Method for measuring volume of volume variation chamber of constant-pressure pressure leak calibration apparatus

A positive pressure leak hole and calibration device technology, which is applied in the direction of test/calibration device, measurement device, liquid/fluid solid measurement, etc., can solve the problem of the change between the measured value and the actual use value, unfavorable vacuum system maintenance, long measurement time period, etc. problems, to achieve the effect of maintaining and maintaining, the measurement process is simple and easy, and the measurement time period is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

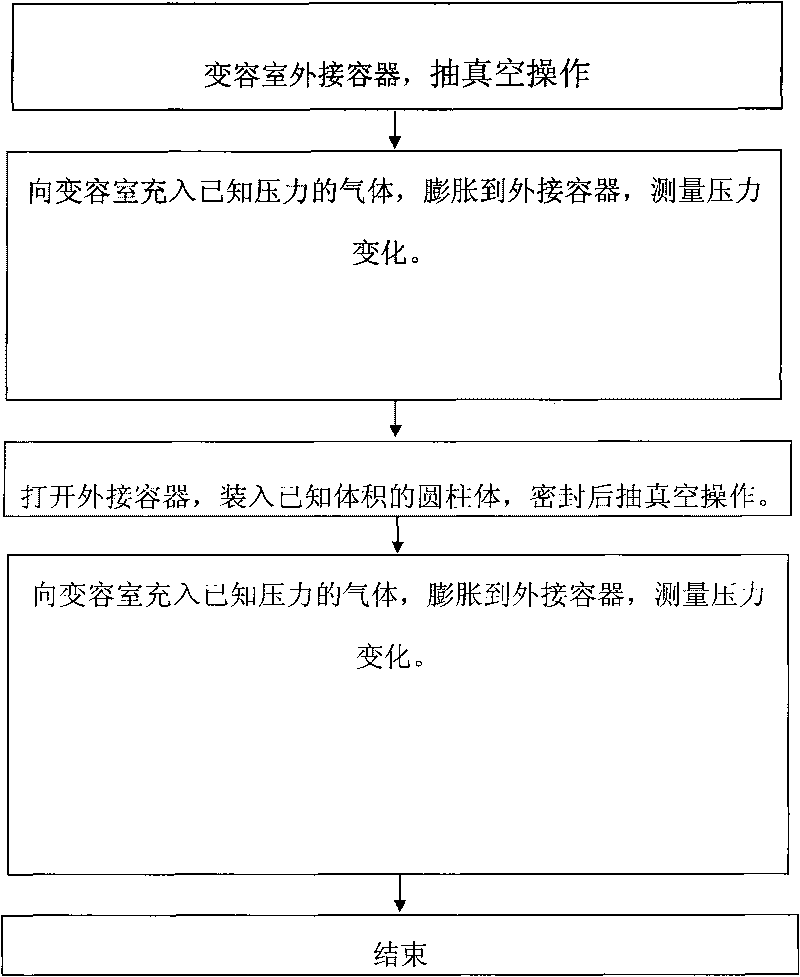

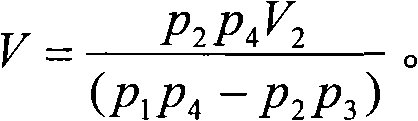

[0021] 1) Connect one end of the external container to the variable volume chamber through a vacuum valve, and seal the other end; the volume of the external container v 1 Determined by the volume of the variable volume chamber, v 1 1.5 times the volume v of the variable volume chamber;

[0022] 2) Simultaneously evacuate the external container and the variable volume chamber to the background, the vacuum degree is less than 0.01Pa, and the pressure p is introduced into the variable volume chamber 1 gas, p 1 The value is measured by pressure gauge, p 1 =11930.1Pa; then the gas expands to the external container, and the pressure after equilibrium is p 2 ,p 2 The value is measured by pressure gauge, p 2 =4288.4Pa;

[0023] 3) Open the other end of the external container and fill it with a known volume v 2 cylinder of v 2 =15.11ml; after loading into the cylinder, seal the external container, and then vacuumize the variable volume chamber and the external container to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com