Evaluation method of residual strength and service life under strengthening and damaging combined action

A technology of joint action and evaluation method, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve problems such as cars that have not been seen on the market, and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

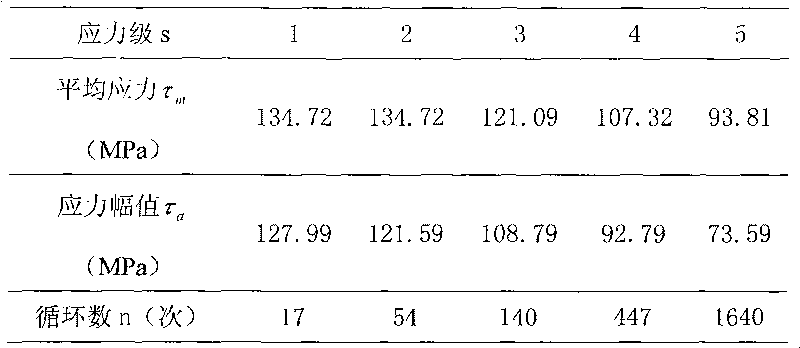

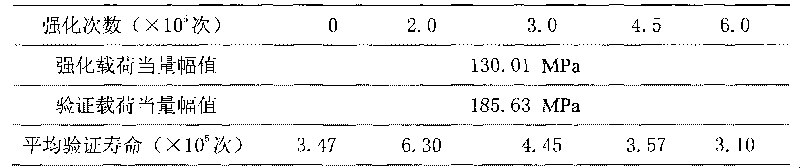

[0015] Taking the tractor half shaft (medium-strength parts. The material is 40Cr, the yield limit is 905.5MPa, and the tensile strength is 1000.3MPa) in the random load spectrum life test as an example. All tests are carried out on the electro-hydraulic servo torsional fatigue testing machine. The sample clamping method is fixed by the spline at the left end, and the pure torsional load is applied to the spline at the right end. The slight movement of the specimen in the axial direction is not restricted during the loading process, so as to ensure that the axial deformation of the specimen is not restricted when it is torsion. The evaluation method of residual strength and life under the joint action of tractor half shaft strengthening and damage is as follows:

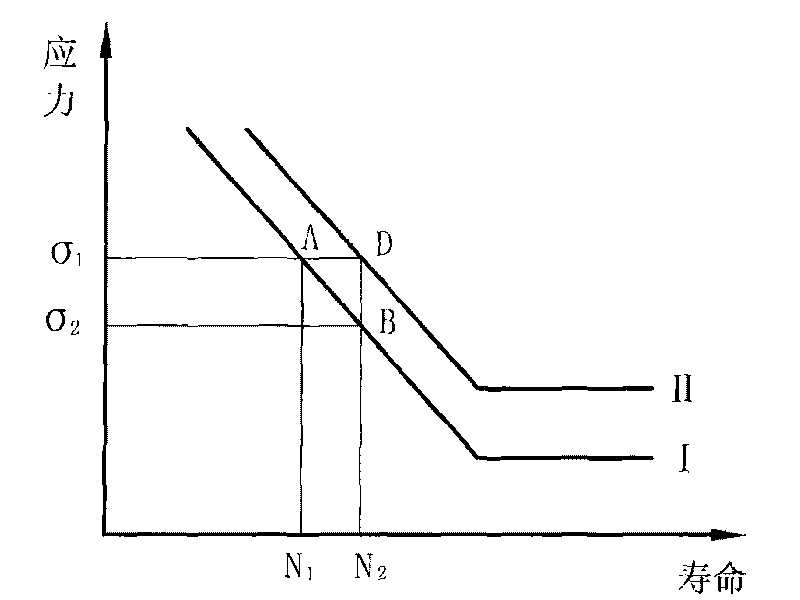

[0016] (A) Obtain the original stress-life curve of the material or part by test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com