Preparation method of compound photocatalytic water purification material

A composite photocatalytic and water purification technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, molecular sieve catalysts, etc., can solve problems such as lack of photocatalytic activity, and achieve the effect of simple process and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 0.5g of the above-mentioned titanium dioxide powder and place it in 100ml of ethanol solution, add 0.001g of trimethylolethane, 100kHz ultrasonic dispersion treatment for 20 minutes, add 4.5g of commercially available 5A zeolite molecular sieve, and mix well The slurry is mechanically milled on a ball mill for 1 hour, the weight ratio of balls to materials is 5:1, and the milling speed is 120 rpm. Dry the mixed powder obtained after the above ball milling at 110°C for 1 hour, and then bake it in air at 450°C for 5 hours to obtain the product, which is recorded as 10wt% TiO 2 / 5A.

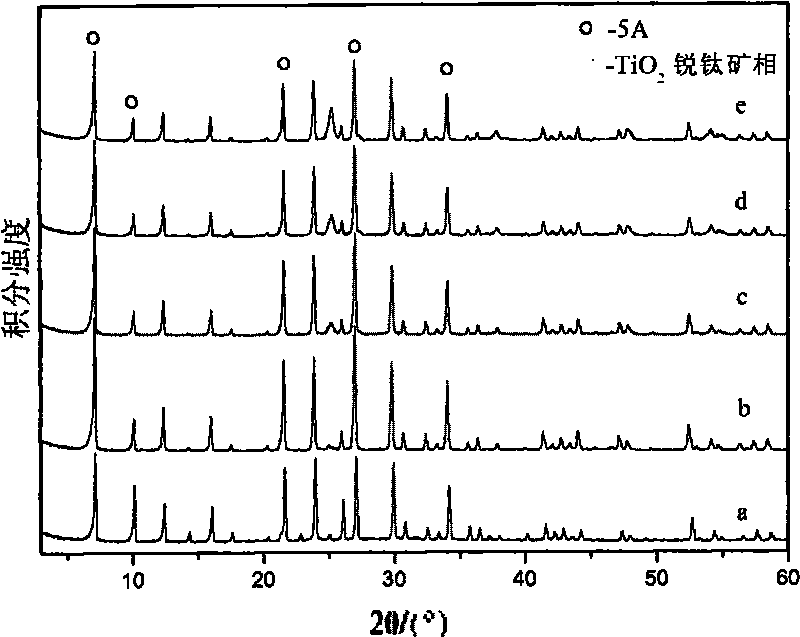

[0031] The product was characterized by X-ray Diffraction, Field Emission Environmental Scanning Electron Microscopy, please refer to figure 1 : a is the X-ray diffraction figure of 5A zeolite molecular sieve, b, c, d, e are the compound that the present invention method that forms on 5A zeolite molecular sieve and supports nano-titanium dioxide 1%, 5%, 10%, 15% respectively X-ray dif...

Embodiment 2

[0034] Weigh 0.75g of nano titanium dioxide powder and place it in 150ml of ethanol solution, add 0.002g of trimethylolethane, 50kHz ultrasonic dispersion treatment for 40 minutes, add 4.25g of 13X zeolite molecular sieve, and mechanically mill the mixed slurry on a ball mill for 1.5 hours, the weight ratio of balls and materials is 8:1, and the milling speed is 140 rpm. Dry the mixed powder obtained after the above ball milling at 110°C for 1.5 hours, and then bake at 400°C in air for 6 hours to obtain the product, which is recorded as 15wt% TiO 2 / 13X.

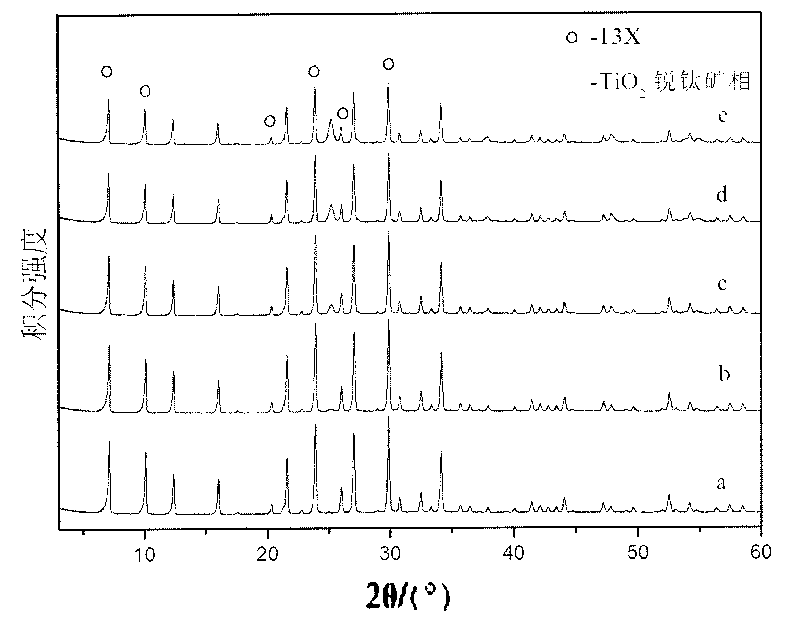

[0035] The product was characterized by X-ray Diffraction, Field Emission Environmental Scanning Electron Microscopy, please refer to figure 2 : In the figure, a is the X-ray diffraction pattern of 13X zeolite molecular sieve, and b, c, d, e are the composite materials formed by loading nano-titanium dioxide 1%, 5%, 10%, and 15% on 13X zeolite molecular sieve respectively X-ray diffraction pattern.

[0036] The product w...

Embodiment 3

[0038] Weigh 1g of nano-titanium dioxide powder and place it in 200ml of ethanol solution, add 0.002g of trimethylolethane, 20kHz ultrasonic dispersion treatment for 60 minutes, add 4g of medical stone, and mechanically mill the mixed slurry on a ball mill for 1 hour , the weight ratio of the ball and the material is 2:1, and the milling speed is 150 rpm. Dry the mixed powder obtained after the above ball milling at 110°C for 1 hour, and then bake it in the air at 500°C for 3 hours to obtain the product, which is recorded as 20wt% TiO 2 / medical stone.

[0039] The product was characterized by X-ray diffraction and field emission environmental scanning electron microscopy: nano-titanium dioxide has been successfully loaded on the surface of medical stone, and the size of nano-titanium dioxide and medical stone are 30 nanometers and 50 microns, respectively, which are consistent with those before loading.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com