Liquid guide flow type vertical sieve tray device

A sieve tower, liquid technology, applied in distillation separation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reducing the separation efficiency of trays, affecting the uniformity and ordering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described in conjunction with accompanying drawing:

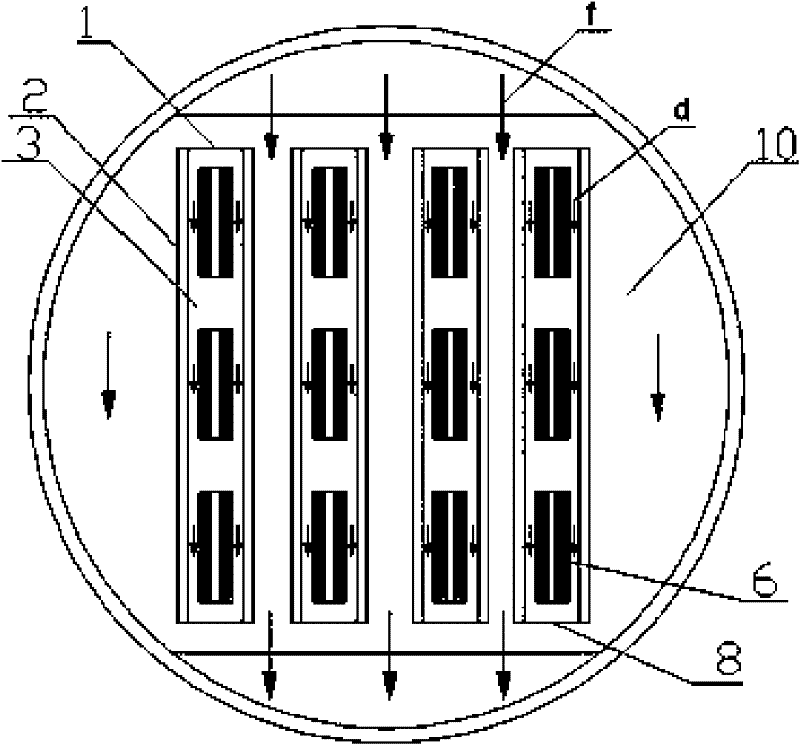

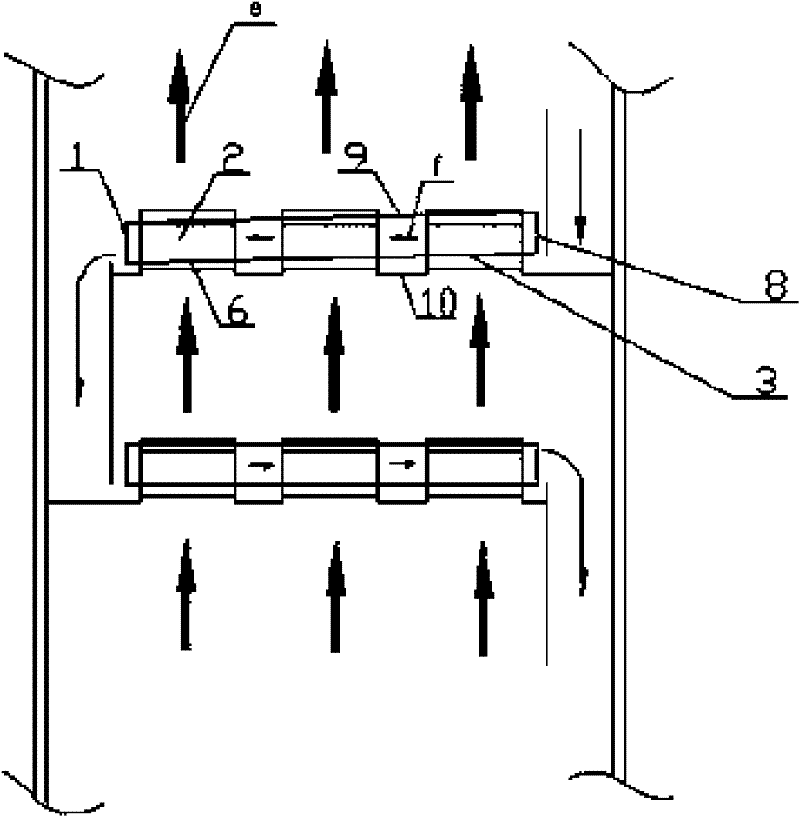

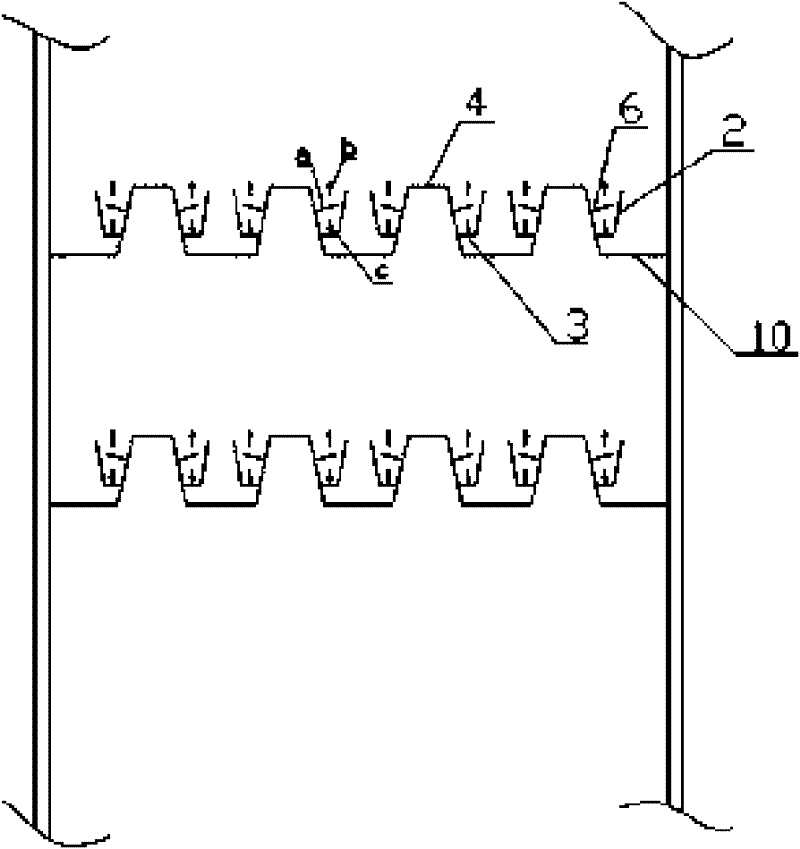

[0024] The structure of a liquid diversion type vertical sieve tray device is mainly composed of baffle plates and traditional gas-liquid contact mass transfer elements. Wherein the baffle can be a rectangular baffle (such as Figure 4 shown), or round baffles (such as Figure 5 shown), the entities of the two types of baffles all include the bottom surface 3, the side end surface 2 and the rear end surface 1, specifically, the front end surface 8 and the upper end surface 9 are completely open, and the rear end surface 1 and the bottom surface 3 are closed. In addition, the baffle plate The side end surface 2 and the bottom surface 3 are 90°, 110°, 135°, and the opening area of the bottom surface 3 is circular or square; the types of traditional gas-liquid contact mass transfer elements combined with baffles are trapezoidal (such as Figure 6 shown), rectangle (such as Figure 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com