Full-automatic distributing and conveying appliance of plastic-rubber raw materials

A technology for conveying devices and raw materials, applied in valve devices, valve operating/release devices, engine components, etc., can solve the problems of inability to apply automatic distribution discs, large size of switching valves, and inability to apply in large quantities, etc., to achieve compact structure, Reduction of residual amount, easy production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

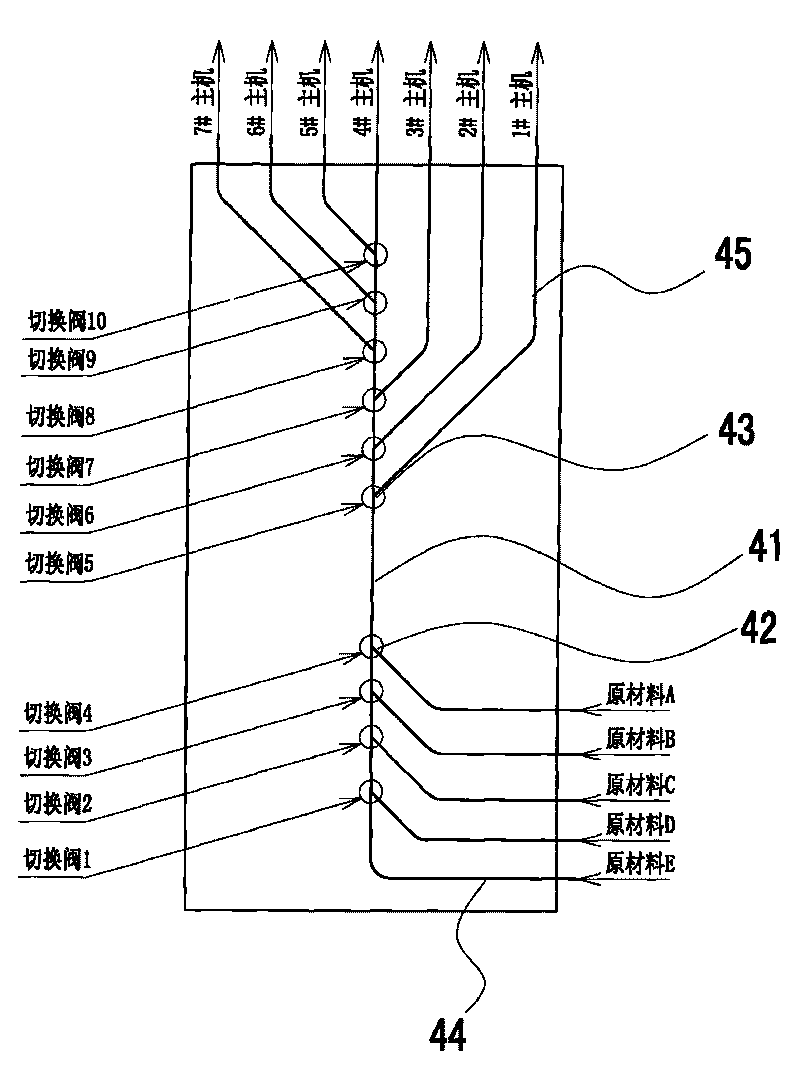

[0025] see figure 1 , the rubber and plastic raw material automatic distribution and conveying device of the present invention is used to convey various raw materials to multiple molding hosts respectively, including a conveying main pipe 41, multiple feeding three-way switching valves 42, and multiple discharging three-way switching valves 43 , a plurality of feeding branch pipes 44, a plurality of discharging branch pipes 45 and a PLC control system (not shown); a plurality of feeding three-way switching valves 42 and a plurality of discharging three-way switching valves 43 are installed in series on the main pipe 41 in series , each feed branch pipe 44 is respectively connected with the third port of a feed three-way switching valve, one end of each discharge branch pipe 45 is respectively connected with the third port of a discharge three-way switch valve, and the other end is respectively It is connected with one forming host, and the PLC control system controls the actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com