Control method of ultra-high direct-current transmission voltage

A technology of UHV DC and transmission voltage, which is applied in the direction of converting AC power input to DC power output, output power conversion device, electrical components, etc., and can solve problems such as DC current low-frequency oscillation, voltage imbalance, and measurement circuit error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

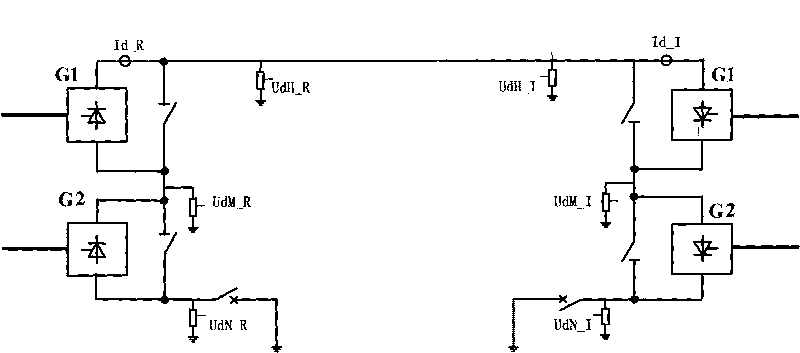

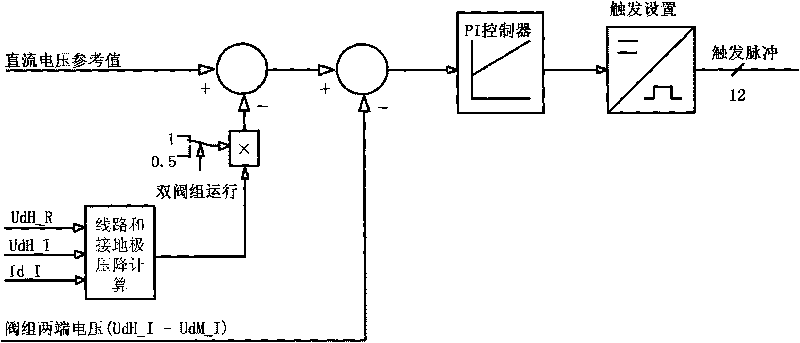

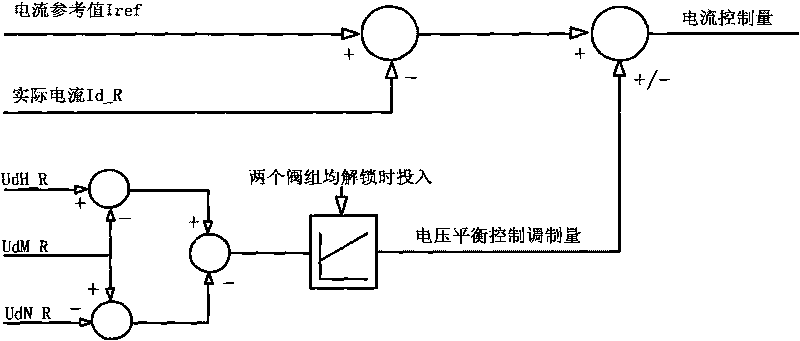

[0012] figure 1 The measurement signals UdH_R, UdH_I, Id_I used for constant voltage control on the inverter side are given in ; the measurement positions of the measurement signals UdH_R, UdM_R, UdN_R, Id_R used for voltage balance control.

[0013] Such as figure 1 , 2 , 3, firstly, in the pole control system on the inverter side, the voltage drop of the DC line and the grounding pole line is calculated through the DC current and DC voltage of the pole, the DC current of the opposite pole and the DC voltage of the opposite station. The DC voltage reference value does not need to be set to the voltage level of the entire pole on the rectification side, but to the voltage level of a single valve group on the rectification side. Subtract half of the voltage drop between the DC line and the ground electrode line from the DC voltage reference value to obtain the controller voltage reference value of each valve group. In the DC voltage control logic of each valve group, it is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com