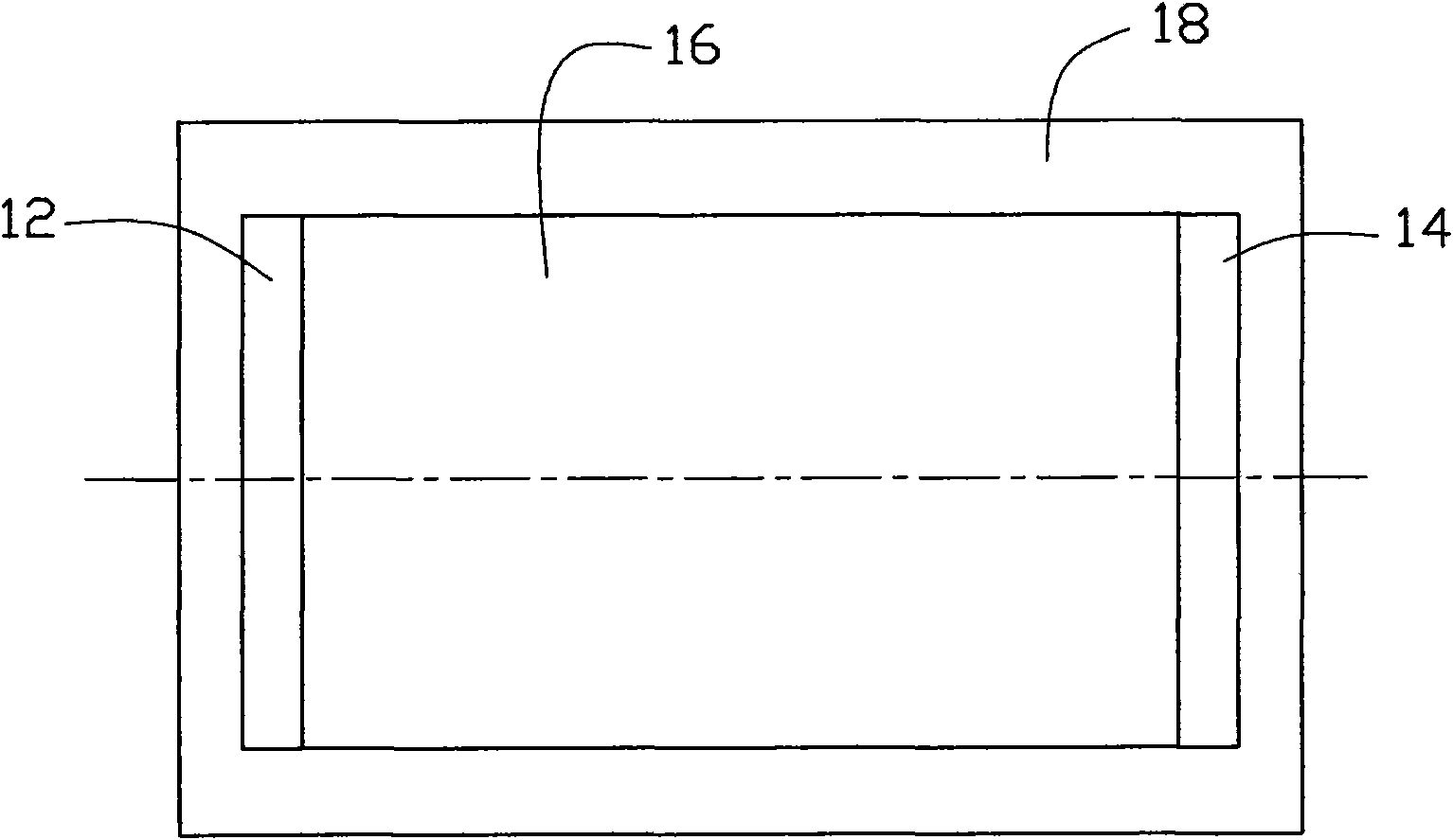

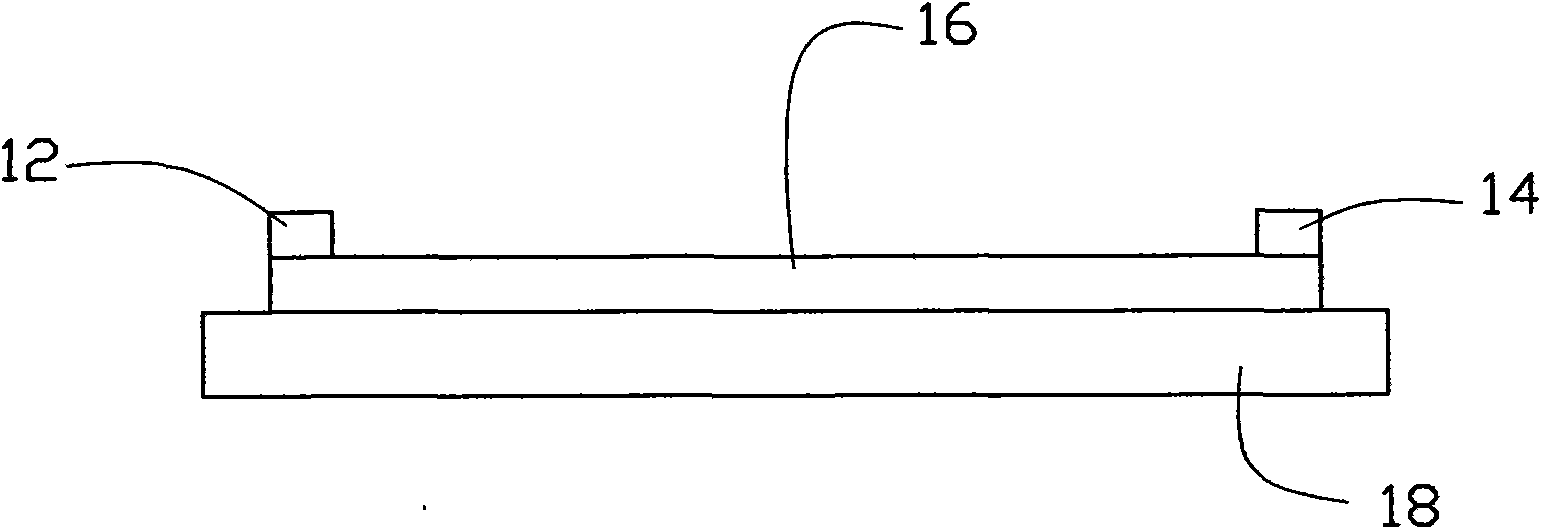

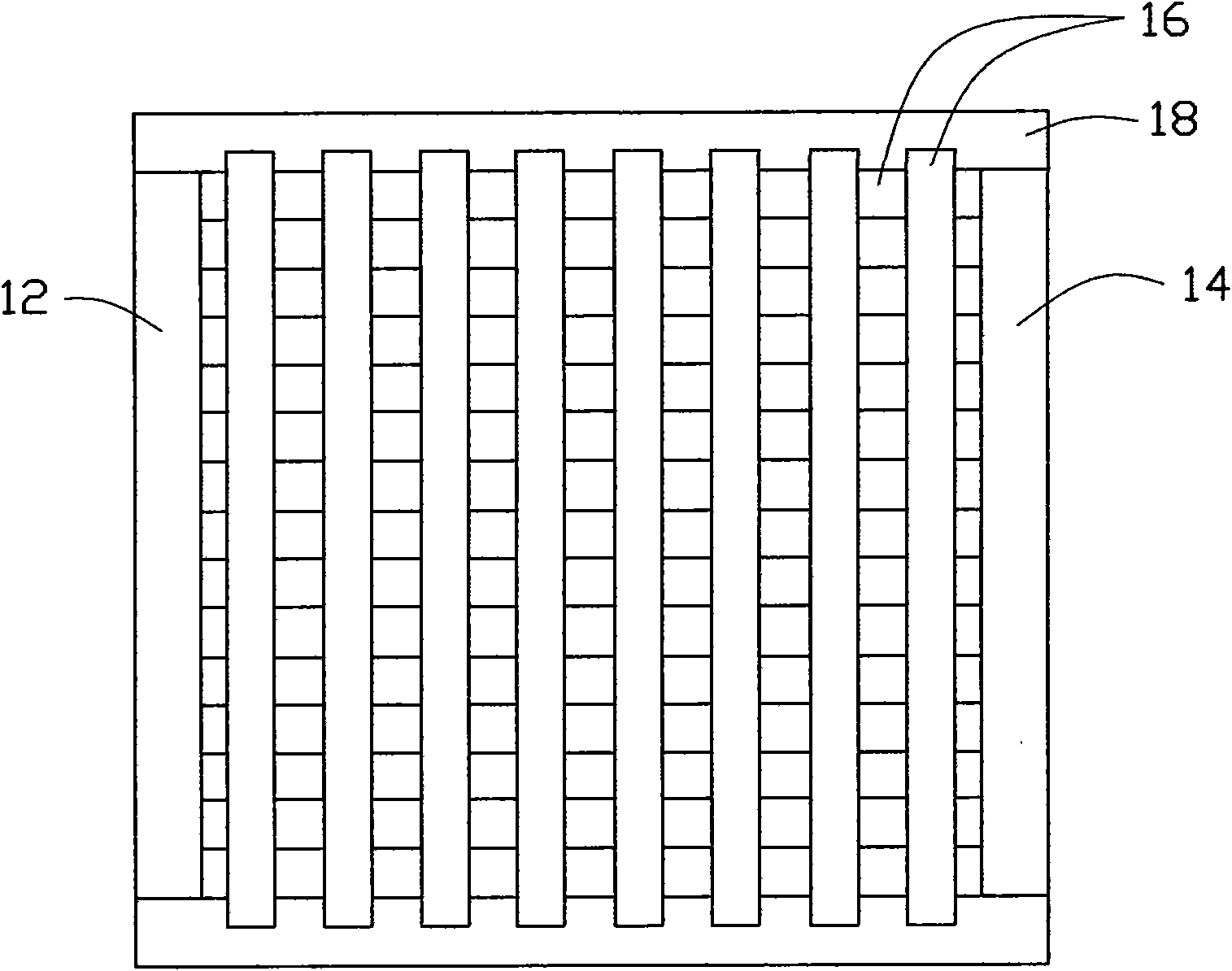

[0019] see figure 1 and figure 2 , The first embodiment of the present invention provides a surface heat source 10, the surface heat source 10 is a two-dimensional structure, that is, the surface heat source 10 is a structure extending along a two-dimensional direction. However, it should be pointed out that even if there is a two-dimensional structure with a certain thickness, the embodiment of the structure that is still regarded as or approximately regarded as two-dimensional structure macroscopically, such as: plate-shaped, film-shaped and other structures, should also be regarded as protected by the present invention scope.

[0020] The surface heat source 10 includes a heating element 16 , a first electrode 12 and a second electrode 14 . The heating element 16 is electrically connected to the first electrode 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com