Size control method for precision processing of pyramid sleeve and measurement clamping plate

A technology of size control and pyramid, which is applied in the processing field of pyramid sleeves, can solve the problems of square pyramid sleeves or reel precision quality influence, dimensional accuracy is not easy, etc., and achieve the effect of simple operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

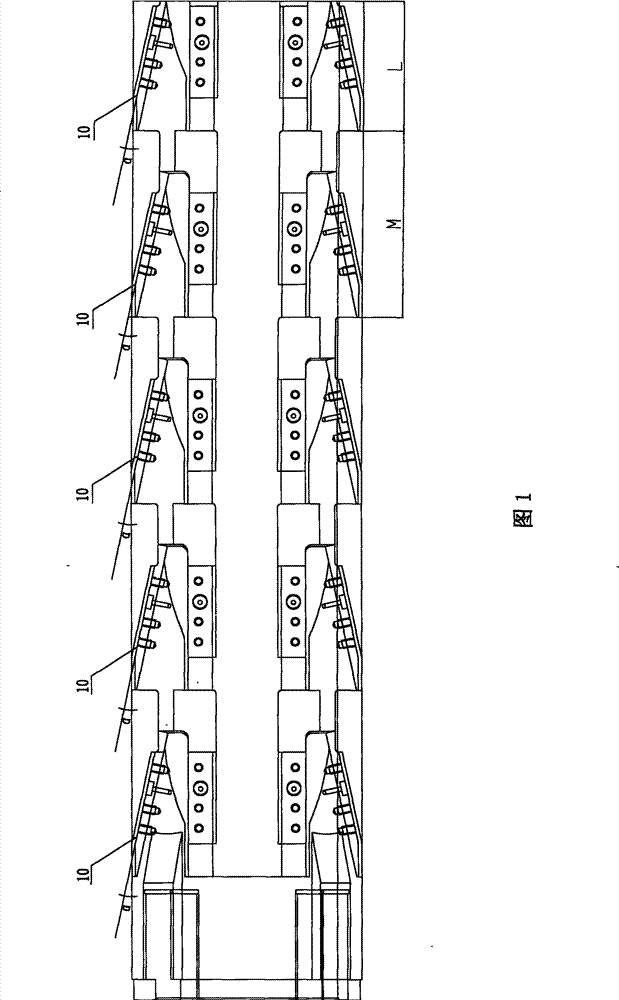

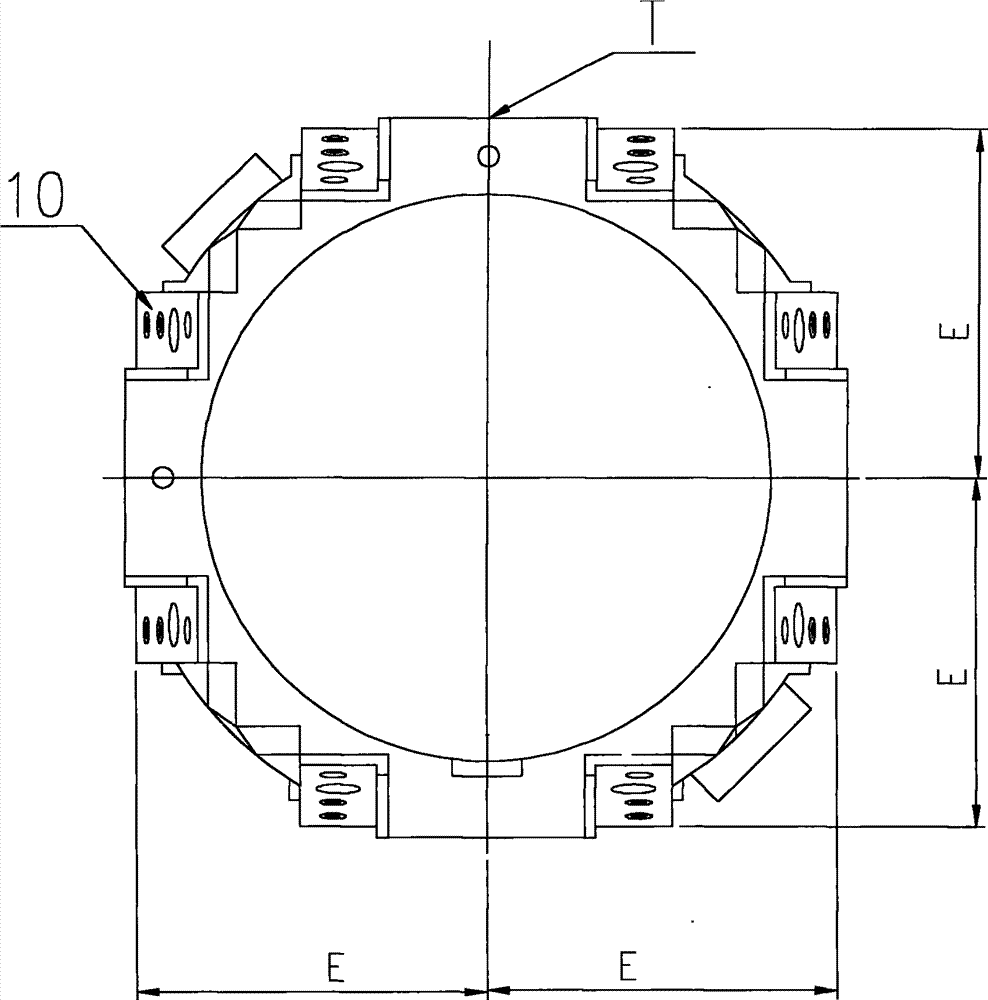

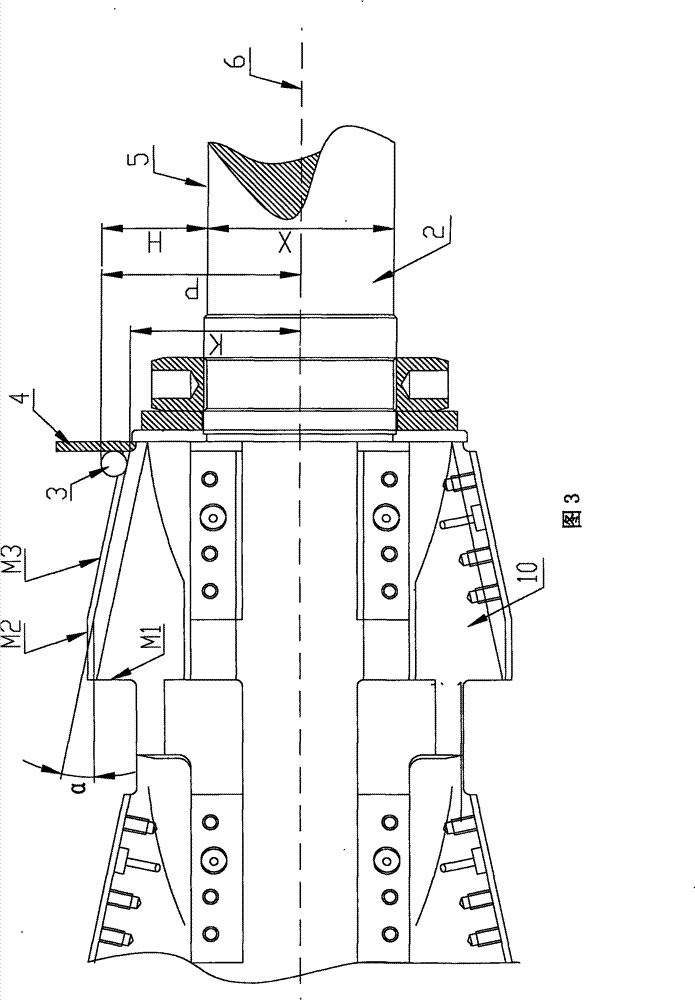

[0027] Such as image 3 As shown, the measurement dimension P is calculated based on the nominal dimension K and α value, that is, the measurement dimension P is determined by using the dimension K and α value as the reference data, and K is based on the inner hole center 6 of the square pyramid sleeve. The measurement reference guarantees that, for this reason, the present invention still uses the inner hole center 6 of the quadrangular pyramid sleeve as the measurement reference, and at the same time uses the α value as the data that must be considered to find a new simple, controllable and convenient size control method.

[0028] from image 3 It can be seen that as long as the radial and axial dimensions of the highest point of the pyramid 10 are determined, that is, when the dimensions of the side M1 and the top surface M2 of the pyramid 10 are guaranteed, the angle α value of the working inclined plane M3 of the pyramid 10 is guaranteed at the same time , the nominal di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com