Huperzine A solid composition and preparation method thereof

The technology of a solid composition and huperzine A is applied in the directions of pharmaceutical combinations, pharmaceutical formulations, medical preparations of inactive ingredients, etc., which can solve the problems of adverse reactions, content reduction, affecting treatment effects, etc., and achieves easy industrialization. The effect of production, stable quality and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

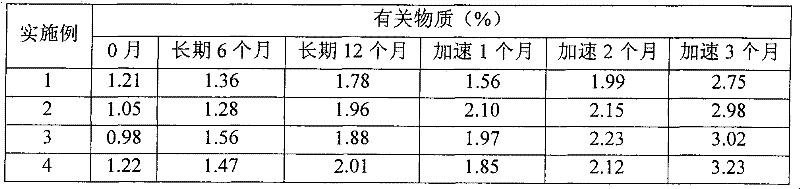

Examples

Embodiment 1

[0016] Dissolve 0.5g of citric acid in 60ml of water, take about 50ml and add 0.05g of huperzine A to dissolve, then add it to the granulator, rinse the container where the main drug is dissolved with the remaining 10ml of citric acid aqueous solution, and add the rinse solution to the granulator . Then drop 119g of microcrystalline cellulose into it for mixing, and stir evenly at a medium speed. Then, under high-speed stirring, the cutter is turned on for wet granulation. After the granulation is completed, fluidized bed drying is carried out, the inlet air temperature is 85°C, and the outlet air temperature is 60°C. Finally, the dried granules were mixed with 0.7g magnesium stearate for 30min, and 1000 No. 4 capsules were filled, and the weight of the capsules was measured to be about 120mg / grain, and the content of huperzine A was about 50 μg / grain.

Embodiment 2

[0018] Dissolve 1.2g of phosphoric acid in 60ml of water, take about 50ml to dissolve 0.05g of huperzine A, and then add it to the granulator. The remaining 10ml is the container for dissolving the main drug, and add the rinse solution to the granulator. Add 112g of lactose and 125g of microcrystalline cellulose into it again and mix, and stir evenly at a medium speed. Then, under high-speed stirring, the cutter is turned on for wet granulation. After the granulation is completed, fluidized bed drying is carried out, the inlet air temperature is 85°C, and the outlet air temperature is 60°C. Finally, the dried granules were mixed with 10 g of micropowder silica gel for 30 minutes, and 1000 No. 4 capsules were filled. The weight of the capsules was measured to be about 240 mg / capsule, and the content of huperzine A was about 50 μg / capsule.

Embodiment 3

[0020] Dissolve 1.24g of citric acid in 60ml of water, take about 50ml to dissolve 0.075g of huperzine A, and then add it to the granulator. The remaining 10ml of citric acid aqueous solution rinses the container for dissolving the main ingredient, and the rinse solution is added to the granulator. Put 180g of pregelatinized starch into it and mix, and stir evenly at a medium speed. Then, under high-speed stirring, the cutter is turned on for wet granulation. After the granulation is completed, fluidized bed drying is carried out, the inlet air temperature is 85°C, and the outlet air temperature is 60°C. Finally, the dried granules were mixed with 0.8 g of magnesium stearate and 7 g of talcum powder for 30 minutes, and 1,000 No. 4 capsules were filled. The weight of the capsules was about 185 mg / grain, and the content of huperzine A was about 75 μg / grain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com